Photosensor

a photosensor and flat panel technology, applied in the field of flat panel photosensors, can solve the problems of low spatial resolution of the pickup tube, low sensitivity, and inadequacies of instantaneous us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

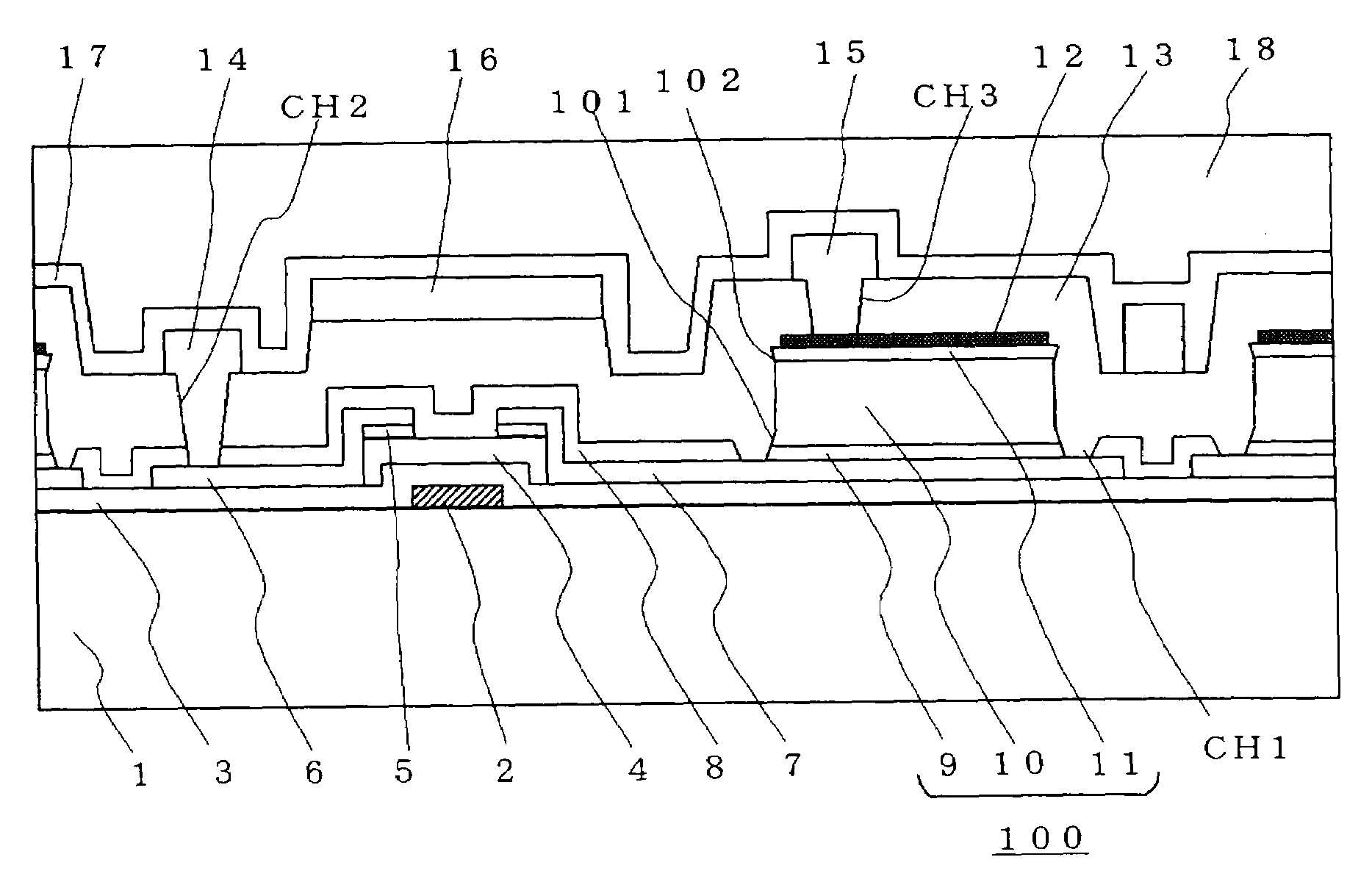

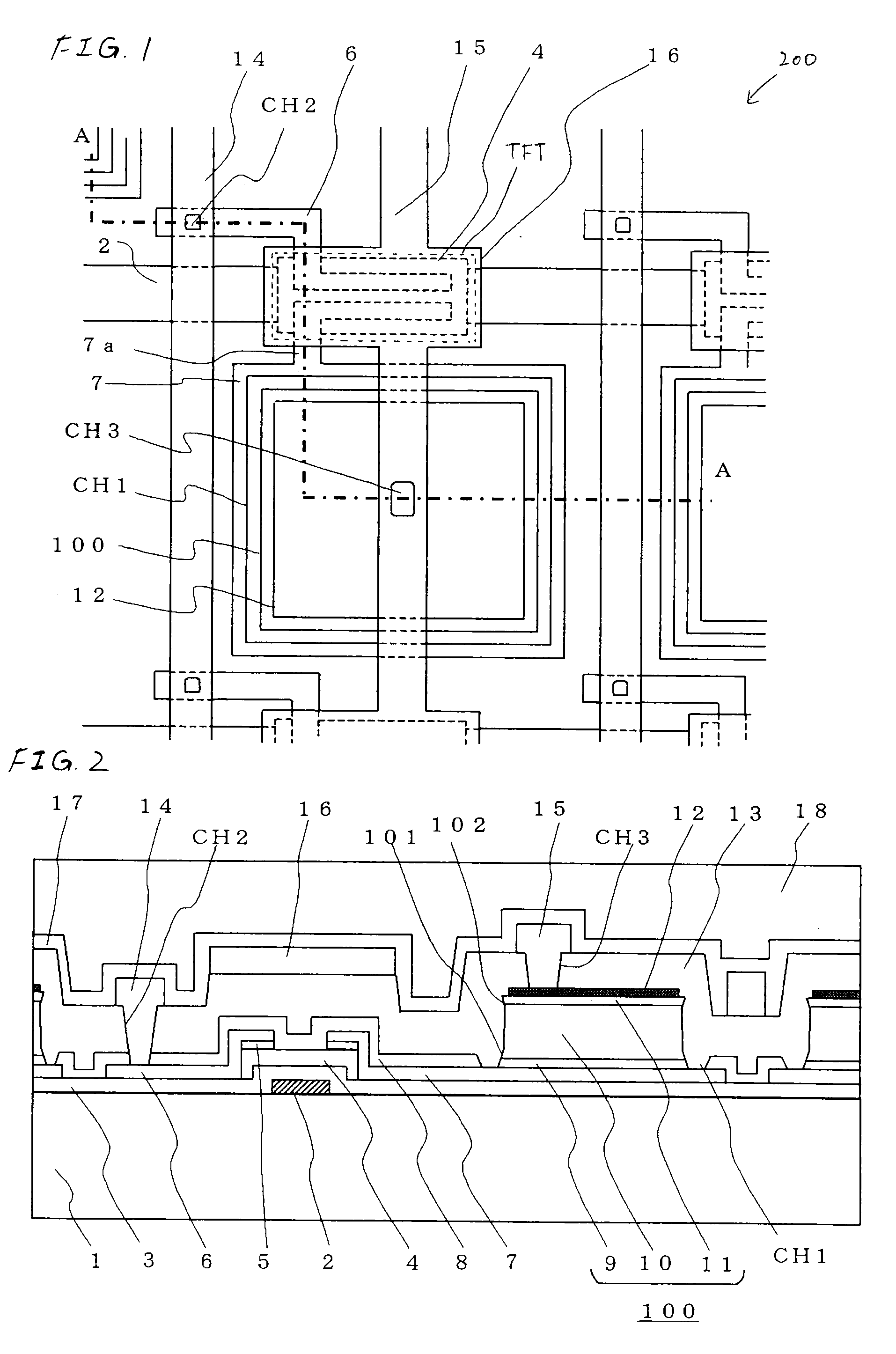

[0032]The preferred embodiments of the present invention will be specifically described while referring to drawings. FIG. 1 is a plan view of a TFT array substrate 200 provided for a photosensor according to a first embodiment of this invention. FIG. 2 is a cross-sectional view of a portion indicated by A-A in FIG. 1.

[0033]A gate electrode 2 is made of metal that contains aluminum as the primary element, and is formed on a glass substrate 1 that is an insulating substrate. As metal that contains aluminum as the primary element, an Al alloy that contains Ni, such as AlNiNd, AlNiSi or AlNiMg, i.e., an Al—Ni alloy is employed. However, another aluminum alloy may be employed, or instead of Al, Cu may be employed as a low electrical resistant metal material. Further, the gate electrode 2 may be provided by laminating metal films. A gate insulating film 3 is deposited to cover the gate electrode 2, and a semiconductor layer 4 is formed opposite the gate electrode 2. An n+a-Si:H ohmic cont...

