Novel cracking catalytic compositions

a catalytic composition and composition technology, applied in the field of new cracking catalytic compositions, can solve the problems of loss of hydrocarbon materials, adverse effects on the composition of product mixes, and high conversion rates, and achieve the effects of maximizing conversion, minimizing aromatic formation, and maximizing the yield of lco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

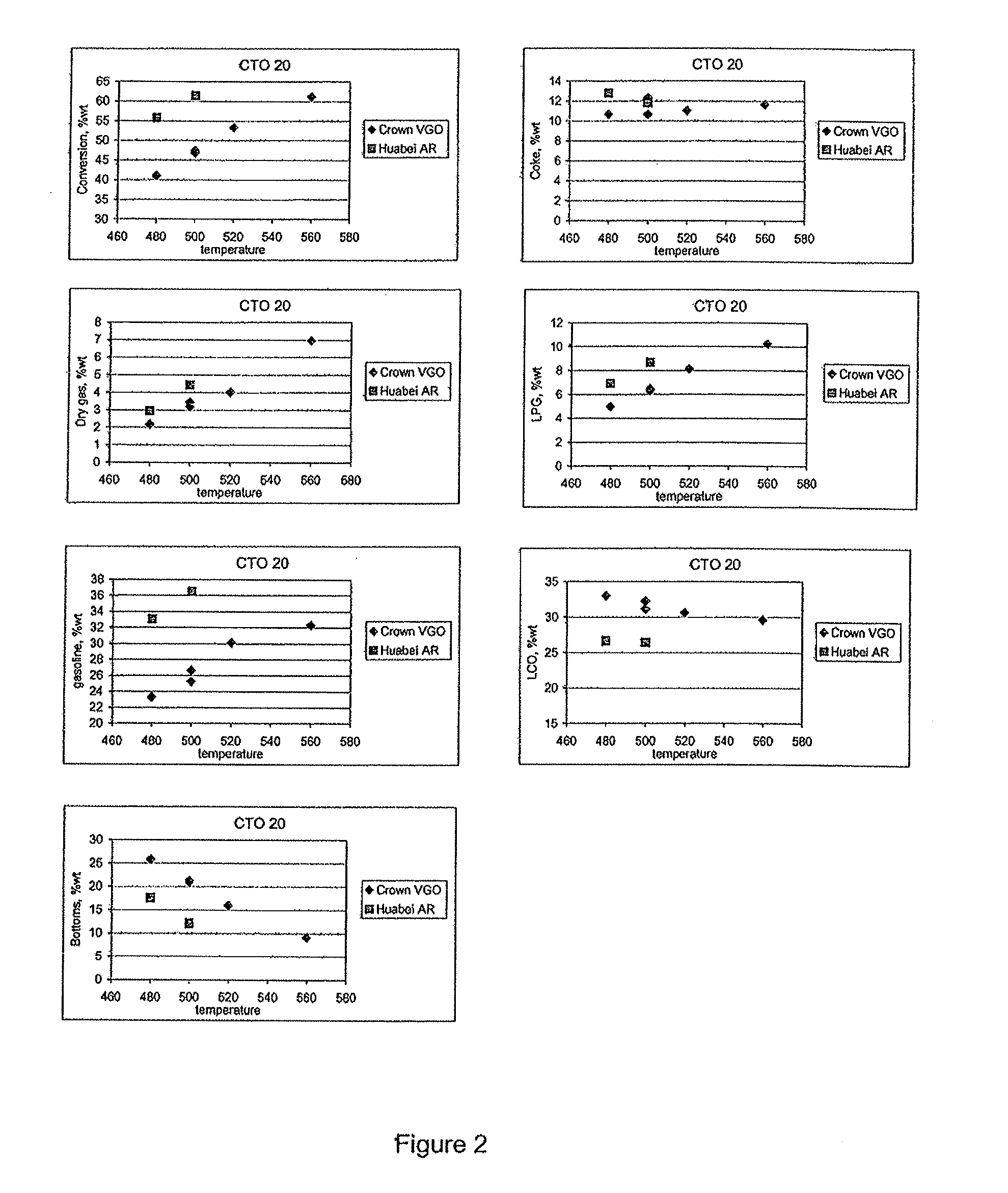

[0084]The commercial FCC catalyst, a sample of the clay material, and a sample of the hydrotalcite material were tested in the test reactor described above. The feed conversion rate was varied by varying the catalyst-to-oil (CTO) ratio. For each test run the reaction product was collected. The LCO fraction was analyzed for aromatics content. Standard LCO cutpoint of 221 to 350° C. was used. The results are summarized in Table 1.

TABLE 1FCCFCCClayHTCCatalystClayHTCCatalystBottoms yield,303030202020wt %LCO Aromatics584258 (*)604570Content, wt %(*) estimate

[0085]Both the clay material and the hydrotalcite material produced an LCO fraction with significantly lower aromatics content than that produced by the conventional FCC catalyst.

[0086]Decreasing the bottoms yield by increasing the CTO ratio dramatically increased the aromatics content of the LCO fraction in the case of the conventional FCC catalyst. For example the aromatics content of LCO increased from 70 wt % to above 90 wt % when...

example 2

[0088]Aluminum phosphate materials prepared as described above were modified by impregnation with La, Zn, and Zr, respectively. Their properties are summarized in Table 3.

TABLE 3SA (ma / g)M (wt %)Al (wt %)P (wt %)AlPOx31613283LaAlPOx15629237ZnAlPOx20013381ZrAilOx12631155SA is the specific surface area, as measured by the BET method.M is the amount of dopant metal.Al is the amount of aluminum.P is the amount of phosphorus.

