Resistance heater based air heating device

a technology of resistance heater and air heating device, which is applied in the direction of domestic stoves or ranges, combustion types, applications, etc., can solve the problems of inconvenience, low thermal conductivity, and inability to meet the needs of consumers, and achieve low thermal diffusivity, low thermal conductivity, and high surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

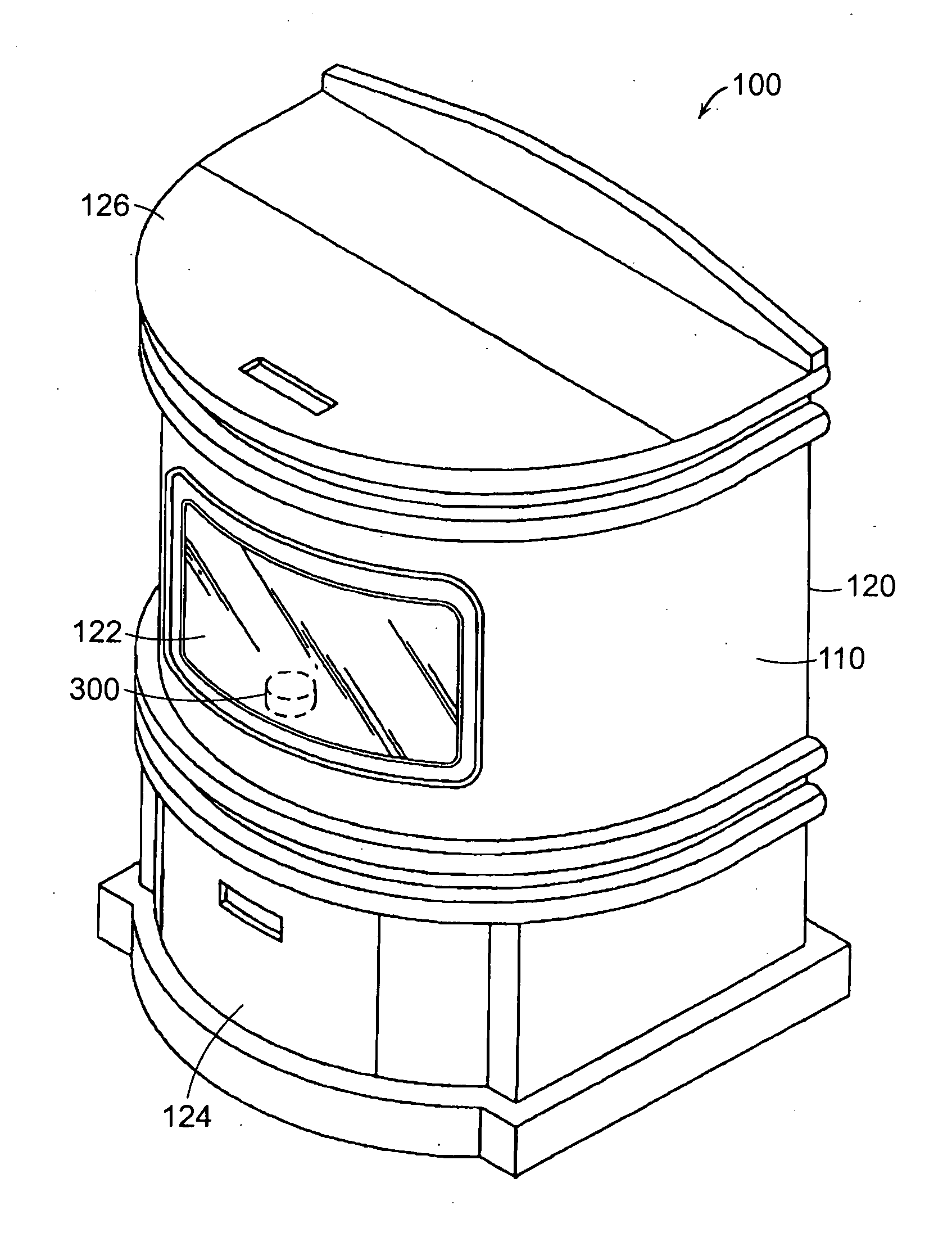

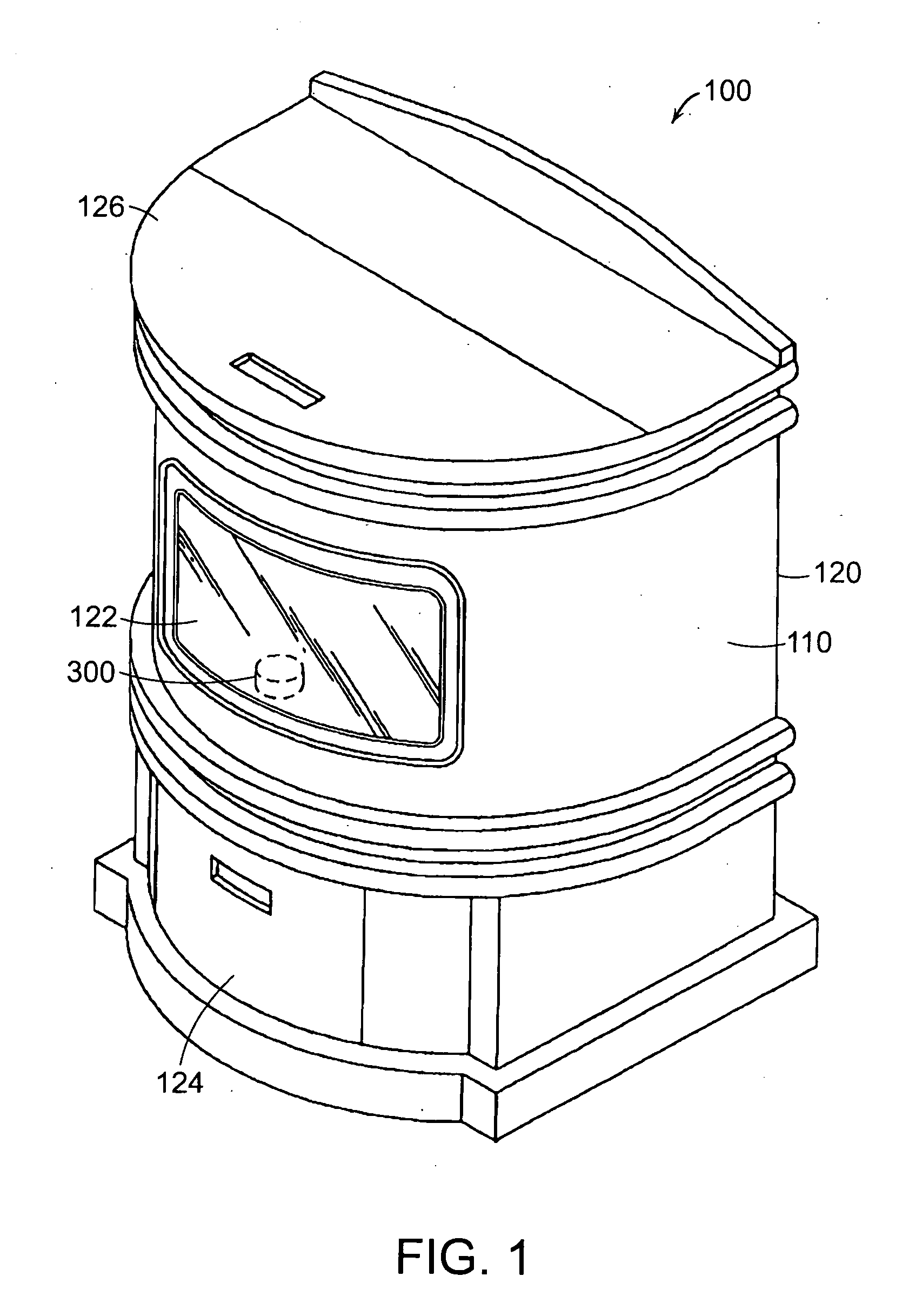

