Magnetoresistive element and method of manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

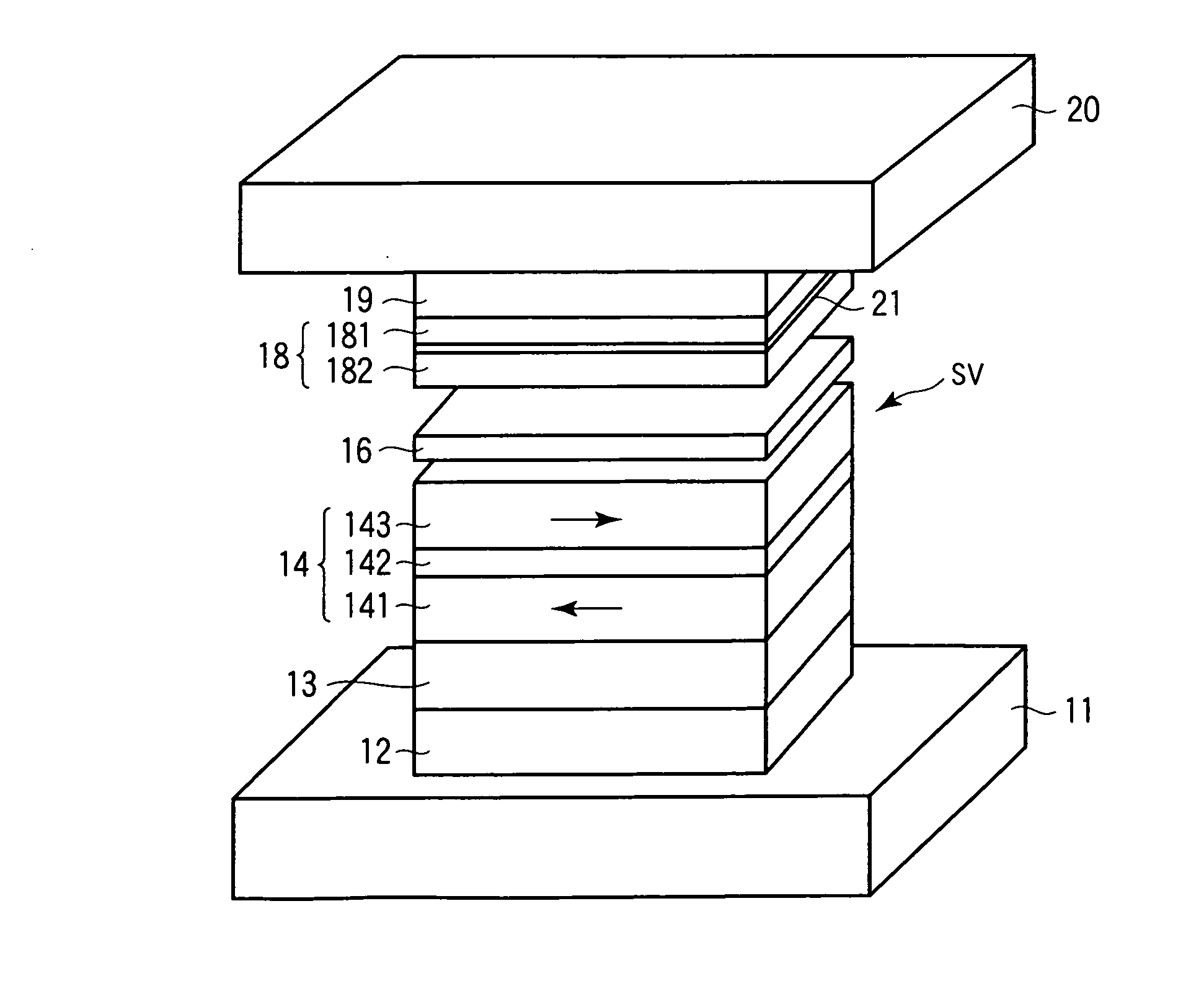

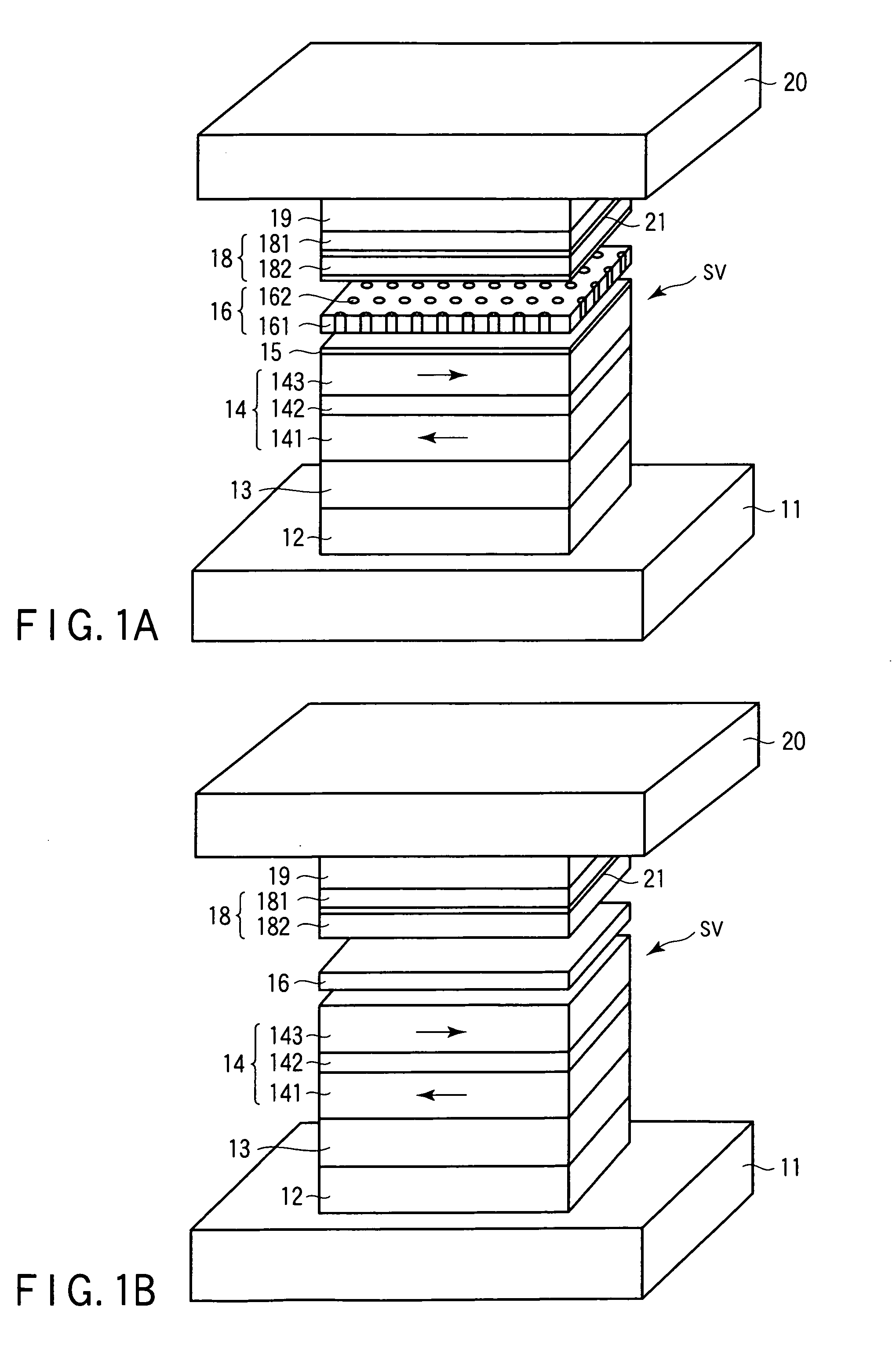

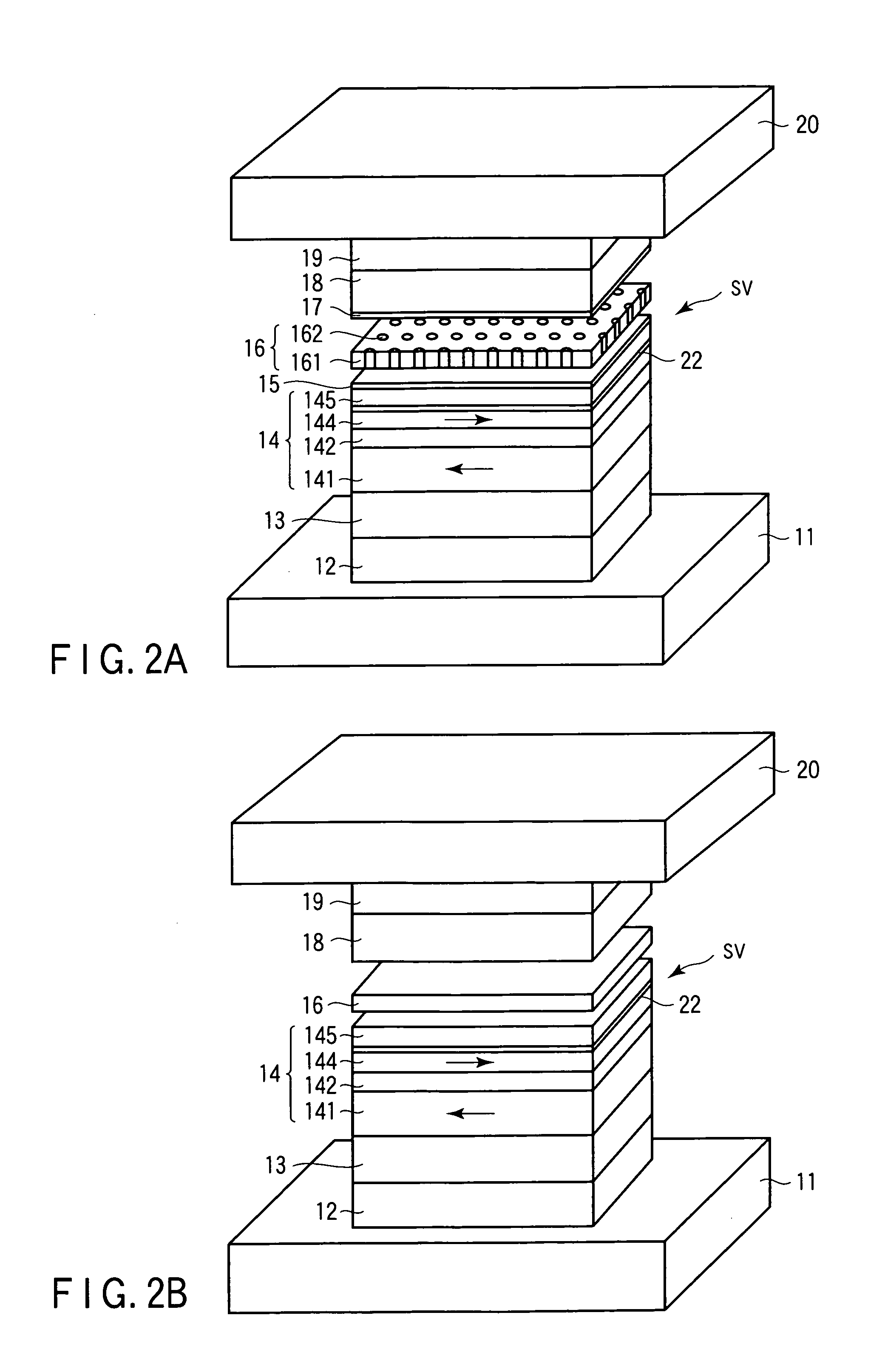

[0146]The magnetoresistive element shown in FIG. 1B was prepared in this example. The structure of the magnetoresistive element in Example 1 is as follows:

Lower electrode 11

Underlayer 12: Ta [1 nm] / Ru [2 nm]

Pinning layer 13: Ir22Mn78 [7 nm]

Pinned layer 14: Co90Fe10 [4 nm] / Ru [0.85 nm] / Co90Fe10 [4 nm]

Spacer layer (all metal) 16: Cu [3 nm]

Lower free layer 181: Co90Fe10 [2 nm]

SF layer 21: (nitride of Fe80Co20 [0.4 nm])×5 layers prepared by the method in FIGS. 4A to 4E

Upper free layer 182: Co90Fe10 [2 nm]

Cap layer 19

Upper electrode 20.

[0147]Now, a method of forming the free layer including the SF layer after the layers to the spacer layer 16 are deposited will be described. When the free layer including the SF layer is formed as in this example, a magnetic layer having half the thickness of the usual free layer is deposited and then the SF layer 21 is formed thereon. In this example, Co90Fe10 of 2 nm in thickness was deposited as the lower free layer 181.

[0148]Then, in the step of FIG. ...

example 2

[0150]A magnetoresistive element was prepared in the same manner as in Example 1 except that (nitride of Co64Fe16B20 [0.4 nm])×5 layers prepared by the method in FIGS. 4A to 4E was used as the SF layer 21.

example 3

[0151]A magnetoresistive element was prepared in the same manner as in Example 1 except that (nitride layer of Fe50Co50 [0.4 nm])×5 layers prepared by the method in FIGS. 4A to 4E was used as SF layer 21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com