Anisotropic conductive film, method for producing the same, and joined structure using the same

a technology of anisotropic conductive film and conductive film, which is applied in the direction of conductors, contact material materials, conductors, etc., can solve the problems of difficult to maintain the aligned state of the conductive particles on the insulating adhesive layer, the loss of charge of the conductive particles, and the anisotropic conductive film. achieve the effect of high capturing rate of conductive particles, excellent conduction reliability, and high conductive particle capture ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Anisotropic Conductive Film

[0108]To 9 parts by mass of Ni—Au plated resin particles (Micropearl AU, manufactured by Sekisui Chemical Co., Ltd., having a particle diameter of 4 μm, referred as “gold particles” hereinafter) as the conductive particles, toluene was added as the solvent, to thereby prepare 40% by mass conductive particle slurry. Hereinafter, this slurry is referred as “Liquid A”.

[0109]Next, 30 parts by mass of a fluid epoxy resin (bisphenol A epoxy resin) (EP828, manufactured by Japan Epoxy Resins Co., Ltd.), 30 parts by mass of a phenoxy resin (PKHH, manufactured by InChem Corporation), 1 part by mass of a silane coupling agent (A-187, manufactured by Nippon Unicar Company Limited), and 30 parts by mass of an imidazole-based latent curing agent (3941HP, manufactured by Asahi Kasei Chemicals Corporation) were mixed to thereby prepare a resin composition. To the resin composition, toluene was added as the solvent to thereby prepare 10% by mass toluene solu...

example 2

Preparation of Anisotropic Conductive Film

[0117]An anisotropic conductive film of Example 2 was formed in the same manner as in Example 1, provided that the compositions of the slurry of the conductive particles (Liquid A) and the toluene solution of the resin (Liquid B) of Example 1 were respectively changed to the following compositions.

[0118]To 10 parts by mass of Ni—Au plated resin particles (Micropearl AU, manufactured by Sekisui Chemical Co., Ltd., having a particle diameter of 4 μm) as the conductive particles, toluene was added as the solvent, to thereby prepare a 40% by mass conductive particle slurry.

[0119]Liquid B was prepared as follow. At first, 35 parts by mass of a fluid epoxy resin (bisphenol A epoxy resin) (3002A, manufactured by Kyoeisha Chemical Co., Ltd.), 45 parts by mass of a phenoxy resin (PKHH, manufactured by InChem Corporation), 2 parts by mass of a silane coupling agent (A-172, manufactured by Nippon Unicar Company Limited), and 8 parts by mass of an radic...

example 3

[0150]To Ni—Au plated resin particles (Micropearl AU, manufactured by Sekisui Chemical Co., Ltd., having a particle diameter of 4 μm, referred as “gold particles” hereinafter) as the conductive particles, toluene was added as the solvent, to thereby prepare 100 g of 30% by mass conductive particle slurry. Hereinafter, this slurry is referred as “Liquid A”.

[0151]Next, to a bisphenol A epoxy resin (fluid epoxy resin) (EP828, manufactured by Japan Epoxy Resins Co., Ltd.), toluene was added as the solvent to thereby prepare 100 g of 20% by mass toluene solution of the resin. Hereinafter, this toluene solution is referred as “Liquid B”.

[0152]As a subject (the processing surface) for which conductive particles were aligned, a film (a PET layer) formed of polyethylene terephthalate (PET) was provided.

