Processes for Producing Fermentation Products

a technology of fermentation products and process steps, applied in the direction of fermentation, biofuels, etc., can solve the problems of difficult synthetic production of commercial products, too costly production of fermentation products such as ethanol, from such plant materials, and difficult production of commercial products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Fermentation of Liquefied Corn Mash With Trehalase

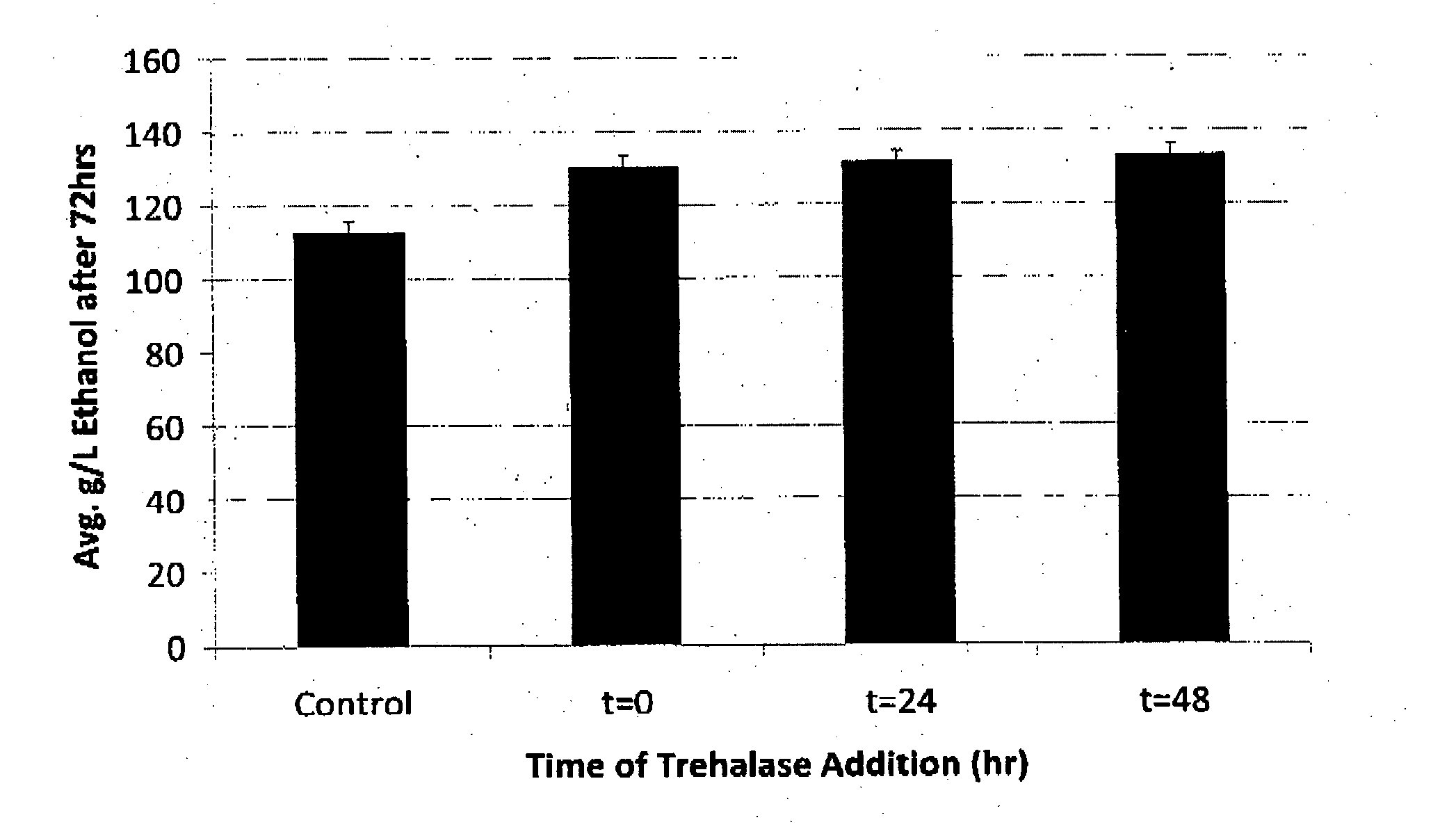

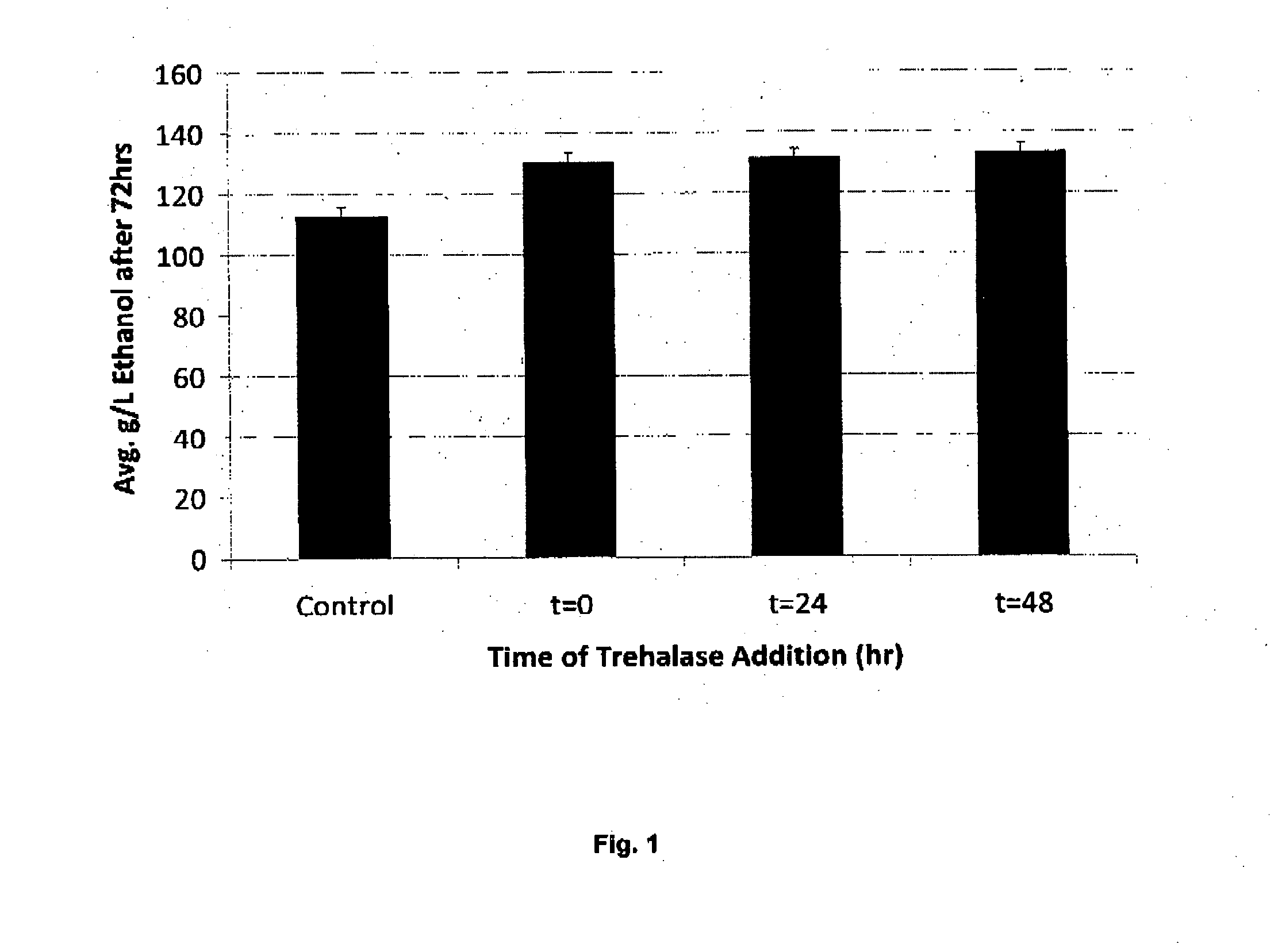

[0357]A fermentation study was conducted in which trehalase from Sigma Chemical Company (cat. #T8778) was added at 0.10 g protein / L (40 Sigma Units) to a conventional liquefied corn mash from Adkins Energy (30.2 wt % DS). Fermentation was carried out at 32° C. for 70 hours. 500 ppm of urea and 3 ppm of penicillin were added (final concentrations in 5.0 g mash samples, samples fermented in 15 mL conical plastic centrifuge tubes with small hole drilled at top for CO2 release). Glucoamylase blend AG was added at time 0 at a dose of 0.37 AGU / g DS. RED STAR™ yeast was pitched into the fermentation at time 0 at an initial cell density of 30,000,000 cells / mL. The quantity of ethanol was measured by HPLC

[0358]The results of the study are displayed in FIG. 1 showing that addition of trehalase after 0, 24 and 48 hours, respectively, in a 70 hour fermentation leads to increased ethanol yield.

