Preparation of setting slurries

a technology of setting slurries and slurries, which is applied in the field of preparation of slurries, can solve the problems of increasing the waiting time, no satisfactory technology, and premature setting of cement can be hugely expensive to rectify, and achieve the effect of accurate measurement and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

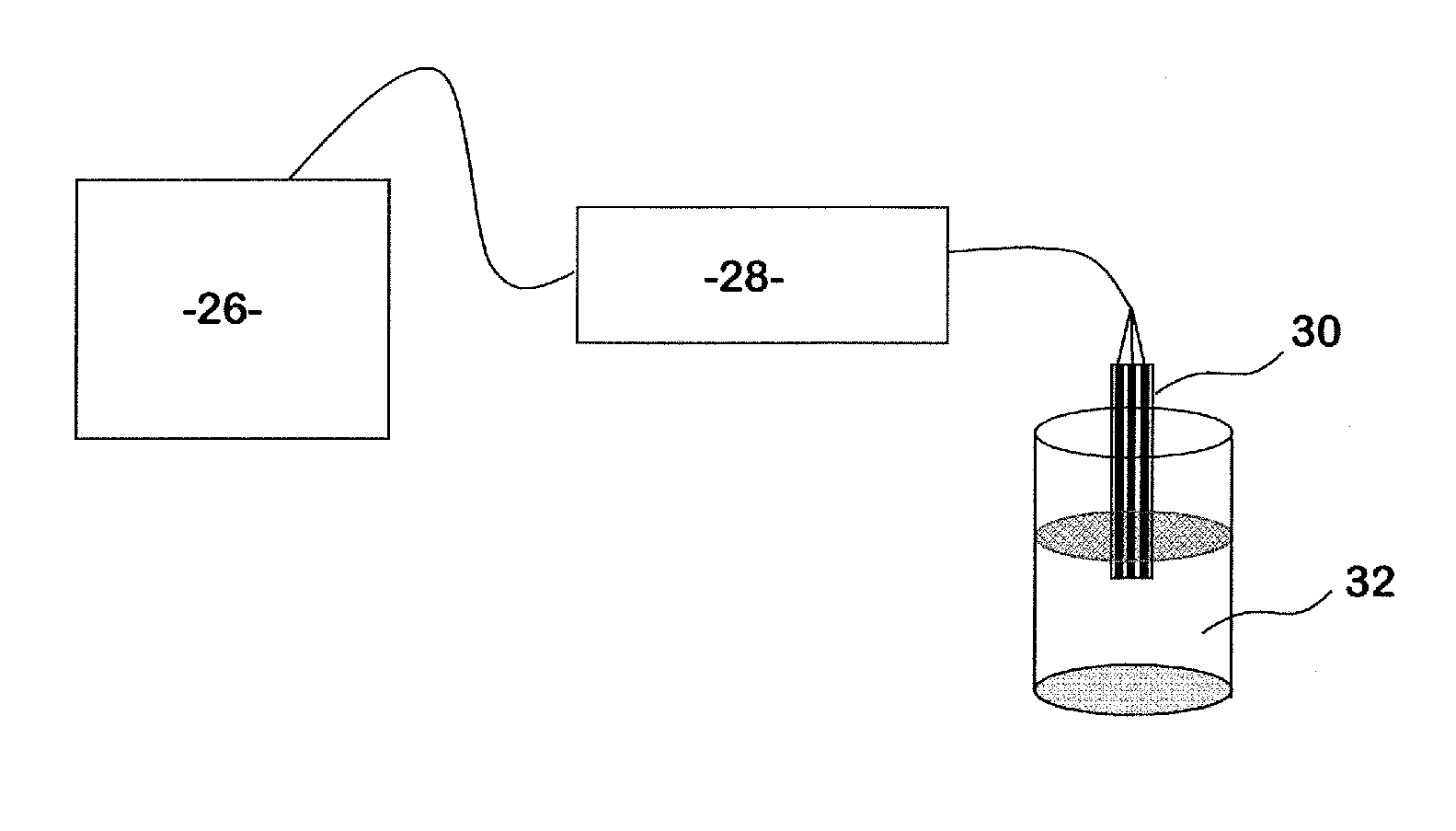

[0038]To demonstrate suitable electrochemistry, square wave voltammetry was carried out on a solution simulating mix-water containing a conventional retarder sodium pentaborate.

[0039]In this example, a glassy carbon working electrode was used with a standard calomel reference electrode. Voltammetry was carried out using a potentiostat from Eco Chemie BV, Utrecht, Netherlands.

