Negative electrode for nonaqueous secondary battery

a secondary battery and negative electrode technology, applied in the field of negative electrodes for nonaqueous secondary batteries, can solve the problems of battery cycle life reduction, reduce the effect of metallic materials, etc., and achieve the effect of low formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

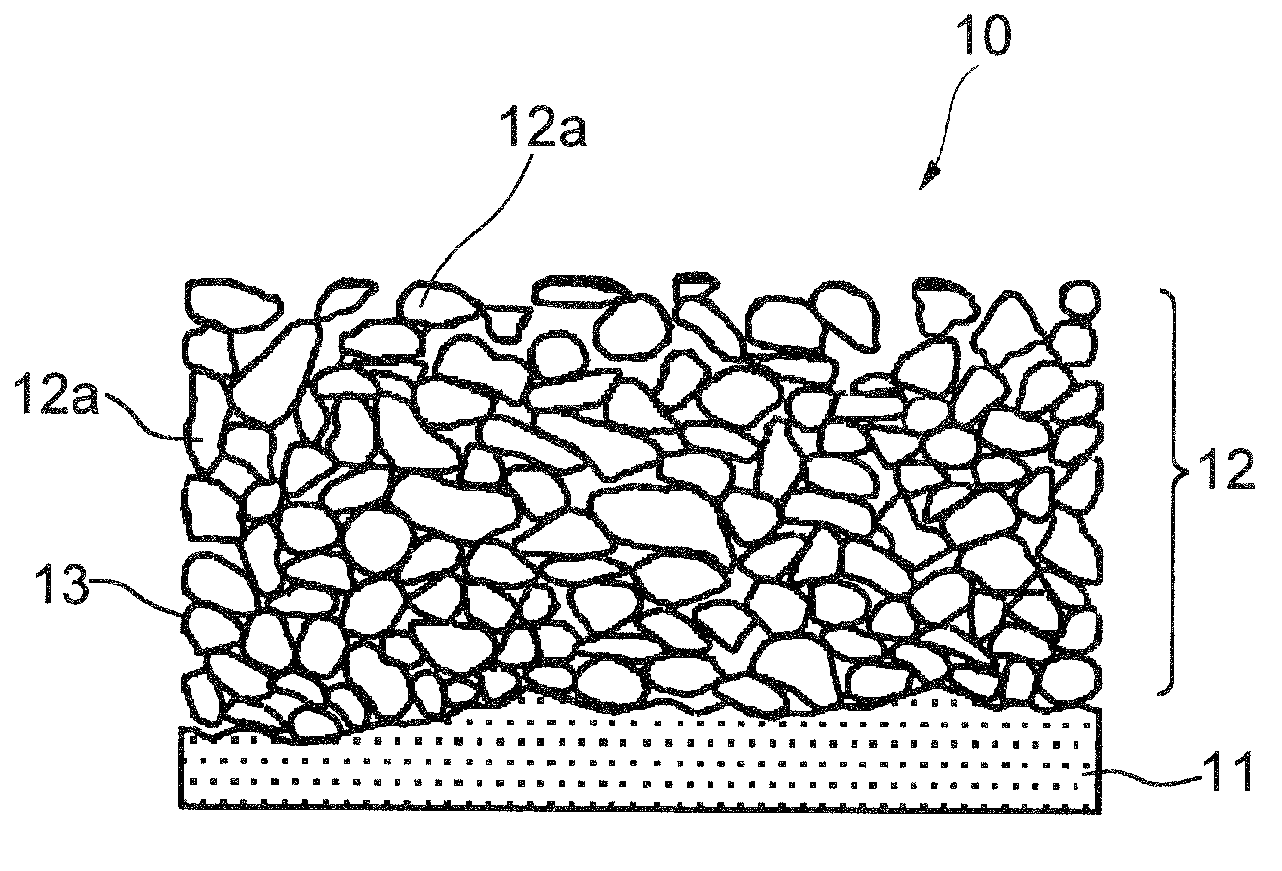

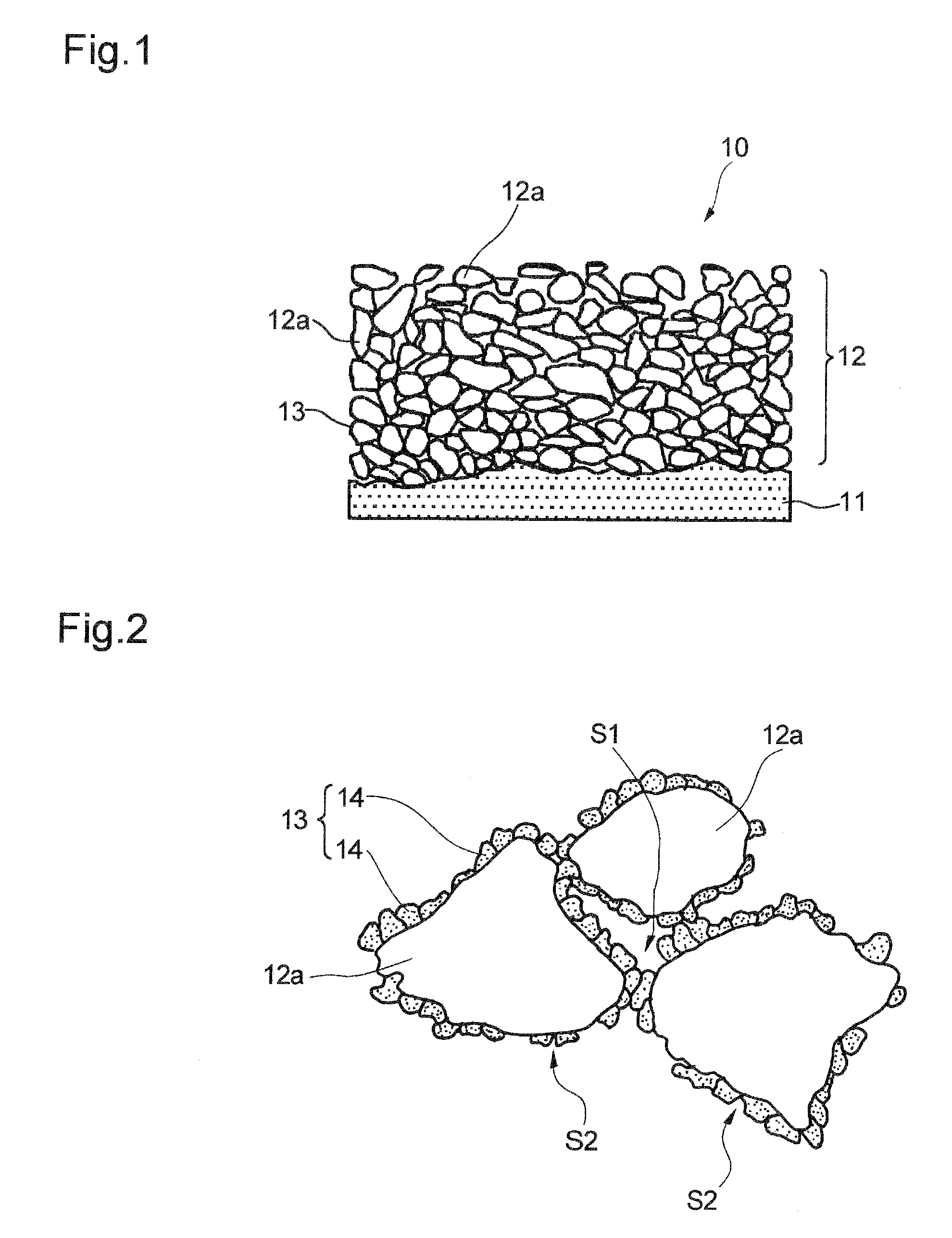

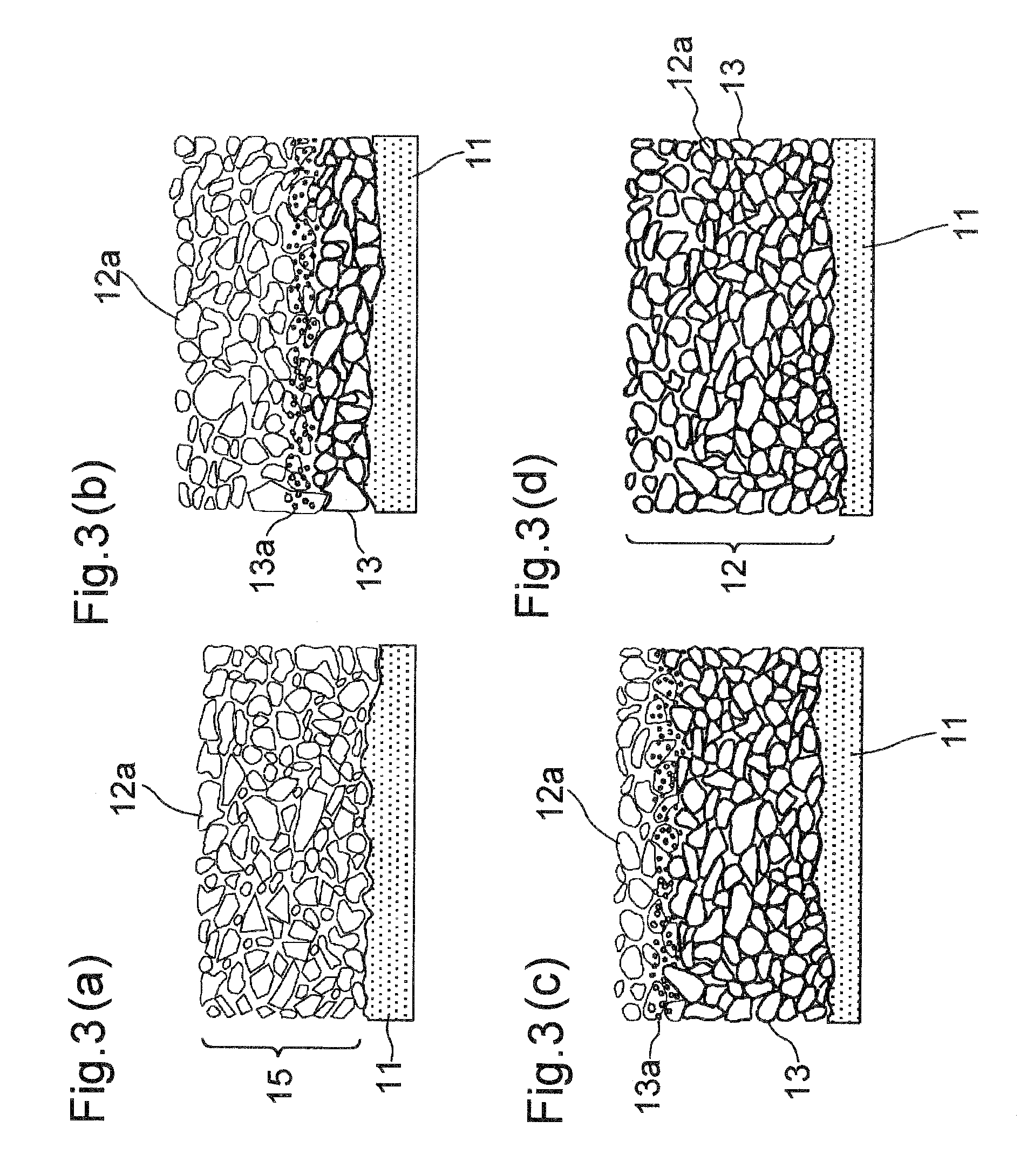

Image

Examples

example 1

[0072]A 18 μm thick electrolytic copper foil as a current collector was cleaned with an acid at room temperature for 30 seconds and washed with pure water for 15 seconds. A slurry of Si particles was applied to the current collector to a thickness of 15 μm to form a coating layer. The slurry contained the particles, styrene-butadiene rubber (binder), and acetylene black at a weight ratio of 100:1.7:2. The particles had an average particle size D50 of 2.5 μm and a particle size distribution D10 / D90 of 0.07. The average particle size D50 and particle size distribution D10 / D90 were measured using a laser diffraction scattering particle size analyzer Microtrack (Model 9320-X100) from Nikkiso Co., Ltd. The Si particles were found to be single crystals as observed by Pegasus System from EDAX.

[0073]The current collector having the coating layer was immersed in a copper pyrophosphate plating bath having the following composition, and the coating layer was penetration-plated with copper by e...

examples 2 to 5

[0082]A negative electrode was fabricated in the same manner as in Example 1, except for using Si single crystal grains having the average particle size D50 and particle size distribution D10 / D90 shown in Table 1 below as Si particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com