example 2

Trehalase Treatment

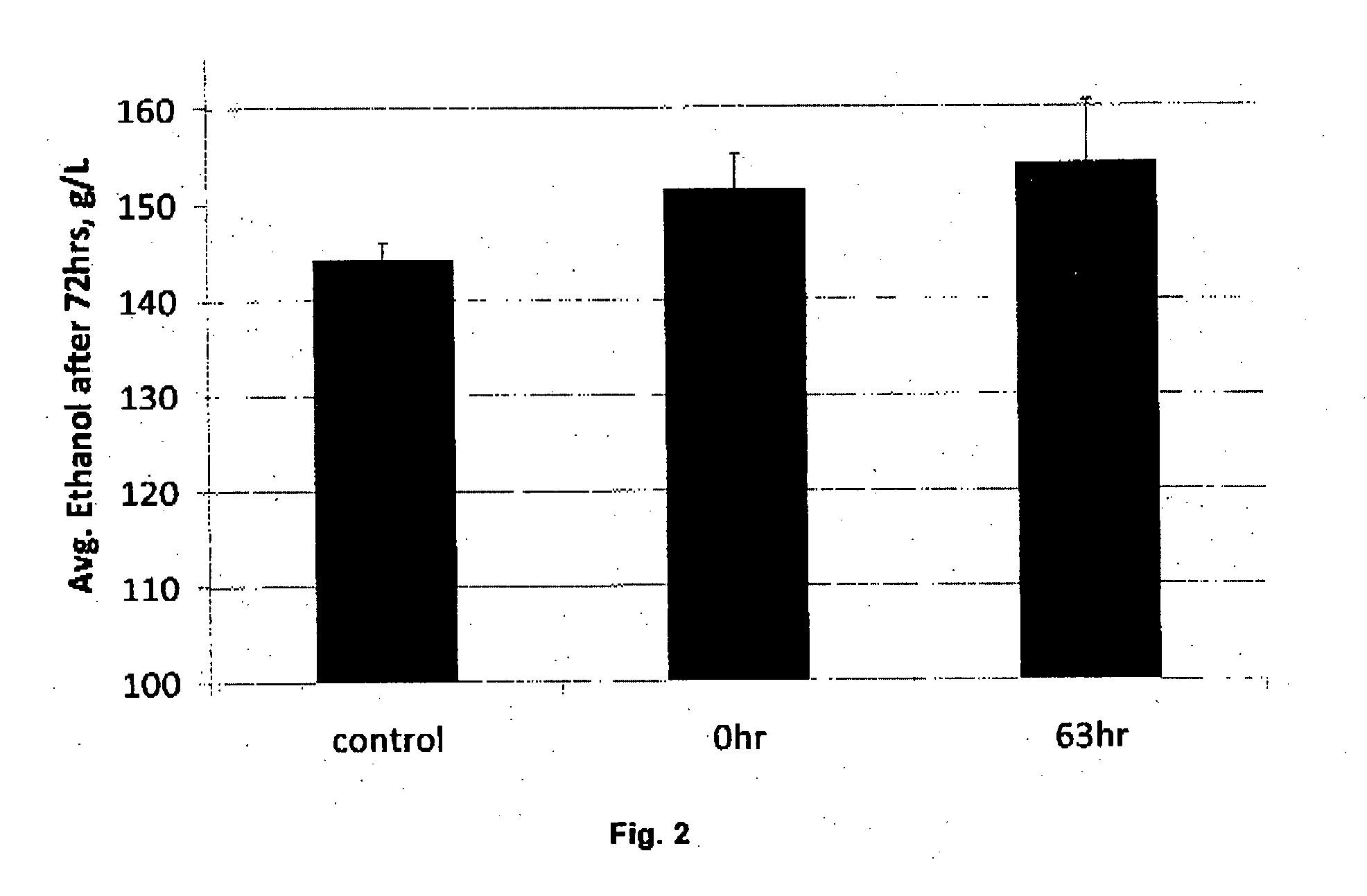

[0359]A fermentation study was carried out as described in Examples 1, except that conventional liquefied corn mash was from Verasun Fort Dodge with 32 wt % DS and trehalase was added at time 0 and after 63 hours.

[0360]The results of the study are displayed in FIG. 2 showing that addition of trehalase after 0 and 63 hours, respectively, in a 70 hour fermentation leads to increased ethanol yield.

[0361]FIG. 3 shows a chromatogram from an ion chromatographic system which illustrates the reduction in the peak for trehalose observed upon addition of trehalase to the fermentation of the corn mash. The top curve is for the mash treated with trehalase, and the bottom curve is for the untreated mash.

example 3

Fermentation of Backset With Trehalase

[0362]A fermentation study was carried out as described in Examples 1, except that trehalase was added at 0.20 g protein / L (80 Sigma Units) to samples of backset from Verasun Energy (6.7 wt. % DS) and Hawkeye Fairbanks (5.8 wt. % DS), respectively. Trehalase was added at either the start of the fermentation or after 63 hours. The quantity of ethanol was measured by HPLC. The results of the study are displayed in FIG. 4 showing that addition of trehalase is more beneficial to the ethanol yield if added at the start of the fermentation compared to after 63 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com