High lubricity fuel reformulation to increase mileage and reduce emissions

a high lubricity, fuel technology, applied in the direction of fuel additives, liquid carbonaceous fuels, petroleum industry, etc., can solve the problems of significant diesel particulate matter, engine knock, engine knock, etc., to reduce combustion emissions, increase fuel economy, and reduce the fuel consumption of internal combustion engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

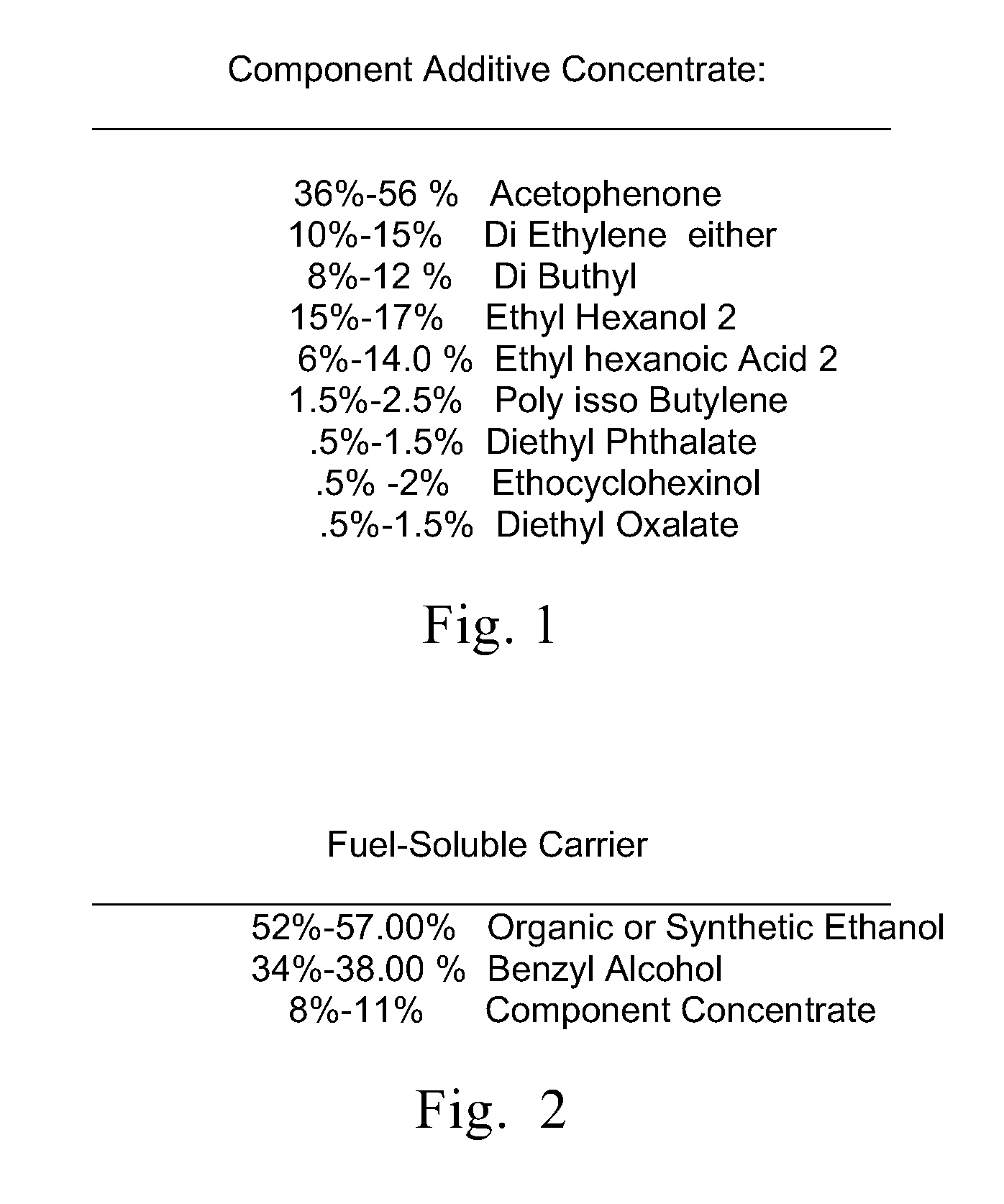

[0029]As shown in the figures and described herein, the additive composition can be provided as a concentrate which may be later diluted using a fuel-soluble carrier or can be mixed with the fuel-soluble carrier and provided in a pre-mixed manner where it is placed in the fuel tank of the internal combustion engine.

[0030]As shown in FIG. 1, the component additive consists of a plurality of components mixed in ranges to achieve the concentrate additive mixture. The concentrate additive mixture is then mixed with the fuel-soluble liquid carrier in a ratio of between 9-11 percent of the concentrate to the total volume of the mixed concentrate and liquid carrier. For example between 9-11 ounces of the additive concentrate in a total volume mixture of additive concentrate and liquid carrier of 100 ounces.

[0031]Currently a 10 percent mixture of component additive concentrate is a favored mode of the additive invention which is mixed with a sufficient amount of the liquid carrier component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| total volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com