Method of configuring an LED driver, LED driver, LED assembly and method of controlling an LED assembly

a technology of led fixtures and drivers, applied in the direction of electric discharge lamps, electric variable regulation, instruments, etc., can solve the problems of inconvenient installation, increased installation time, and increased cost, and achieves high efficiency, wealth of functionality, and easy adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

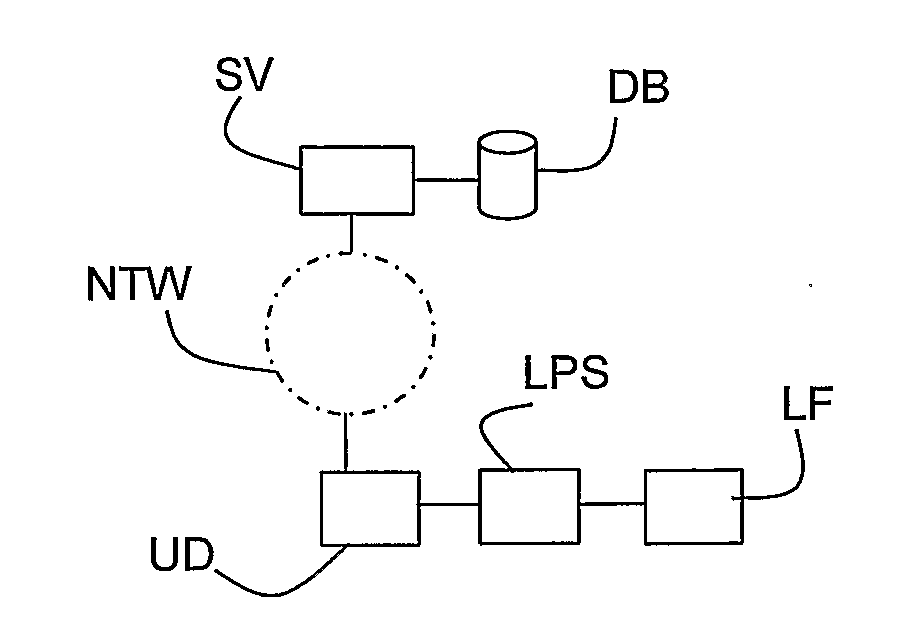

FIG. 1a depicts a database DB comprising configuration data. The data base is via a server SV (such as a web server or other network server) connected to a communication network NTW, such as the internet, a telecommunication network, a DMX communication bus, etc. The network is connected to a user communication device UD, such as a personal computer, notebook, (e.g. internet enabled) mobile telephone, etc to which an LED driver LPS may be connected. The LED driver is connected to an LED fixture LF to drive it. It is noted that the driving of the LED fixture may comprise providing electrical power to it and / or driving different groups of the LEDs of the LED fixture (e.g. different colors) according to e.g. a users needs. In order to configure the LED driver, the LED driver and / or the LED fixture are to be identified. This may take place in a variety of ways. An identification may for example be sent by the LED driver to the user device UD (either autonomously by the LED driver or upo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com