Process and Device for Obtaining Liquid Nitrogen by Low Temperature Air Fractionation

a technology of air fractionation and process, which is applied in the direction of refrigeration and liquifaction, lighting and heating apparatus, solidification, etc., can solve the problems of low separation efficiency, low efficiency of system, and high preliminary liquefaction of air introduced into the distillation column system, so as to achieve low energy consumption and use particularly efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

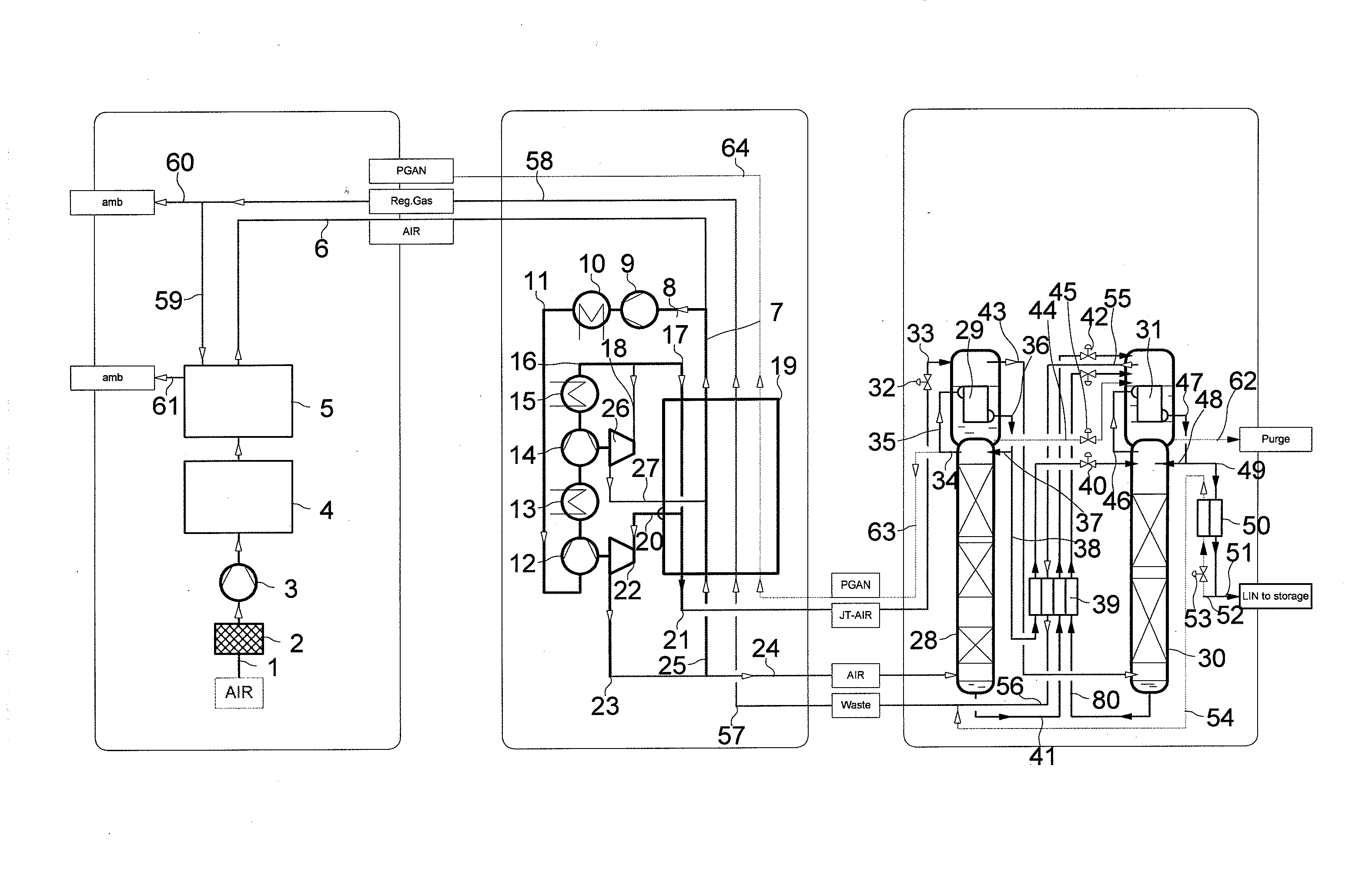

