Method and device for electrostatic desalter optimization for enhanced metal and amine removal from crude oil

a technology of enhanced metal and amine removal, applied in the direction of solvent extraction, selective extraction of work pitch/asphalt/bitumen, separation process, etc., can solve the problems of increasing the profit of oil desalting, increasing the rate of electrical power consumption, and increasing the conductivity exponentially

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

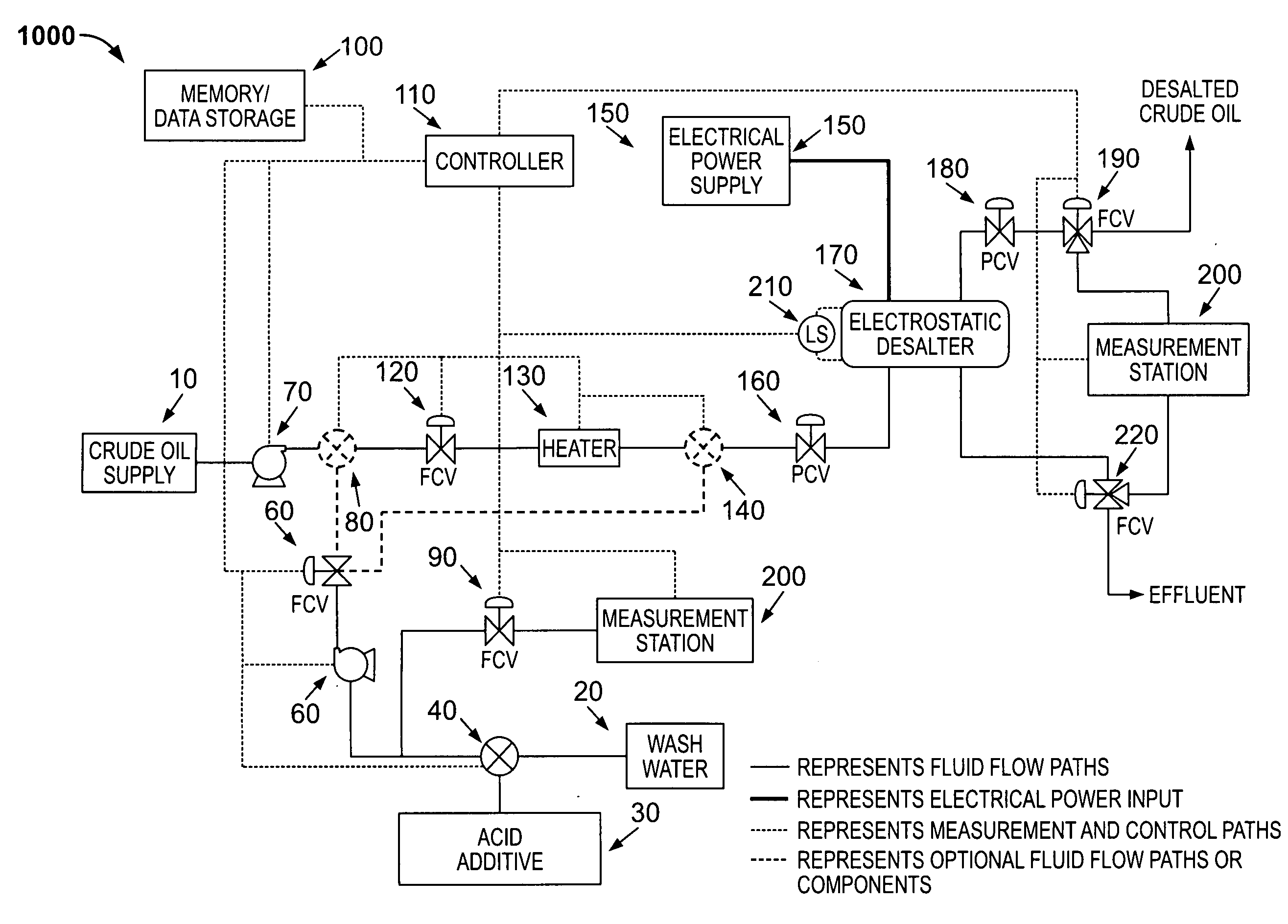

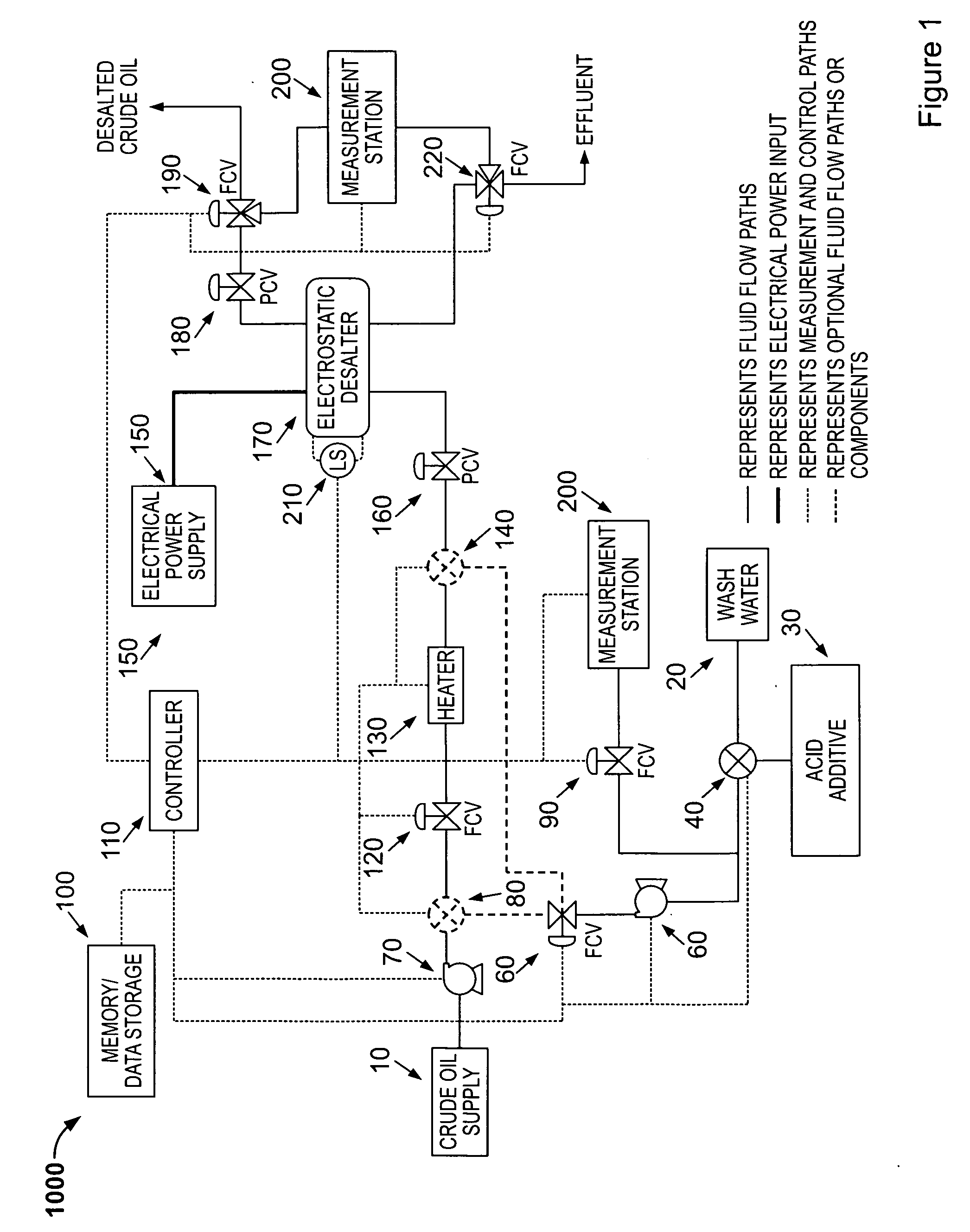

[0016]FIG. 1 shows a diagram of a single stage crude oil electrostatic desalting mechanism 1000 of the present invention.

[0017]The desalting mechanism 1000 of the present invention includes a crude oil supply 10 for storing crude oil. The crude oil supply 10 is connected to a controllable pump 70 which is connected to an optional controllable fluid mixer 80. The optional controllable fluid mixer 80 allows an emulsion of crude oil 10, wash water 20, and acid additive 30 to be created prior to heating based upon the specific characteristics of the crude oil supply 10 to be desalted. The optional controllable fluid mixer 80, if necessary to process the crude oil supply 10, is controlled by the controller 110 to create and maintain the proper emulsion mix of crude oil 10, wash water 20, and acid additive 30.

[0018]Following either the controllable pump 70 or the optional controllable fluid mixer 80 is a controllable flow control valve (FCV) 120. The controllable flow control valve 120 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water-soluble | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com