Method for the quantitative determination of soldering agent residues

a technology of soldering agent and quantitative determination, which is applied in the direction of manufacturing tools, soldering apparatus, other domestic objects, etc., can solve the problems of affecting the function and durability of other components, reducing the amount of flux materials used, and proving expensive and complicated, so as to achieve meaningful and reproducible measurement results, improve the measurement accuracy of methods, and improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

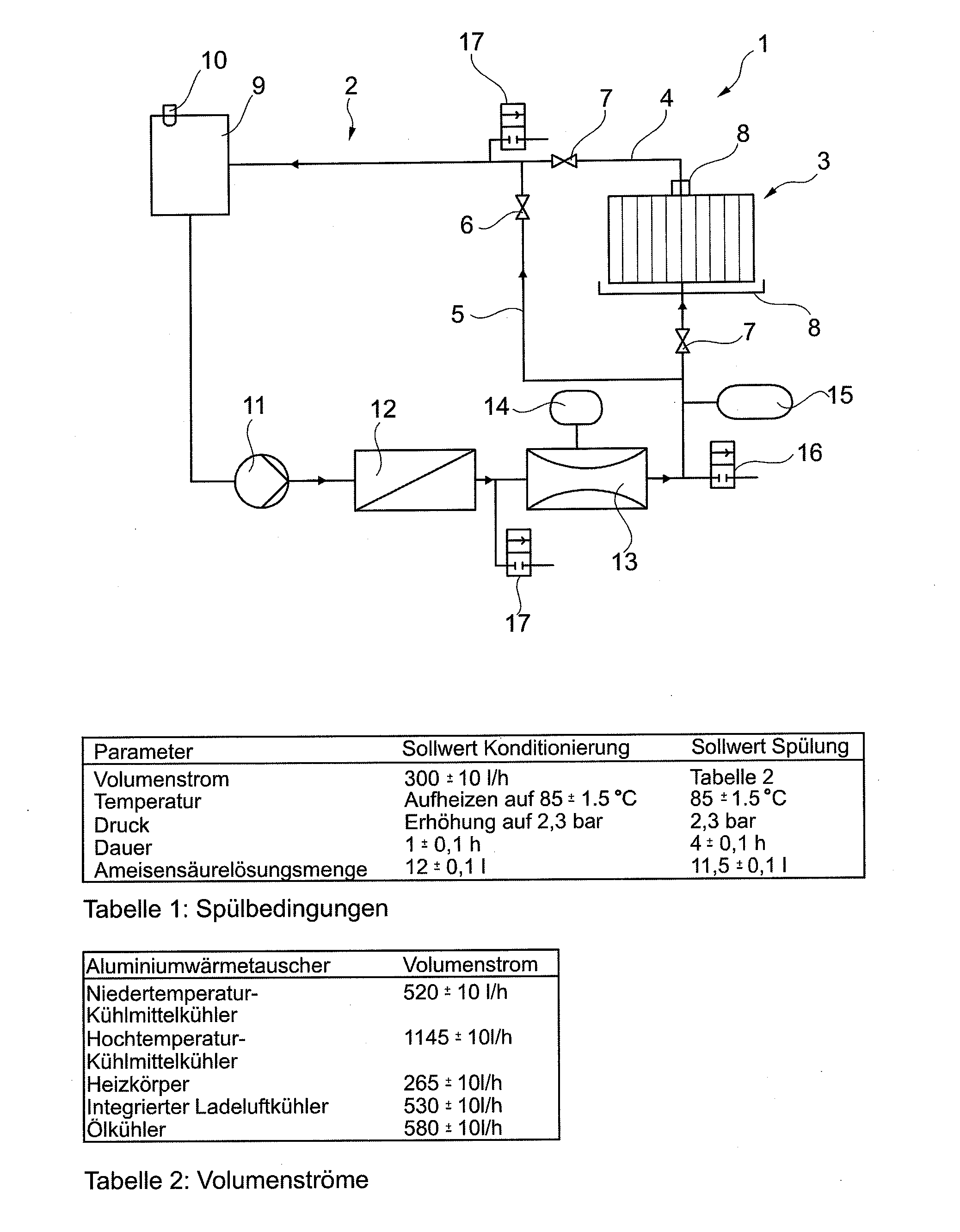

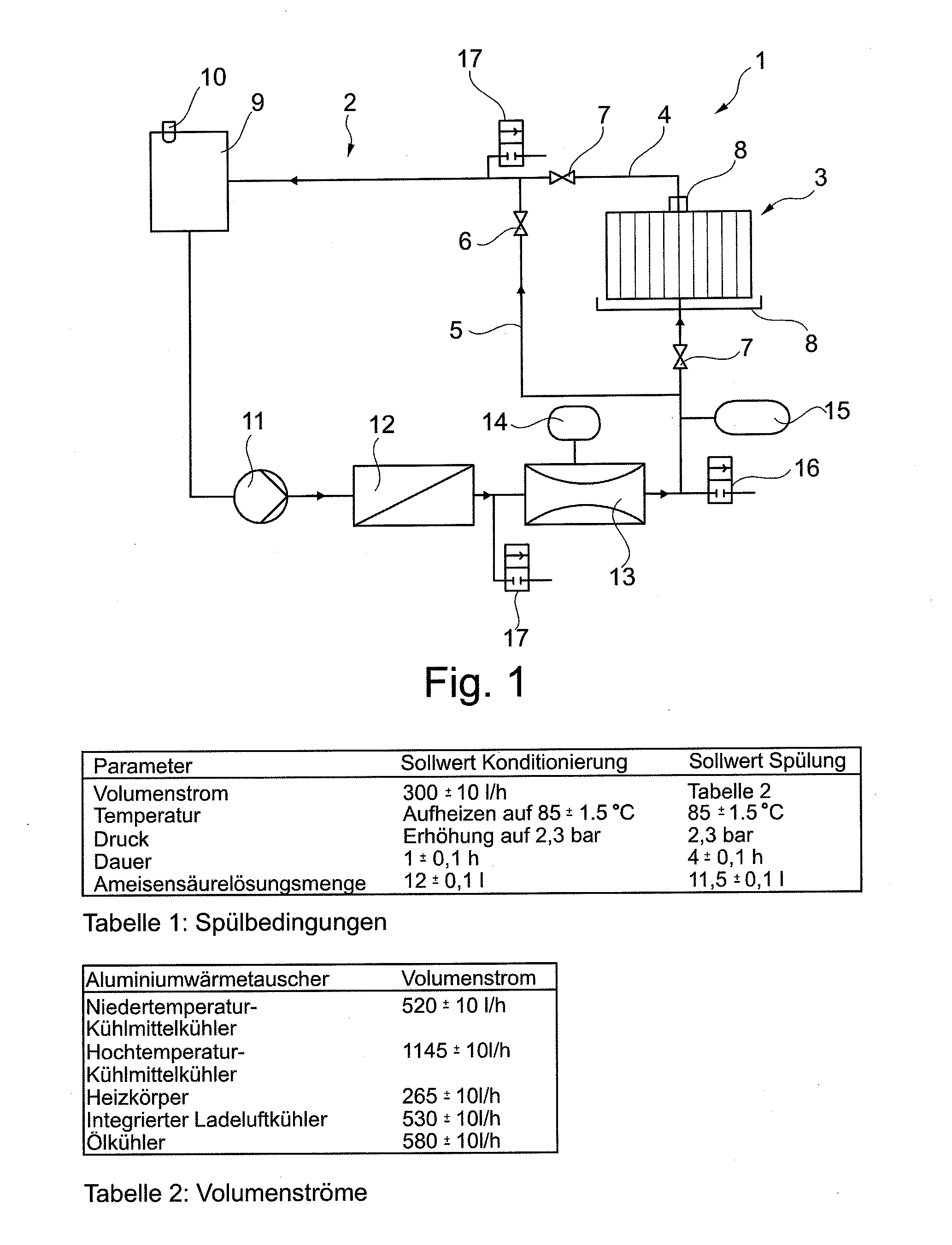

[0030]Shown in FIG. 1 in a schematic illustration is the circuit diagram of a first conceivable exemplary embodiment for a test system 1, with which the amount of the flux material remaining in a completed heat exchanger 3 to be tested (test piece) can be measured. Heat exchanger 3 was manufactured as a flat tube heat exchanger 3 known per se with lateral tube boxes, in which the flat tubes are inserted and then soldered to these. The actual soldering process in this case occurs, in a likewise known manner, by coating the flat tubes with solder and heating the fully assembled and prefixed heat exchanger 3 in a continuous heating furnace. To achieve an acceptable soldering result, the fully assembled heat exchanger 3 is dusted with flux material before heating, especially with a fluoroaluminate-containing flux material. After heat exchanger 3 cools, an (initially unknown) amount of excess flux material remains in the interior of heat exchanger 3. This residual amount of flux material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com