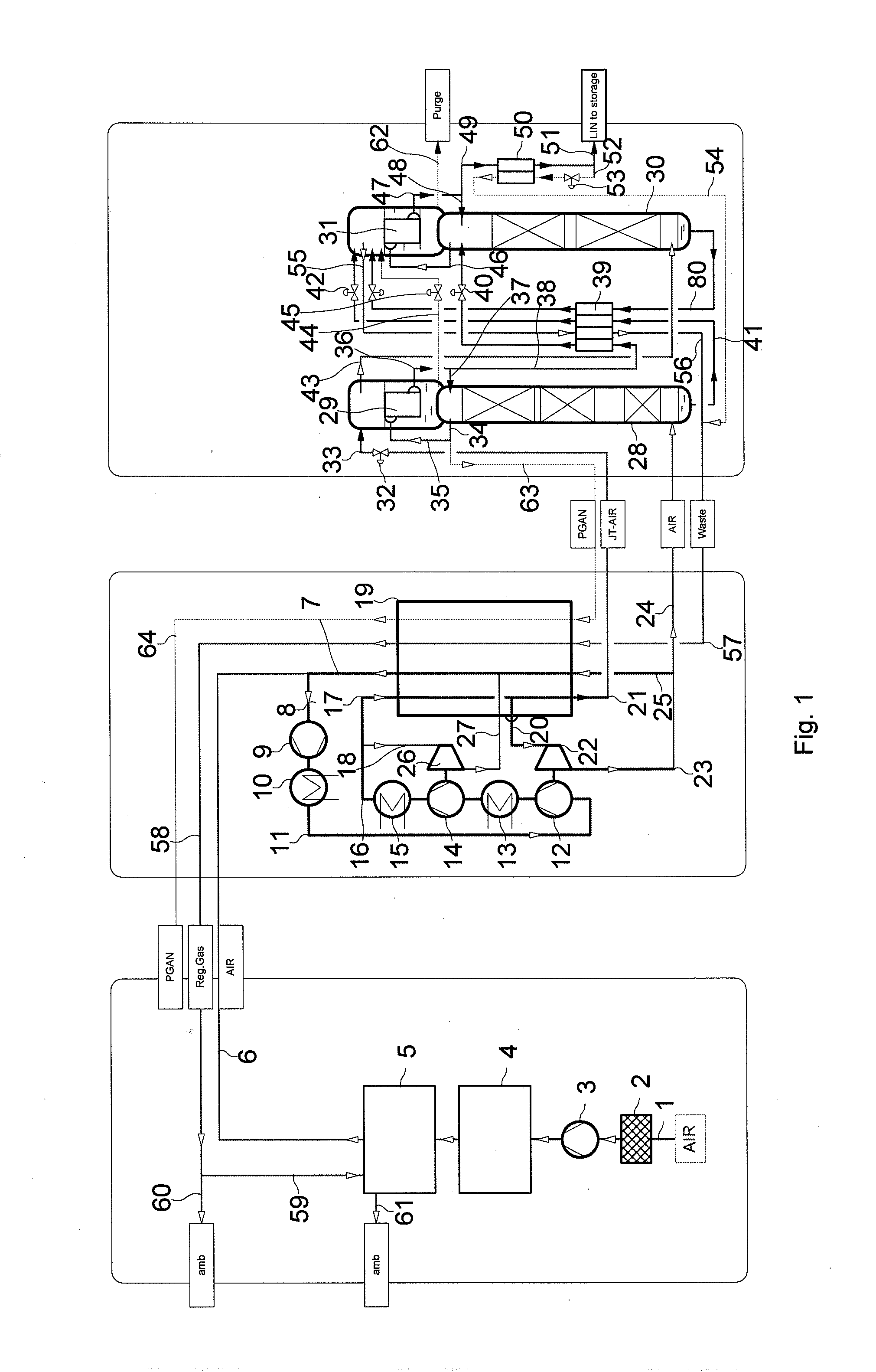

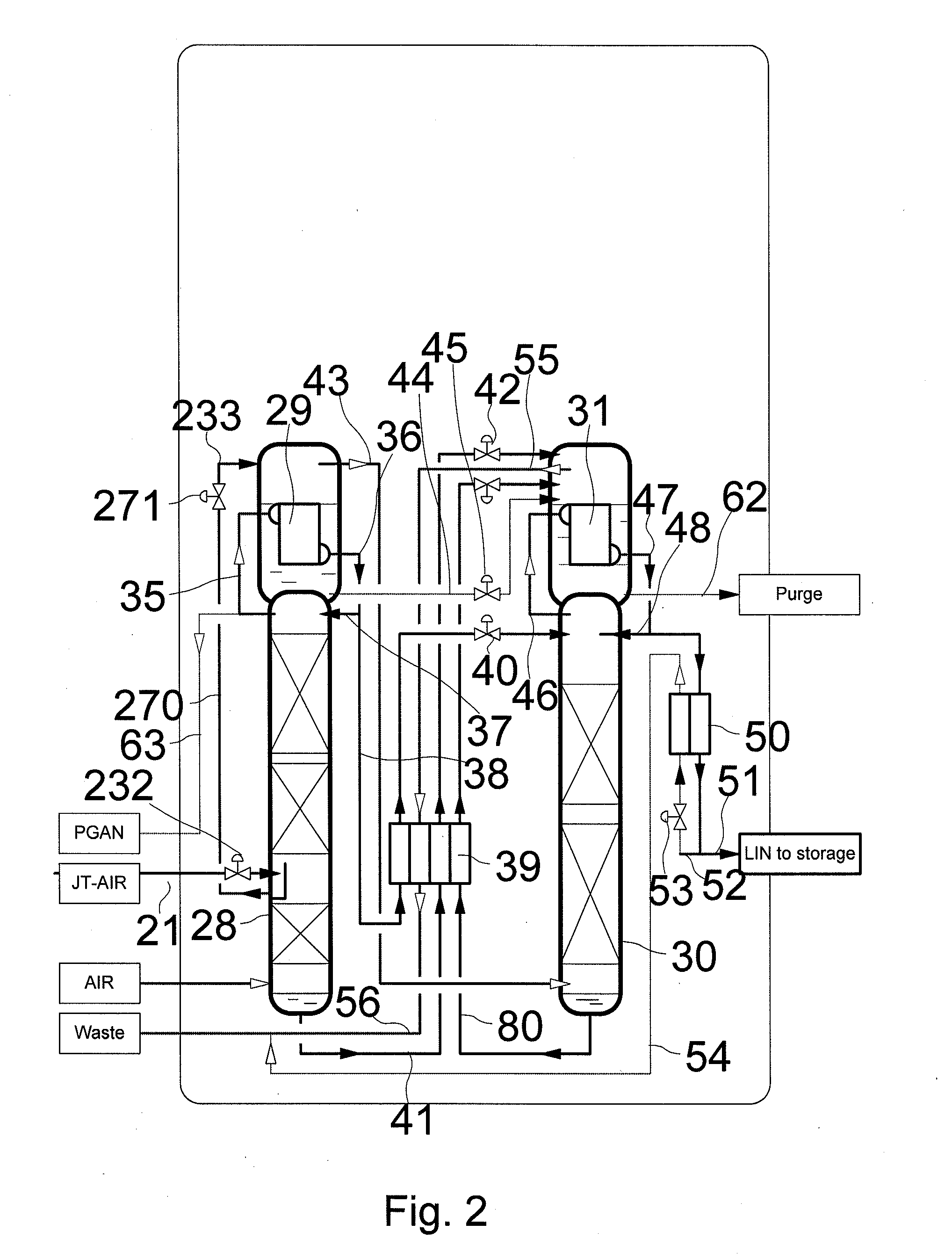

[0034]FIG. 1 is subdivided by three rectangles drawn in broken lines into the process parts pretreatment of air, cold system and distillation column system for nitrogen-oxygen separation (from left to right).

[0035]Incoming air 1 is fed via a filter 2 to a main air compressor 3 and compressed there to a first pressure of 5.5 to 7.0 bar and in a precooling appliance 4 is cooled back to about ambient temperature, for example, by indirect heat exchange in a heat exchanger or by direct heat exchange in a direct contact cooler.

[0036]The precooled air is purified at the first pressure in a purification appliance 5 which contains molecular sieve adsorbers. The purified air 6 (AIR) is fed to the cold system which serves for cooling the feed air and for generating liquefaction cold. There, the purified feed air 6 is first at least in part mixed with a return air stream 7 to give a circuit stream 8. The circuit stream 8 is further compressed to an intermediate pressure of 30 to 40 bar in a cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com