Method of manufacturing composite structure, impurity removal processing apparatus, film forming apparatus, composite structure and raw material powder

a technology of impurity removal and processing equipment, applied in the field of manufacturing composite structures, can solve the problem of being unable to use formed films as piezoelectric materials, and achieve the effect of suppressing the separation of films or the generation of hillocks and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

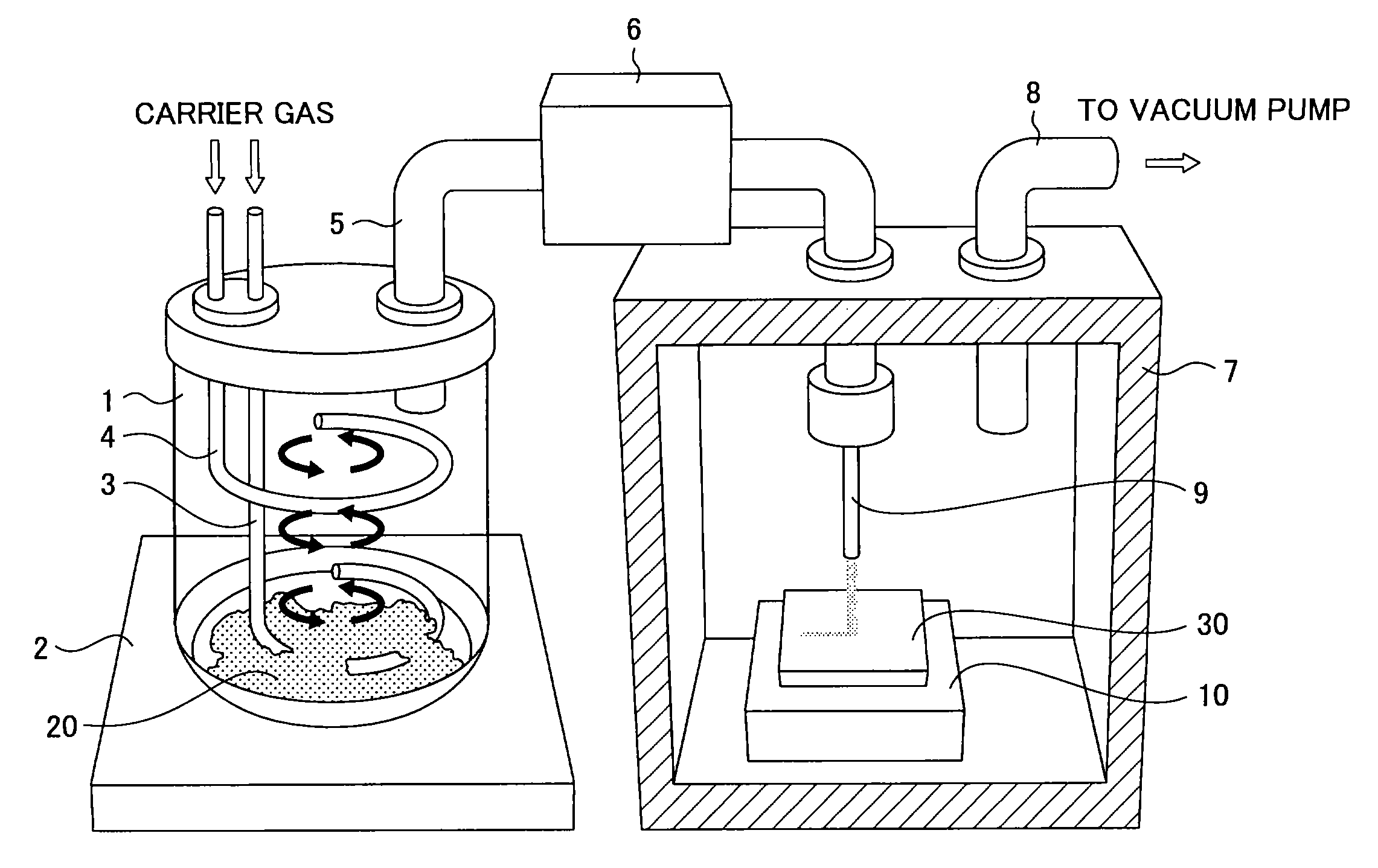

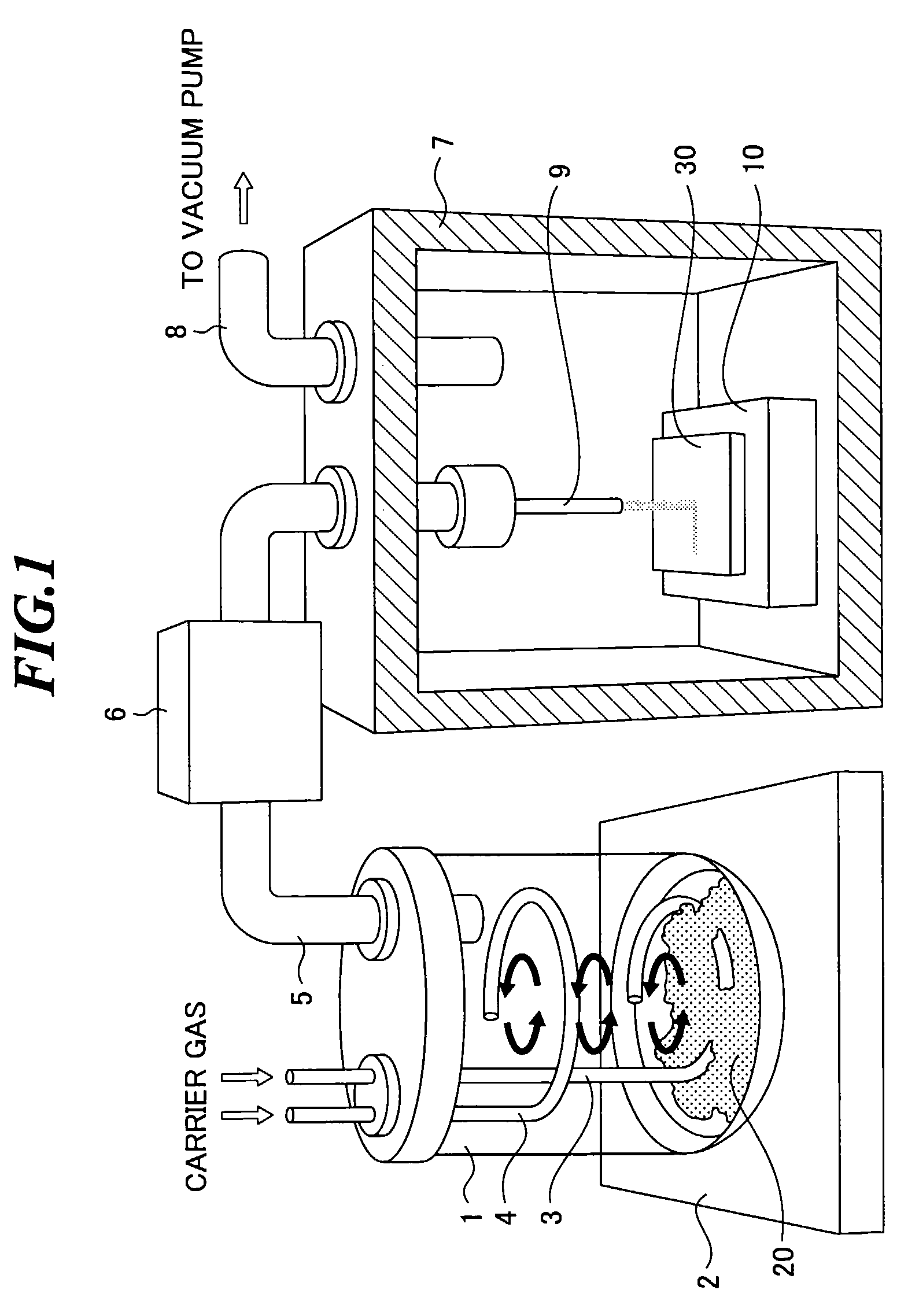

[0040]FIG. 1 is a schematic view showing a film forming apparatus using a method of manufacturing a composite structure according to the present invention. The film forming apparatus has an aerosol generating unit and a film forming unit. As shown in FIG. 1, the aerosol generating unit includes an aerosol generation chamber 1, a vibration table 2, a raising gas nozzle 3 and a pressure regulating gas nozzle 4. The film forming unit includes a film formation chamber 7, an exhaust pipe 8, an injection nozzle 9 and a substrate stage 10. Further, the film forming apparatus has an aerosol carrier pipe 5 and a decarburizing processing unit 6 provided between the aerosol generating unit and the film forming unit. The aerosol carrier pipe 5 and the decarburizing processing unit 6 construct, together with the aerosol generating unit, the impurity removal processing apparatus.

[0041]In the aerosol generation chamber 1, an aerosol is generated. Further, the aerosol generation chamber 1 is mounte...

second embodiment

[0111]Next, a method of manufacturing a composite structure according to the present invention will be explained.

[0112]Here, in the above explained first embodiment of the present invention, decarburizing processing of the raw material powder is performed in the middle of transportation of the aerosol generated in the aerosol generation chamber 1 as shown in FIG. 1 to the film formation chamber 7. However, the processing of generating an aerosol may be performed on the raw material powder that has been decarburizing processed in advance. In this case, at the time of film formation, a typical AD film forming apparatus (e.g., an apparatus formed by omitting the decarburizing processing unit 6 in the film forming apparatus as shown in FIG. 1) is used.

[0113]As a method of performing decarburizing processing on the raw material powder, as explained in the first embodiment, the method of heating the raw material powder by using a heater, the method of heating the raw material powder by ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| crystal particle diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com