Method For Releasing Organics From Shale And Like Materials To Produce A Liquid Shale Fuel

a technology of organics and shale, which is applied in the direction of liquid carbonaceous fuels, hydrocarbon oil treatment, waste based fuels, etc., can solve the problems of environmental impact, low temperature and pressure operation, and low water consumption, and achieves low temperature, low water consumption, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

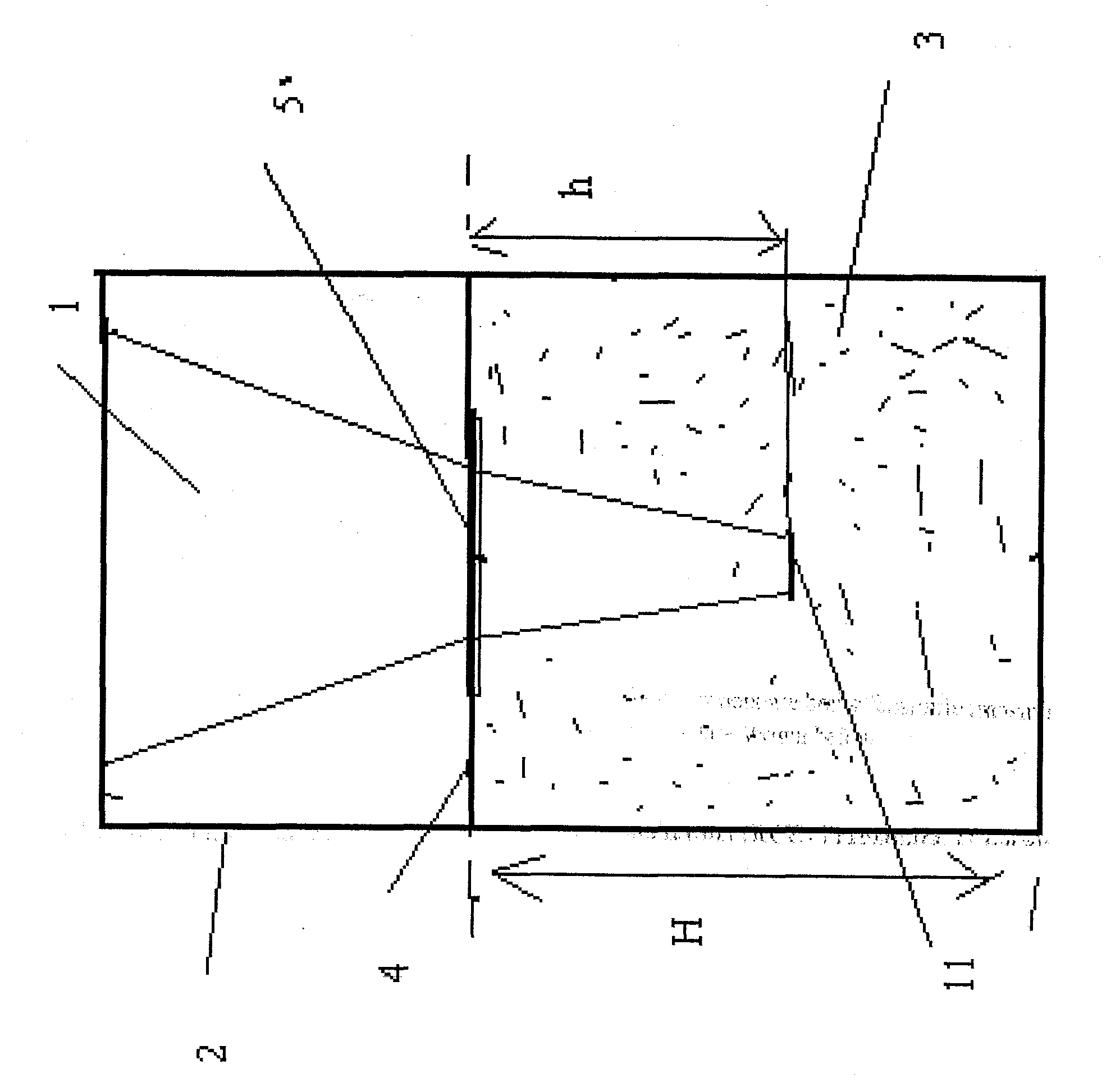

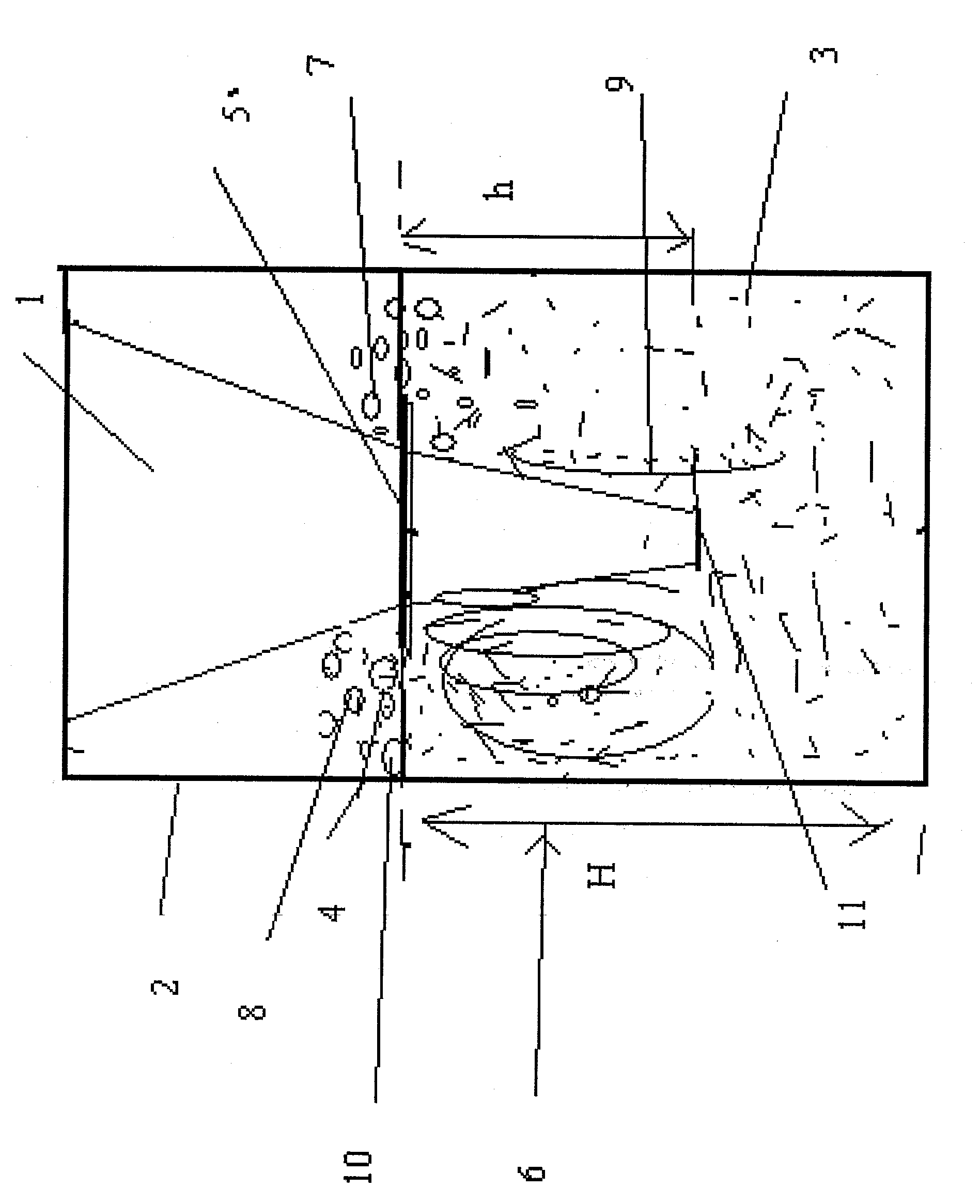

[0033]The organic release method according to the invention comprises a process for pulverizing shale oil into powdery grains by, for example, a mechanical means; mixing grains in a liquid and treatment of the mixture by vortical movements, wave movements, acoustical streams, or combinations thereof; foaming; removing the foam, which contains the organic materials of shale oil, from the mixture; mixing the foam containing organic materials with the liquid solvent, for example ethanol; and processing this mixture by vortical movements, wave movements, acoustical streams, or combinations thereof. The processing forms a liquid, which contains derivates of benzene (see Table 1) and light fractions of hydrocarbons, for example, Toluene, Xylene and others (see Table 2) that are released from organic materials of shale oil. The non-organic solids from the shale oil consist of, for example, Calcite, Clay, and minerals (see Table 3). The whole process takes place under ambient temperature an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com