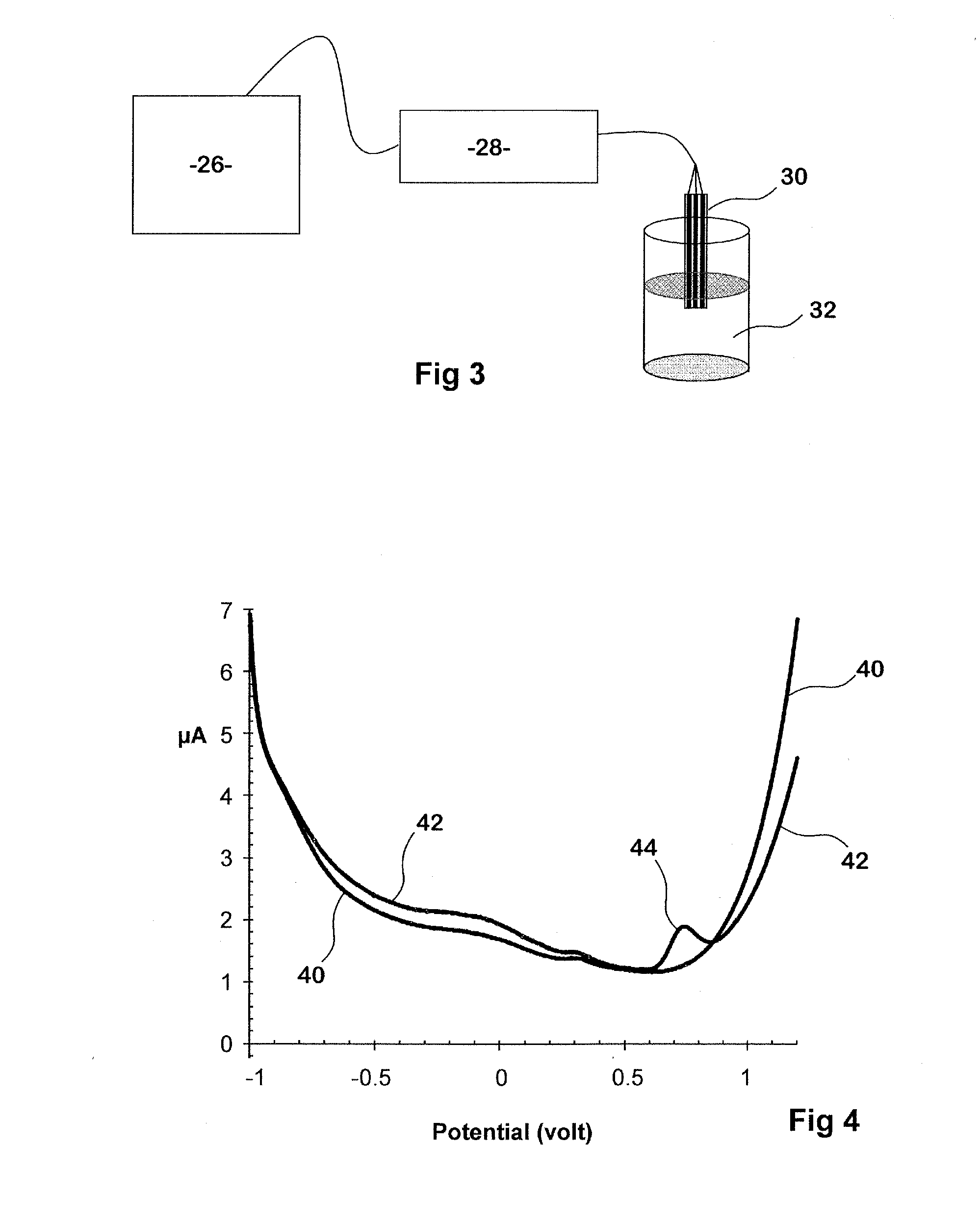

[0040]The results obtained are shown in FIG. 4 where curve 40 is the response when no xanthine was added. Curve 42 is the response when xanthine was added to the solution at a concentration of 40 μM. In the absence of xanthine no distinct redox active waves were observed in the electrochemical potential range scanned across. The lack of electrochemical activity in the pentaborate solution provided a background response and is important when using redox active tracers to detect the cement additive. Upon the addition of xanthine to the solution, a redox peak 44 emerges at ca. +0.75 V (vs. saturated calomel electro...

example 2

[0042]Square wave voltammetry was also carried out on solutions containing a mixture of calcium glucoheptonate (retarder), and polynapthalene sulphonate (dispersant). Voltammetry was carried out using a glassy carbon electrode. The tracer was t-butylferrocene sulfonate. The results are shown in FIG. 5.

[0043]Curve 50, obtained in the absence of t-butylferrocene sulfonate, shows no redox waves. By contrast, in curve 52, following addition of t-butylferrocene sulfonate to the solution a redox peak 54 emerges at +0.35 V (vs. SCE), consistent with a 1 electron oxidation of the ferrocene species to the ferricenium ion. The well defined nature of the peak enables such a species to be used as a tracer species.

example 3

[0044]An experiment was carried out to demonstrate the quantitative detection of ascorbic acid as a tracer in a cement retarder stock solution. Voltammetry in this experiment was carried out using a glassy carbon working electrode with a standard calomel reference electrode.

[0045]A sample of a simulated mix-water fluid was prepared that comprised a typical concentration of retarder (and associated chemical tracer) after dilution from a stock solution at the rig-site. The concentration of ascorbic acid in this simulated mix-water was 0.29 mM. A voltammetric linear scan was performed at a scan rate of 0.1 volt per second and the resulting plot of current against applied potential is shown as curve 56 in FIG. 6. It is the characteristic Faradaic signal associated with the oxidation of ascorbic acid. Curve 58 is a base line curve obtained with a similar solution omitting the ascorbic acid.

[0046]A 100 mM standard solution of ascorbic acid was prepared in deionised water., 80 uL aliquots ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Electrochemical properties | aaaaa | aaaaa |

| aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com