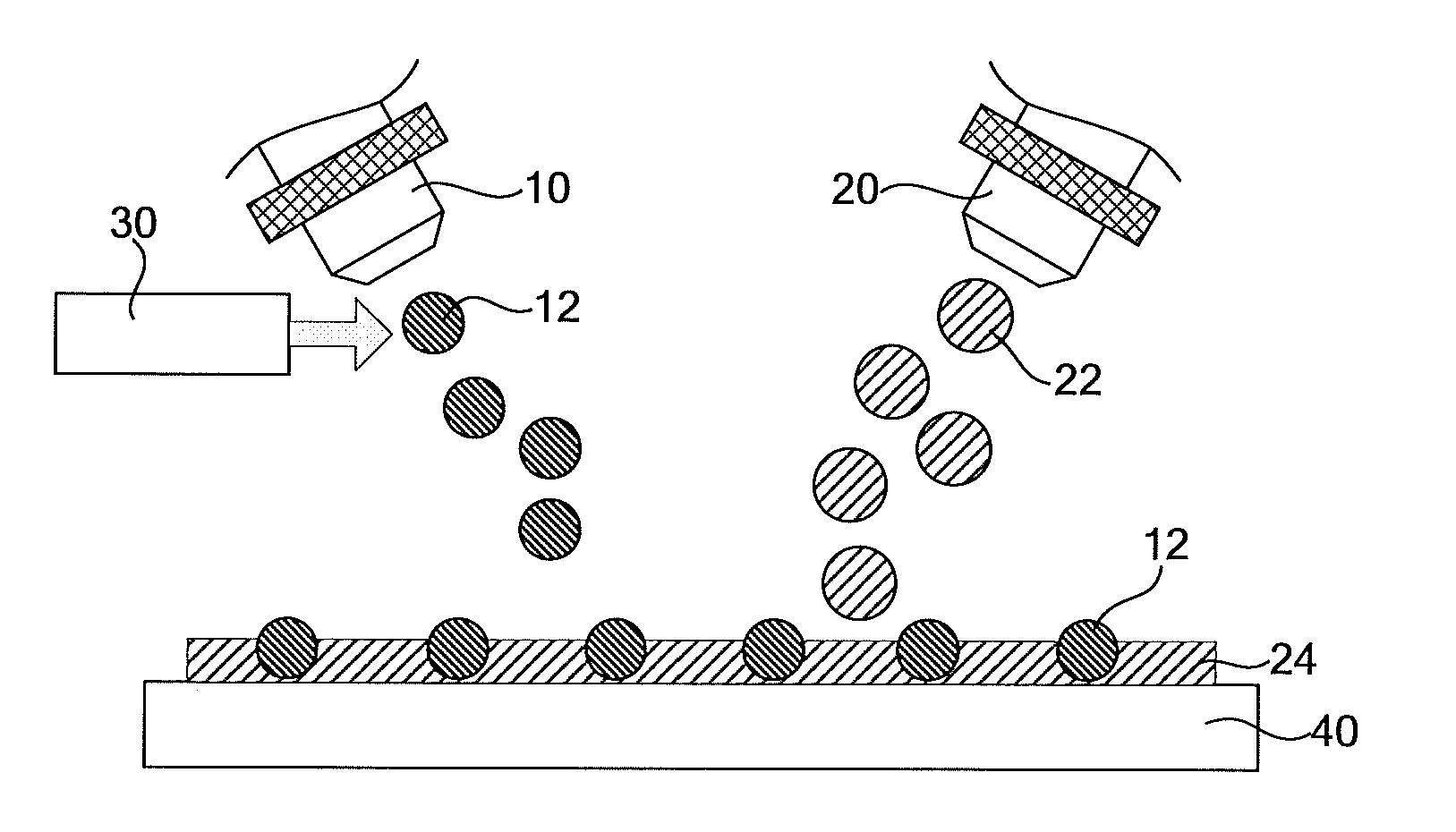

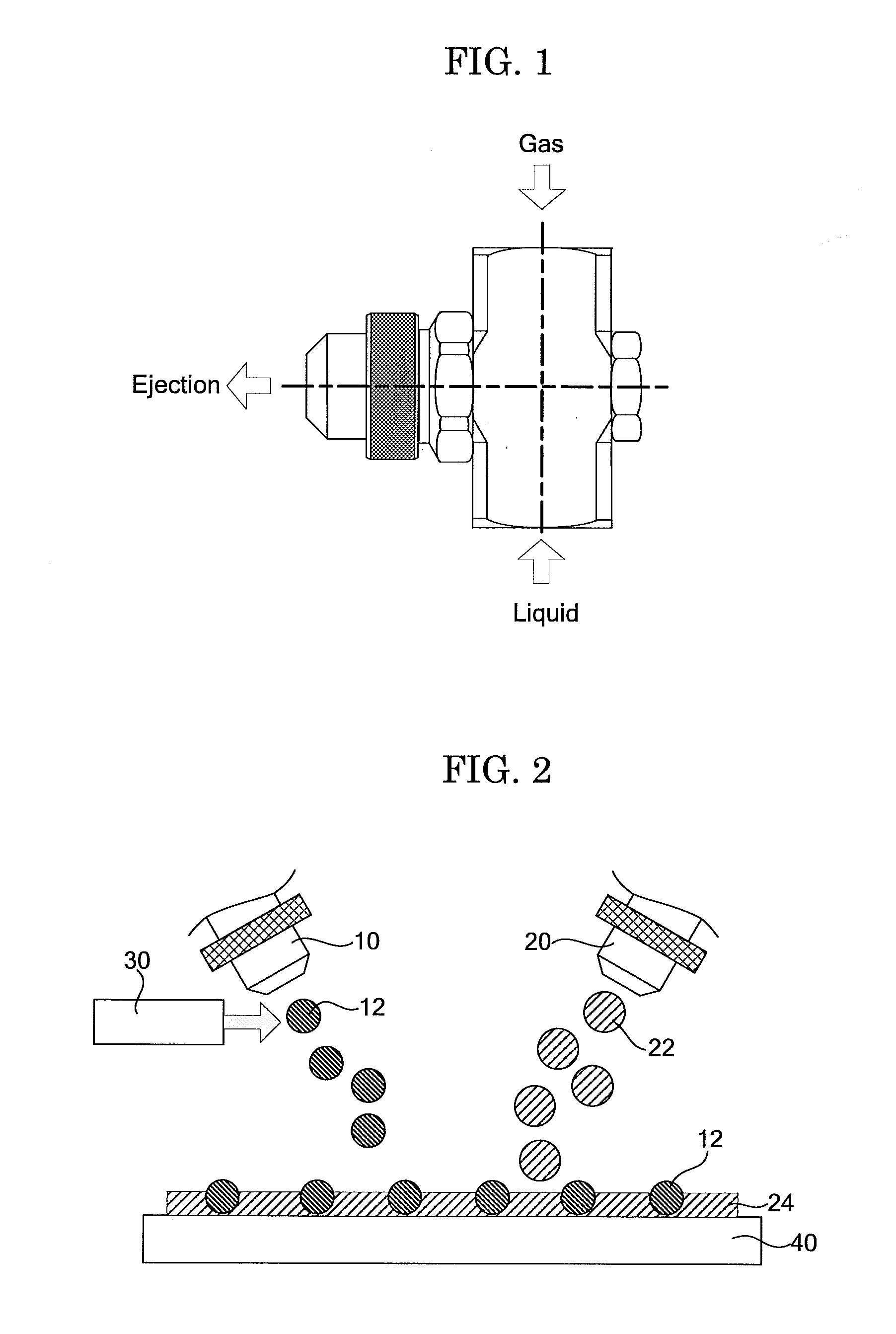

[0153]Next, two spraying devices to each of which a two-fluid nozzle (a two-fluid spray nozzle 1 / 4JAUCO, manufactured by Spraying Systems Co.) shown in FIG. 1 was connected were prepared for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com