[0089]As feedstock Crown VGO was used.

CHARACTERISTICS OF KUWAIT VGOSIMDIST° C.10 wt %32020 wt %35330 wt %37440 wt %39350 wt %41460 wt %43770 wt %45780 w1 %47690 wt %51295 wt %FBP561SATURATES, wt %62.4MONO-AROMATICS, wt %17.0Di-AROMATICS, wt %11.1DI+-AROMATICS / POLARS, wt %9.4SULFUR, ppm wt6400NITROGEN, ppm wt1153CCR, wt %0.14

[0090]A silica magnesia material was prepared according to example 1 of U.S. Pat. No. 2,901,440, with the exception that no HF was added before drying.

[0091]The catalyst materials were tested for their cracking activities, as described in Example ...

example 3

[0096]Hydrotalcite was prepared following the procedure described in U.S. Pat. No. 6,589,902. The Mg to Al ratio was 4:1. The hydrotalcite was calcined at 600° C. for one hour. As desired, metal ions were impregnated into the hydrotalcite by rehydrating the calcined hydrotalcite in an aqueous solution containing a salt of the desired metal.

[0097]A hydrotalcite-type Zn / Al mixed oxide was prepared using the same procedure, but replacing Mg with Zn.

[0098]The materials were tested in a microactivity tester (MAT) as described above. The contact temperature was 500° C. The results are summarized in Table 5.

TABLE 5ZnAlMo1ZnAIW2ZnAlV3MgAIFeW4MgAlFeV5MgAIV6MgAlMo7MgAlW8MgAlP9MgAlZr10CTO11.1911.1811.1811.1811.1911.1811.1811.211.1811.18Gasoline17.1517.6817.0816.4715.6218.4916.7119.1117.8720.77LCO30.0133.4930.2930.6128.9632.3630.6633.9932.7132.50Bottoms315633.3025.0626.1023.6726.2726.2126.5831.3829.99Coke15.819.1721.0220.4325.4016.2119.0112.439.957.26LCO / arom42.4742.8743.8738.8739.5741.1041.803...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| reaction temperature | aaaaa | aaaaa |

| reaction temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com