Chemical suppressors and method of use

a technology of suppressors and suppressors, applied in the field of chemical suppressors, can solve the problems of increased noise, high voltage (50-500 volts dc) required, and detrimental to effective detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

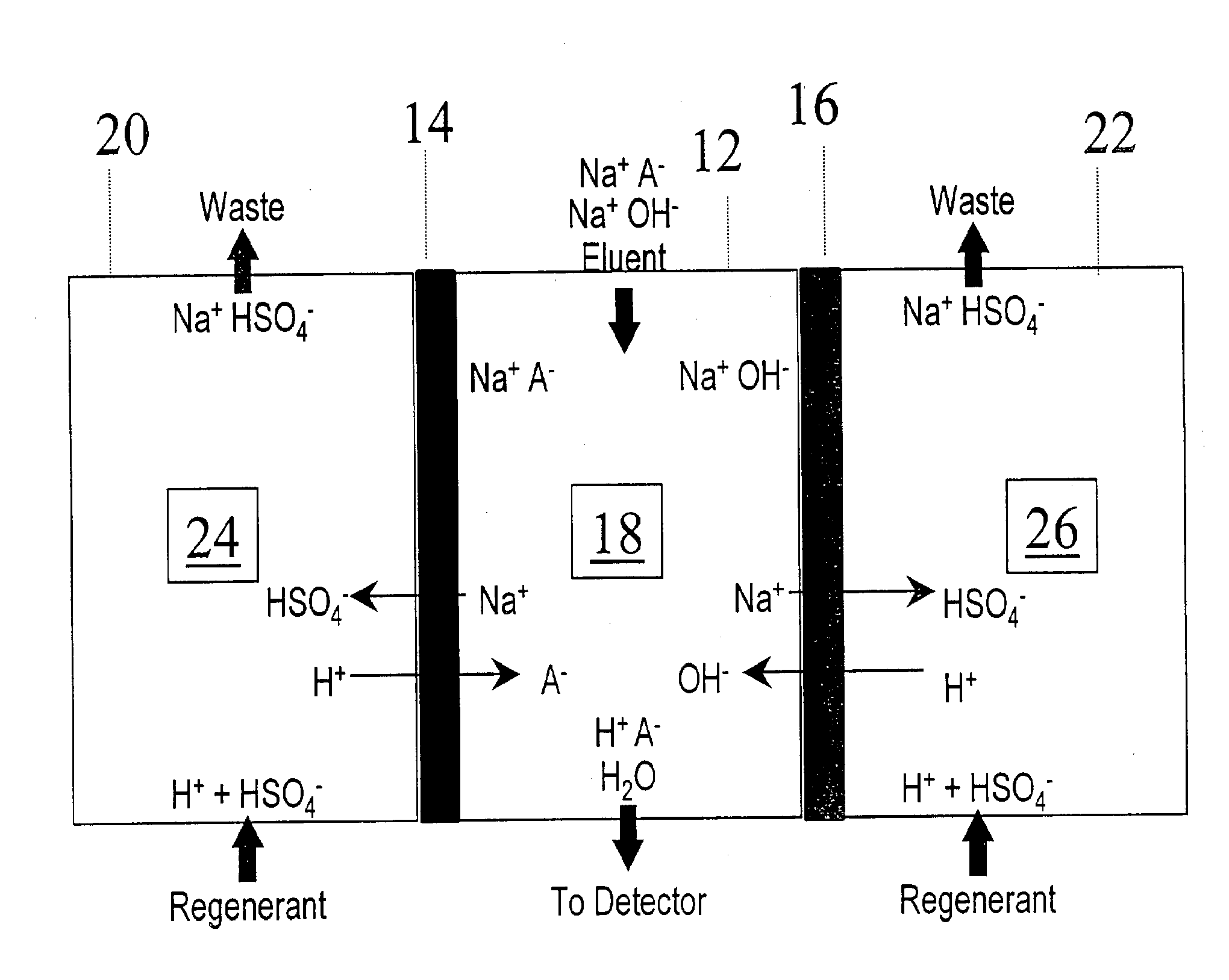

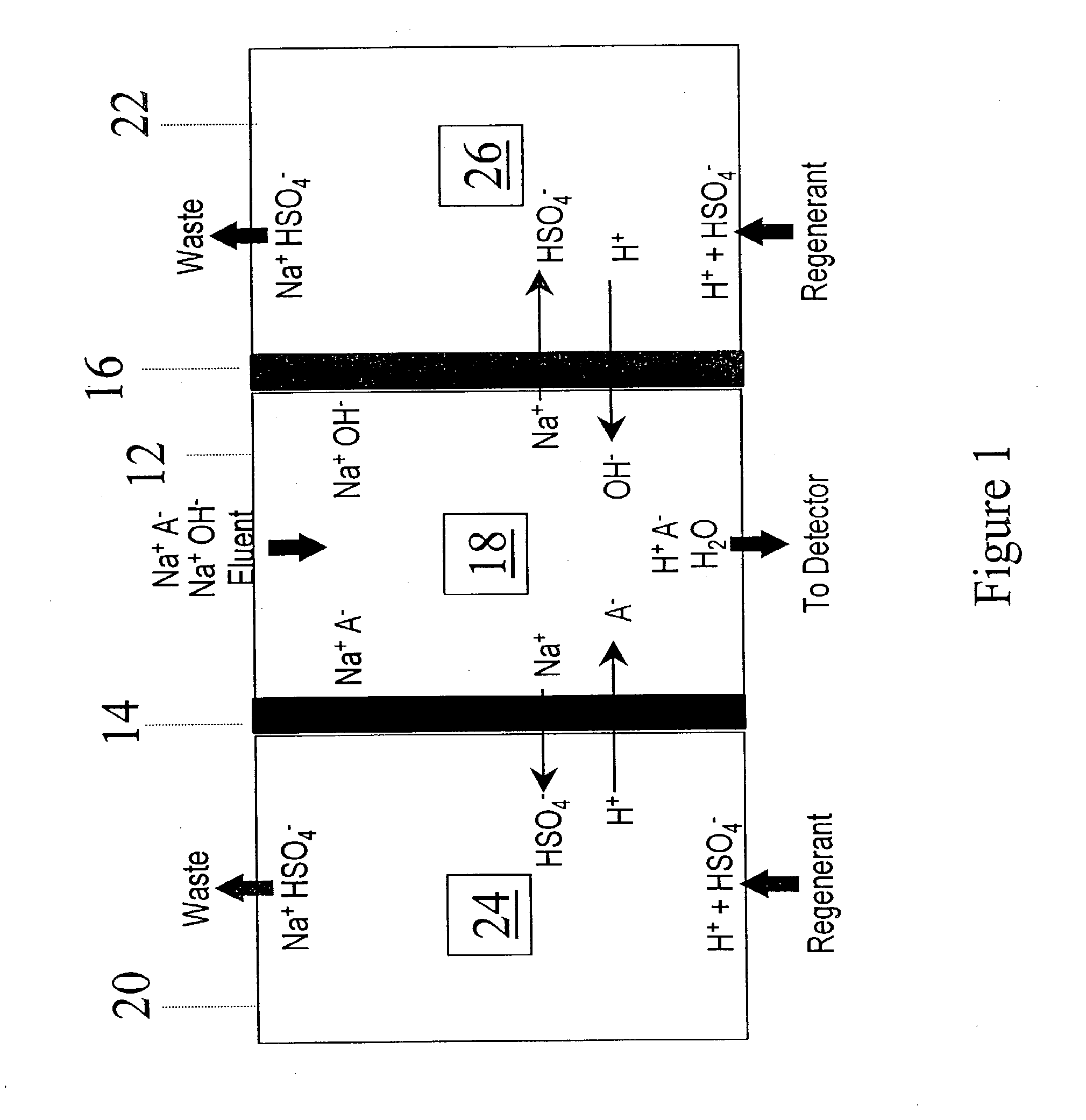

Image

Examples

example 1

[0048]The performance in terms of dynamic capacity of a standard AMMS III suppressor from Dionex Corporation was compared to a device of the present invention. The device of the present invention was assembled by fitting neutral regenerant screens in place of the functionalized cation exchange regenerant screens and using standard AMMS III suppressor components. A Dionex DX500 ion chromatography system was used for this testing. The dynamic suppression capacity was determined by pumping at 1 ml / min various concentrations of NaOH by conventional proportioning. The regenerant was 100 mN sulfuric acid pumped at 10 ml / min (conventional chemical suppression mode).

[0049]Results: The dynamic capacity of the standard AMMS III suppressor was measured as 170 ueqv / min. The device of the present invention showed a dynamic capacity of 210 ueqv / min which was an increase of 23% in capacity. Thus, removing the retention of the eluent cation in the regenerant chamber as per the current invention res...

example 2

