Apparatus and method for controlling moisture in the manufacture of glass fiber insulation

a technology of glass fiber insulation and apparatus, which is applied in the field of apparatus and method for controlling moisture in the manufacture of glass fiber insulation, can solve the problems of significant vaporization or “flashing” of the binder dispersion in the forming hood, release of binder solids or vaporized gasses into the atmosphere, and higher costs for increasing the use of binder, so as to achieve the effect of improving properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0164]Trials are conducted with varying amounts of water delivered to each of 10 fiberizing units. Ten set points or examples were designed according to Table 1, below. Liquids enter the forming hood as binder dispersion, as diluent for the binder dispersion, or as coolant water, the level of each being varied or held constant as shown in Table 1. Set points 1 and 9 were designed as controls with decreasing or profiled diluent and coolant water at lower average levels to represent the current state of the art. Other set points held various sources of water constant or flat at higher average levels, while others were varied or profiled from one unit to the next. Flows are given in liters per minute, LPM.

TABLE 1Flow* set points for liquids control (as designed**)Fiber.Unit:SetPtLiquids12345678910TOTAL1binder777777777770diluent3.83.83.53.12.31.71.200019.4coolant6.576.85.64.53.52.31.91.51.140.7total fl.17.317.817.315.713.812.210.58.98.58.1130.1bind + dil10.810.810.510.19.38.78.277789.4C...

example 2

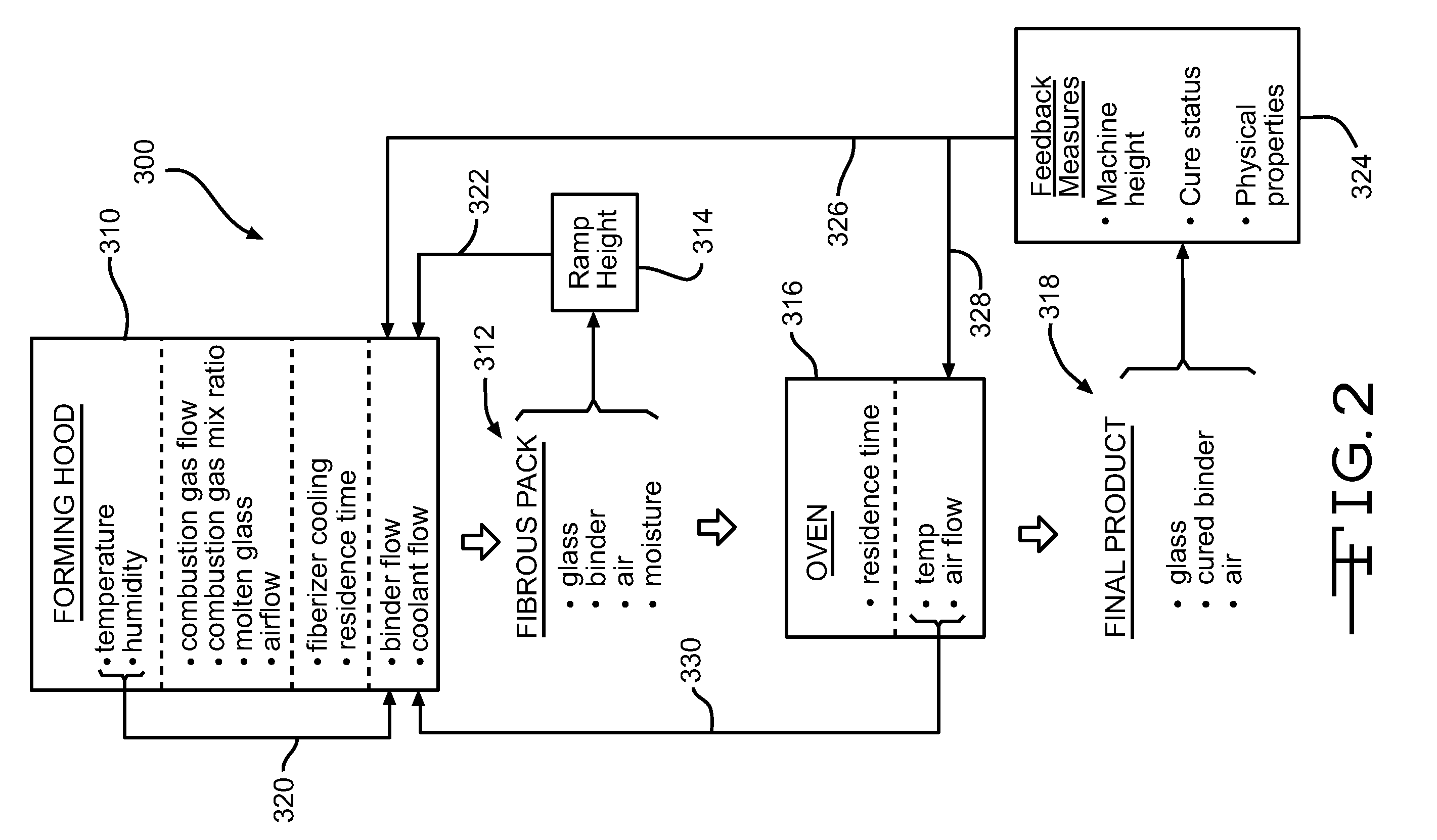

[0168]It was found that there were important relationships between several of the variables presented in Table 2. For example, it was discovered that the product properties of vertical weight distribution (VWD), also understood as the vertical density distribution, recovery measures and stiffness measures all improved dramatically with increased thickness of the pack as it exits the forming area and regains its uncompressed state, i.e. the “ramp height.”

[0169]Insulation batts having R-values of R12 and R20 were prepared in standard commercial operations. Quality control data was examined from these manufacturing runs to obtain values for EOL recovery and stiffness / sag at varying run times. Production data was mined to obtain ramp height and these ramp heights were paired to respective product properties for each selected run time. It was found that both recovery and stiffness / sag exhibited correlation to ramp height for both R12 and R20 batts. FIGS. 6B and 6C depict this relationshi...

example 3

[0171]Trials were also run to determine the impact of relative amounts of binder flow and coolant water flow. Set points called for binder flows of 4, 5, and 6 LPM, with binder concentrations being adjusted for equal delivery of binder chemical (same solids / same LOI content). Flow of coolant water was varied and ramp height was monitored. For each binder flow level (4, 5, or 6 LPM), the minimum and maximum ramp heights were about the same, roughly 250 mm for the minimum and 450 mm for the maximum. But at each different binder flow (4, 5, or 6 LPM) it took a different level of coolant flow to achieve the same ramp height levels. As expected, when the binder flow went down, the level of coolant flow had to be increased to achieve comparable ramp heights. Thus, ramp height is related to the total water provided to the forming hood.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com