Coating composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

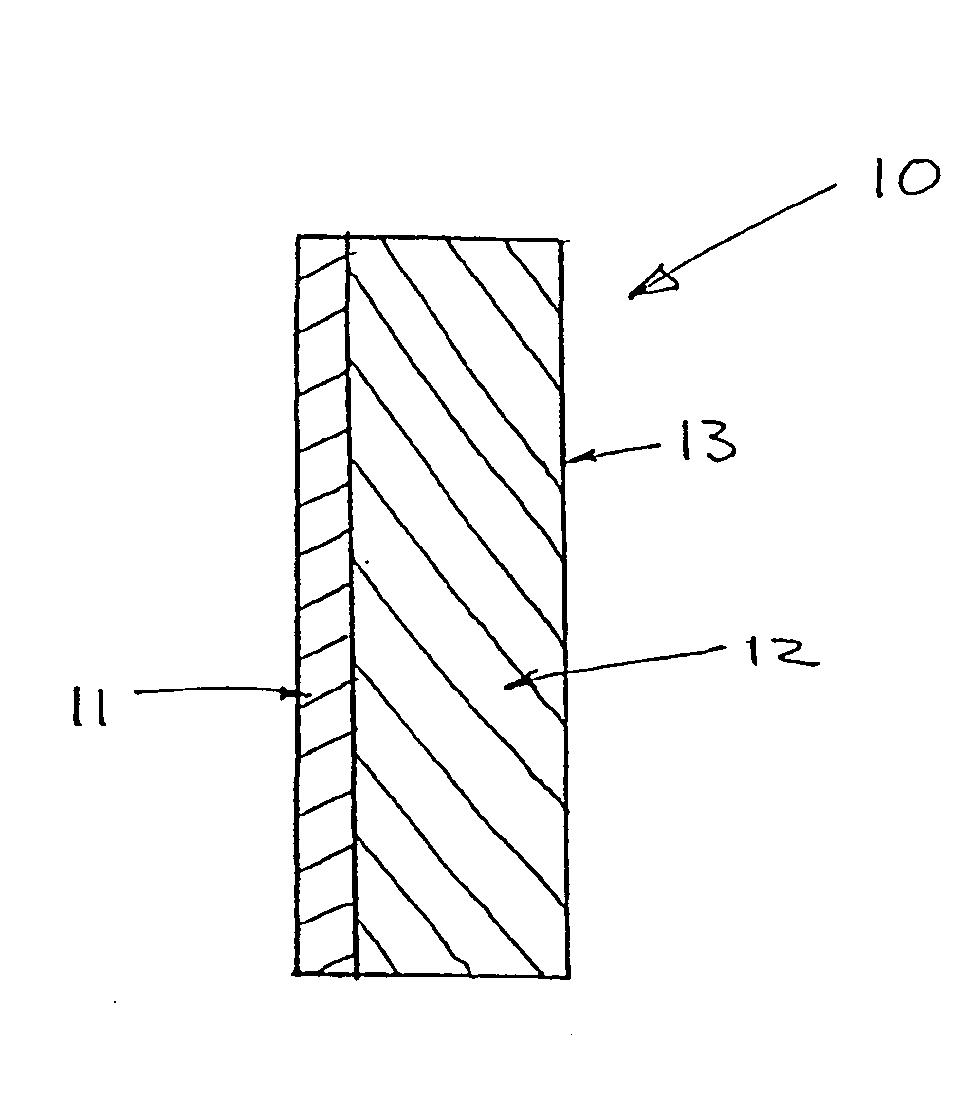

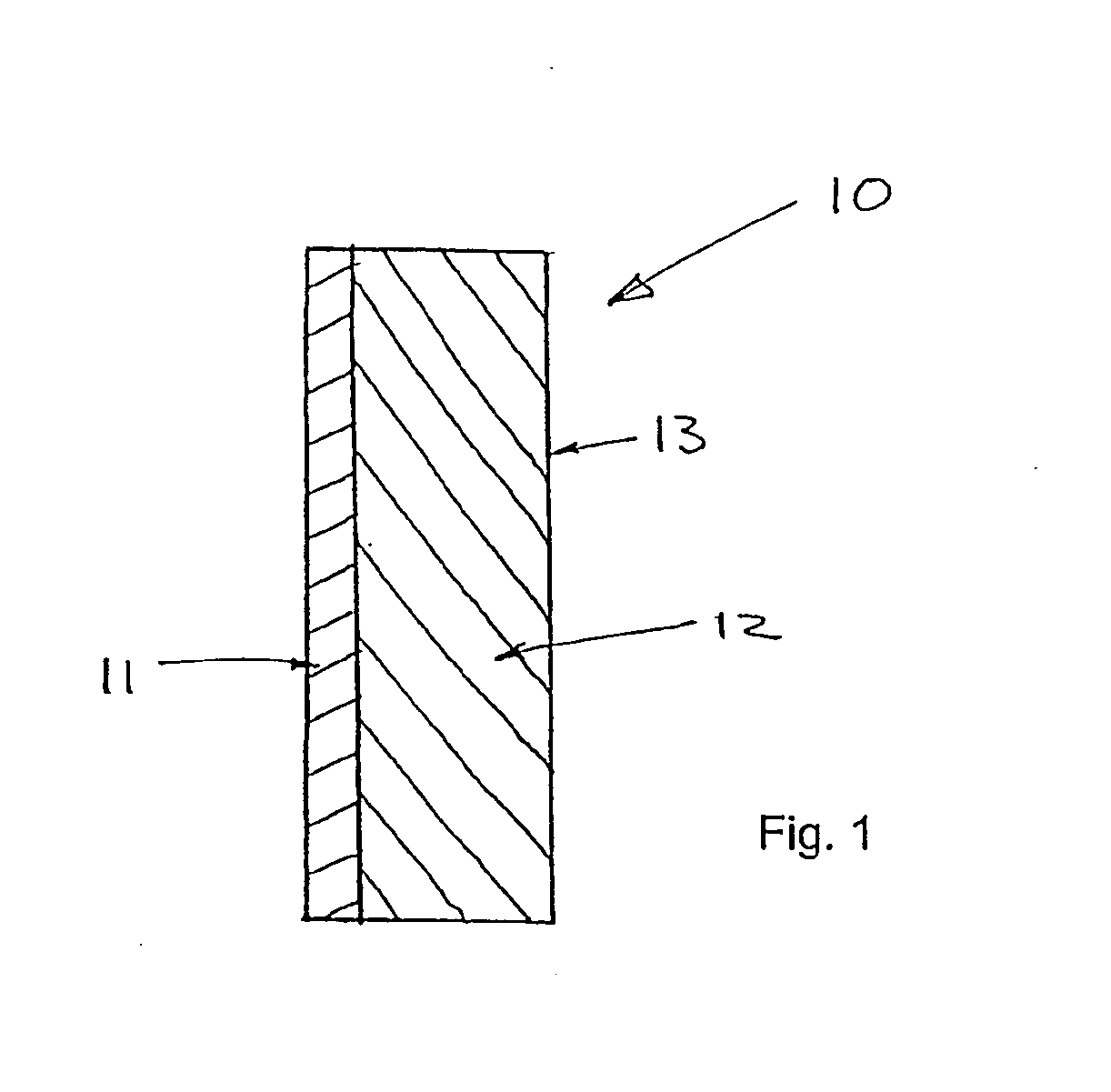

[0051]A cross-sectional view of the samples used in the experiments described herein is shown in FIG. 1. The sample 10 comprises a coating 11 applied to a surface of a substrate 12.

[0052]In all of the experiments described herein, other than the experiment involving window film coatings applied to glass sheets, the substrate 12 consisted of a steel plate of dimensions 200×300×0.9 mm. On one 200×300 mm surface of the steel substrate 12, a coating 11 was formed. The opposite 200×300 mm surface 13 of the steel substrate 12 was coated with a thin layer of conventional black paint. Such samples can be considered representative of coatings applied to structures such as buildings and vehicles.

[0053]To allow a comparison of the performance of coatings formed from coating compositions according to the present invention, experiments were initially undertaken by the present inventors on comparison or reference samples. A coating composition was prepared by adding cellulose particles at a ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com