Distributed feedback lasers formed via aspect ratio trapping

a feedback laser and aspect ratio technology, applied in the field of semiconductor device formation, can solve problems such as defect generation, and achieve the effects of reducing the number of gratings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

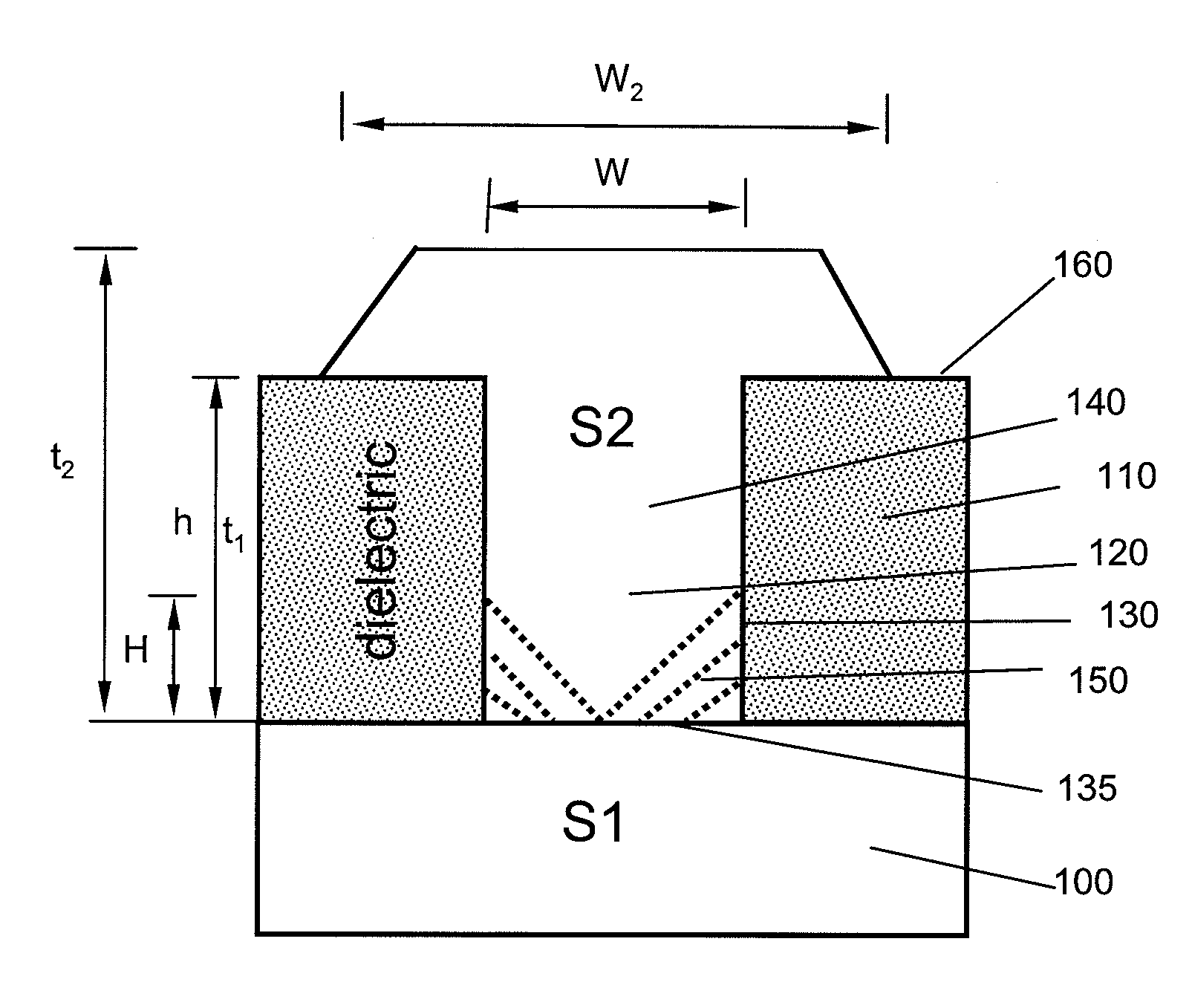

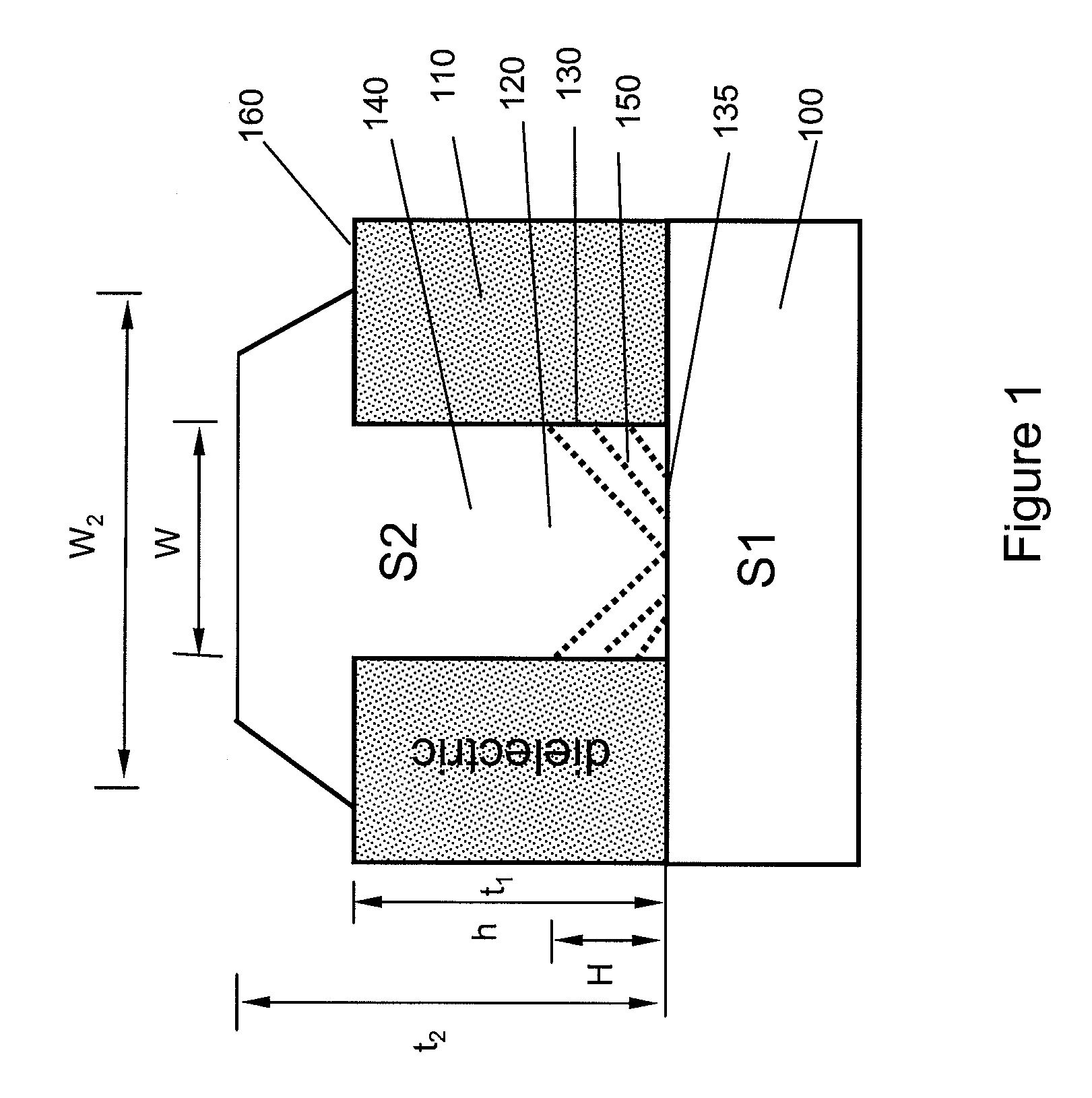

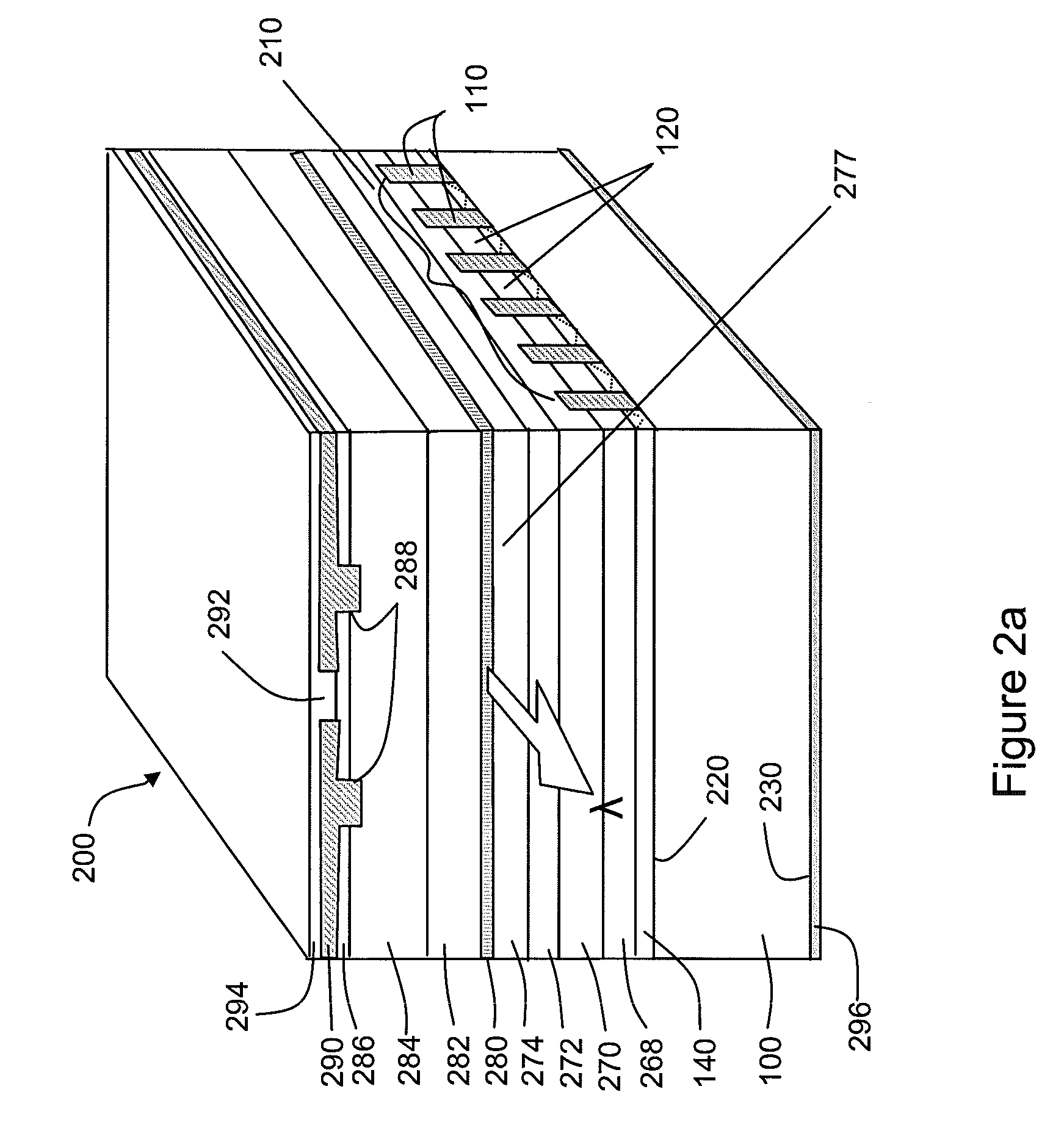

[0023]Referring to FIG. 1, a method for forming a relatively low defect or defect-free semiconductor material on a lattice-mismatched substrate is illustrated. A substrate 100 includes a first crystalline semiconductor material S1. The substrate 100 may be, for example, a bulk silicon wafer, a bulk germanium wafer, a semiconductor-on-insulator (SOI) substrate, or a strained semiconductor-on-insulator (SSOI) substrate. The substrate 100 may include or consist essentially of the first semiconductor material S1, such as a group IV element, e.g., germanium or silicon. In an embodiment, substrate 100 includes or consists essentially of n-type (100) silicon. The substrate 100 may include a material having a first conductivity type, e.g., n+Si.

[0024]A dielectric layer 110 is formed over the semiconductor substrate 100. The dielectric layer 110 may include or consist essentially of a dielectric material, such as silicon nitride or silicon dioxide. The dielectric layer 110 may be formed by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com