Method for separating saturated and unsaturated fatty acid esters and use of separated fatty acid esters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

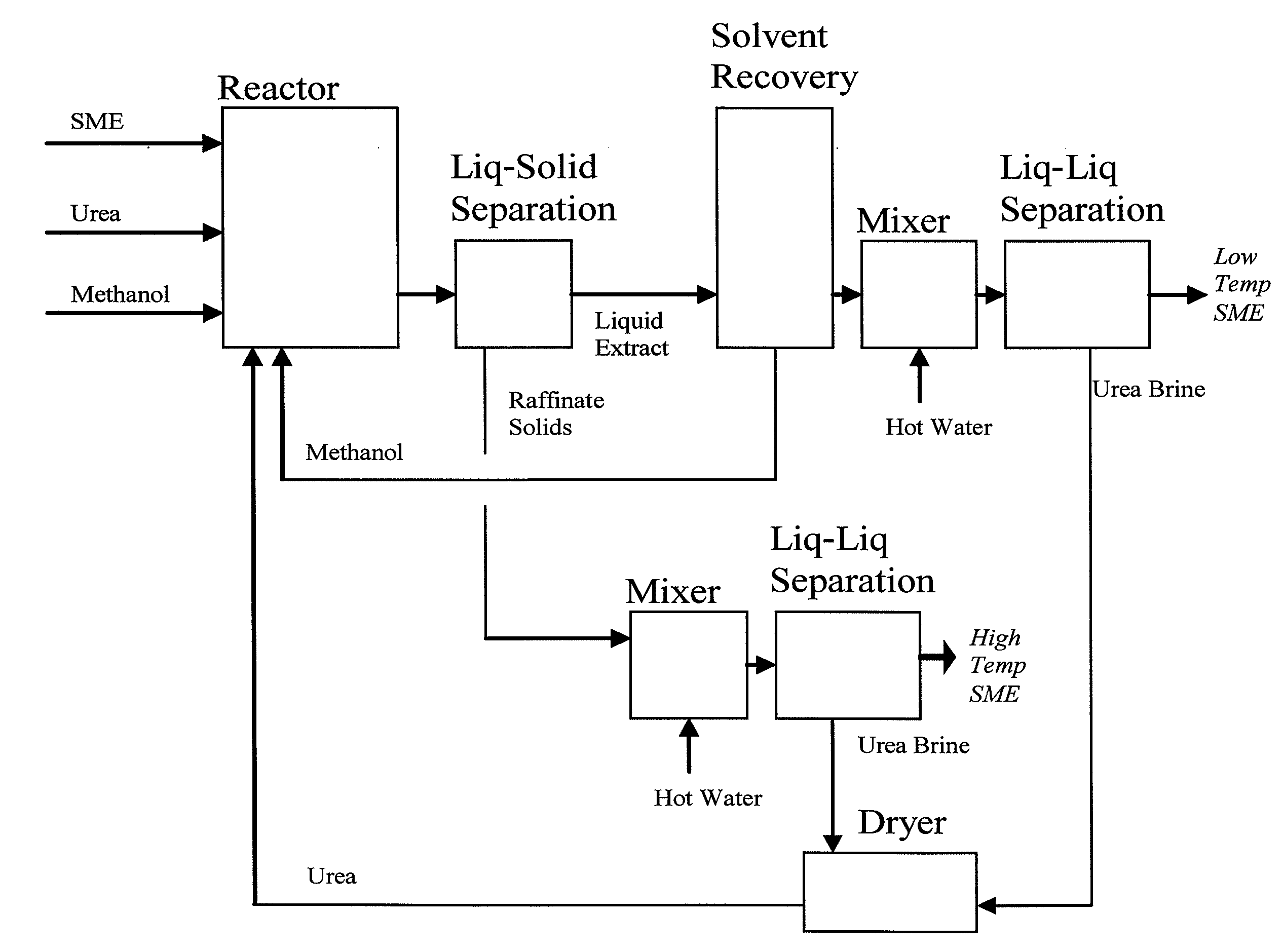

Method used

Image

Examples

example 1

[0101]Soy methyl ester prepared as described is analyzed for composition. The starting soy methyl ester had the composition and properties according to Table 5:

TABLE 5Percentage by WeightFatty Acid Methyl EsterCompositionMethyl Palmitate (C 16:0)9.2Methyl Stearate (C18:0)3.8Methyl Oleate (C18:1)23.5Methyl Linoleate (C18:2)55.3Methyl Linolenate (C 18:3)7.6Others0.7Total Saturates12.9C.P. (° C.)0

[0102]24.1 g of soy methyl ester and 10.1 g of urea were added to 160 mL of ethanol and the mixture was heated to 67° C., with constant stirring. A homogenous mixture was obtained with all the urea dissolving at this temperature. The mixture was then cooled at a rate of 1.2° C. / min to a final temperature of 20° C. The urea inclusion compounds (clathrates) formed were separated by filtration. The filtrate was then heated to 30° C. and 70% of the starting volume of ethanol was recovered via evaporation under vacuum. The remaining filtrate was twice washed with equal volumes of water (60° C., pH ...

example 2

[0103]24.1 g of soy methyl ester having the composition according to Table 5 and 18.0 g of urea were added to 160 mL of ethanol and the mixture was heated to 73° C., with constant stirring. A homogenous mixture was obtained with all the urea dissolving at this temperature. The mixture was then cooled at a rate of 1.2° C. / min to a final temperature of 20° C. The urea inclusion compounds formed were then separated by filtration. The filtrate was then heated to 30° C. and 52% of the starting volume of ethanol was recovered via evaporation under vacuum. The filtrate was twice washed with equal volumes of water (60° C., pH 3). 16.0 g of fractionated soy methyl ester (66.4% by wt of the starting soy methyl ester) was recovered with the composition and properties according to Table 7.

TABLE 7Percentage by WeightFatty Acid Methyl EsterCompositionMethyl Palmitate (C16:0)1.6Methyl Stearate (C18:0)0.0Methyl Oleate (C18:1)21.9Methyl Linoleate (C 18:2)69.5Methyl Linolenate (C 18:3)7.0Others0.03To...

example 3

[0104]24.1 g of soy methyl ester having the composition according to Table 5 and 16.0 g of urea were added to 160 mL of ethanol and the mixture was heated to 72° C., with constant stirring. A homogenous mixture was obtained with all the urea dissolving at this temperature. The mixture was then cooled at a rate of 1.3° C. / min to a final temperature of 30° C. The urea inclusions compounds formed were then separated by filtration. The filtrate was then heated to 30° C. and 63% of the starting volume of ethanol was recovered via evaporation under vacuum. The filtrate was twice washed with equal volumes of water (60° C., pH 3). 18.3 g of fractionated soy methyl ester (75.9% by wt of the starting soy methyl ester) was recovered with the composition and properties according to Table 8.

TABLE 8Percentage by WeightFatty Acid Methyl EsterCompositionMethyl Palmitate (C 16:0)2.3Methyl Stearate (C18:0)0.0Methyl Oleate (C18:1)22.5Methyl Linoleate (C18:2)68.5Methyl Linolenate (C 18:3)6.8Others0.02T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com