[0050]The experimental setup was similar to Example 1 except the regenerant was 150 mN sulfuric acid and was dispensed using the displacement chemical regeneration approach of U.S. Pat. No. 6,436,719.

[0051]Results: The dynamic capacity under these conditions for a standard suppressor was 70 ueqv / min. The device of the present invention on the other hand showed a capacity of 90 ueqv / min. A 29% increase in capacity was observed as per the present invention.

example 3

[0052]The performance in terms of dynamic capacity of a standard CMMS III suppressor from Dionex Corporation was compared to a device of the present invention. The device of the present invention was assembled by fitting neutral regenerant screens in place of the functionalized regenerant screens using standard CMMS III suppressor components. A DX500 ion chromatography system was used for this testing. The dynamic suppression capacity was determined by pumping at 1 ml / min various concentrations of MSA by conventional proportioning. The regenerant was 100 mN tetrabutylammonium hydroxide base pumped at 10 mil / min (conventional chemical suppression mode). The dynamic capacity of the standard CMMS III suppressor was measured as 65 ueqv / min.

[0053]Results: The device of the present invention showed a dynamic capacity of 100 ueqv / min which was an increase of 53% in capacity. Thus, removing the retention of the anion in the regenerant chamber as per the present invention resulted in improve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltages | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com