second embodiment

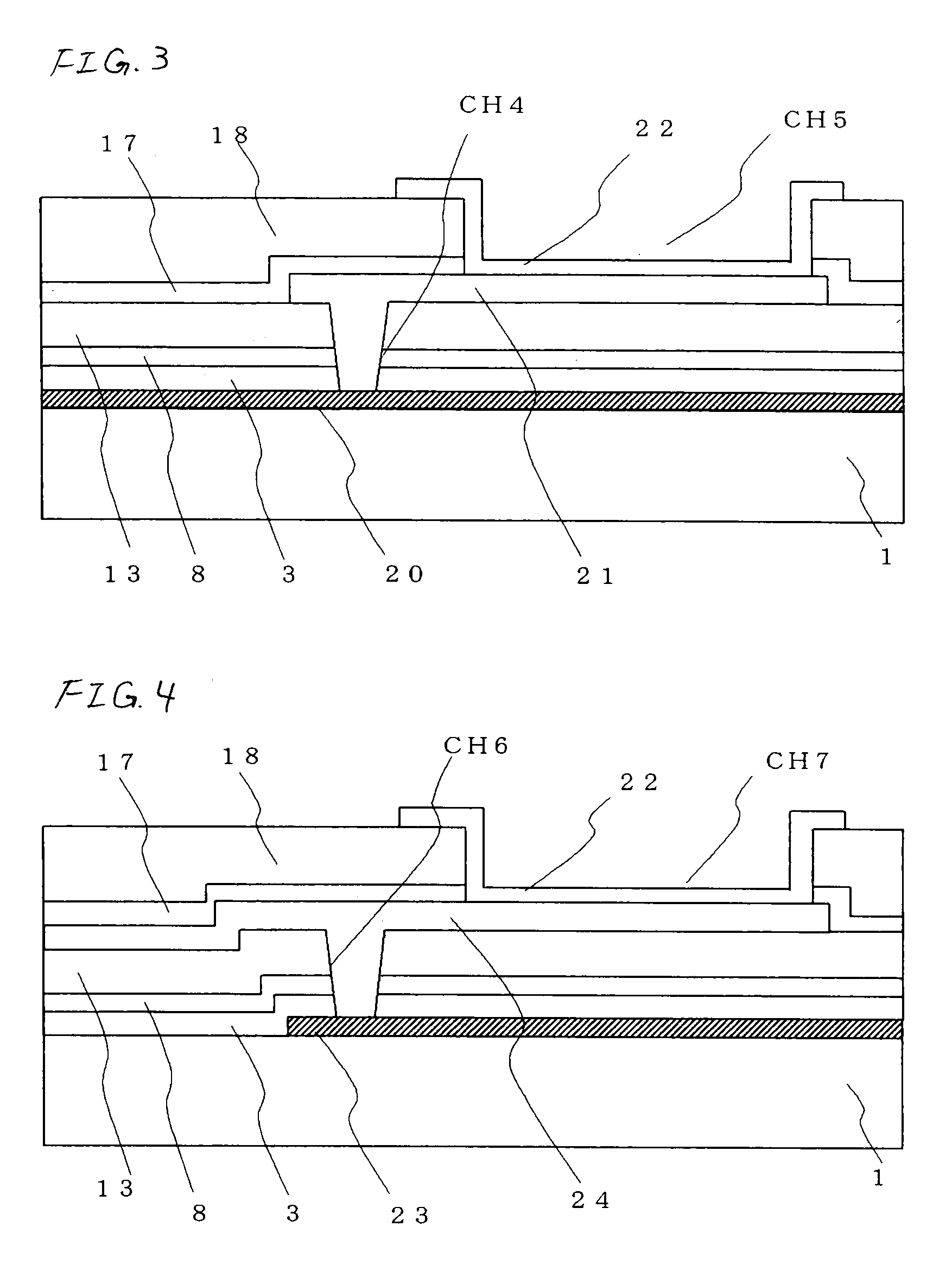

[0069]In the first embodiment, depending on an etching condition, there is a case wherein, in the processing for forming the contact hole CH1 that connects the drain electrode 7, which serves as the lower electrode for the photodiode 100, to the amorphous silicon film 9, a polymer may be generated by the element of an etching gas and be attached again to the drain electrode 7. In this state, when the P-doped amorphous silicon film 9, the intrinsic amorphous silicon film 10 and the B-doped amorphous silicon film 11 are deposited to constitute the photodiode 100, the adhesion to the drain electrode 7 is deteriorated and the amorphous silicon film might peel off.

[0070]According to a second embodiment of the present invention, a leak current of a photodiode 100 is inhibited, and an amorphous silicon film is prevented from peeling off. This embodiment will now be described while referring to FIGS. 9 and 10. FIG. 9 is a plan view of a TFT array substrate 200 provided for a photosensor for...

third embodiment

[0075]In the second embodiment, the lower electrode 25 has been formed so that the pattern end completely covers the contact hole CH1. This is because of the following background. Assuming that the lower electrode 25 is smaller than the contact hole CH1, the drain electrode 7 underneath will be exposed by etching the lower electrode 25. In a case wherein the drain electrode 7 does not have etch selectivity relative to the lower electrode 25, the drain electrode 7 underneath would also be etched. Especially when the connection portion 7a of the drain electrode 7 is etched, a wire break will occur between the thin film transistor (TFT) and the photodiode 100. Therefore, etch selectivity relative to the drain electrode 7 is required for the material of the lower electrode 25, and the selection range of materials is narrowed. To avoid this problem, generally, the lower electrode 25 is formed larger than the contact hole CH1. That is, the lower electrode 25 is formed to cover the contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com