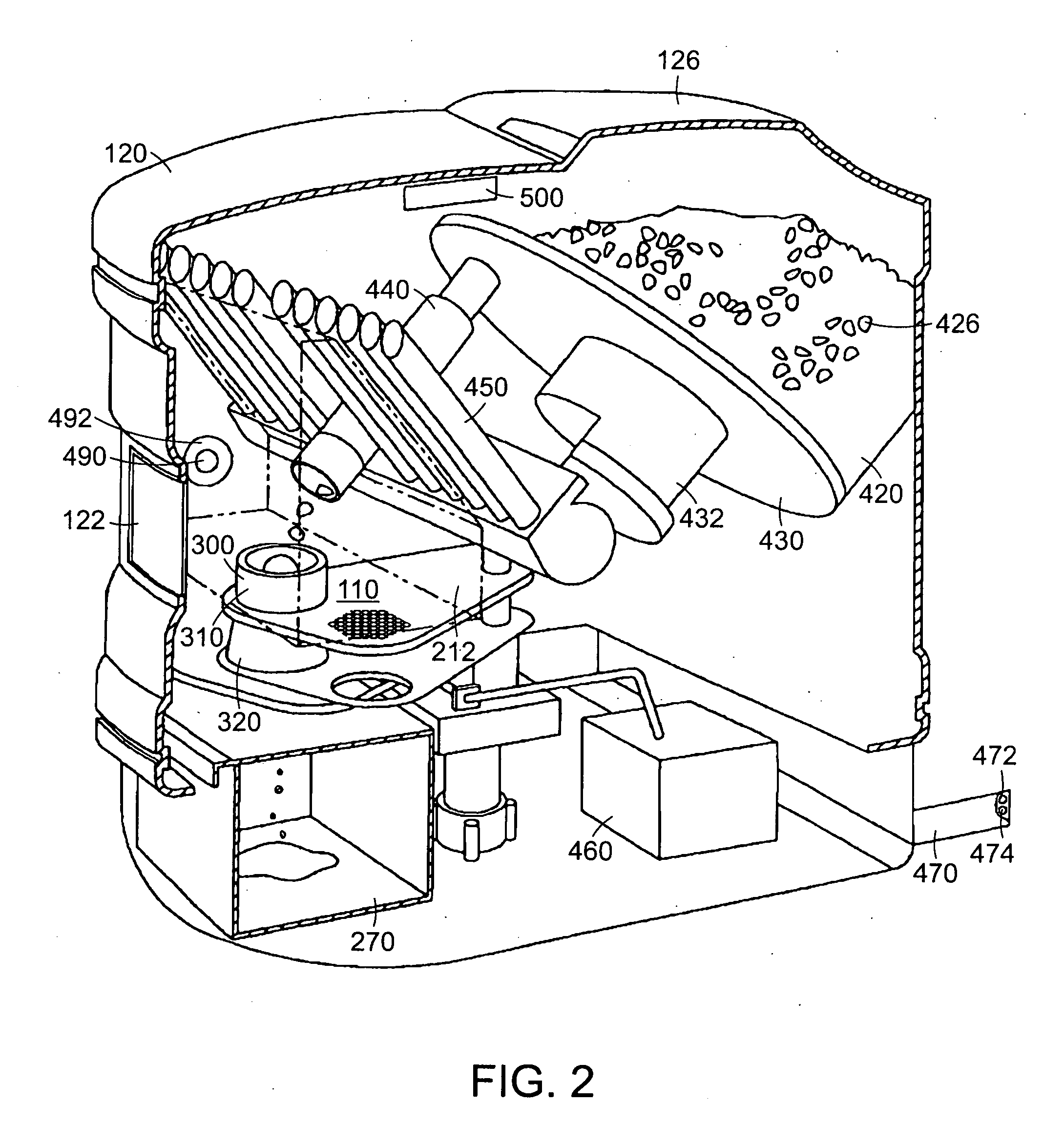

[0030]Referring now to the various figures of the drawing wherein like reference characters refer to like parts, there is shown in FIG. 1 an illustrative view an exemplary furnace 100 having a combustion chamber 110 in which is located a resistance heater air heating device 500 of the present invention. The furnace 100 includes a housing 120 and the combustion chamber 110 is within the housing 120. In the illustrated embodiment, at least a portion of the combustion chamber 110 a viewable through a window 122, which is sealed with respect to the housing 120. The housing 120 also includes an access panel 124 that allows access to a portion of the interior of the furnace 100 located below the combustion chamber. The access panel, in some embodiments, allows users to remove combustion products from the furnace 100. As shown more clearly in FIG. 4, the housing 120 also includes a hopper and a feed mechanism for controllably placing biomass combustibles into the combustion chamber 110. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com