Metal-oxide films from small molecules for lithographic applications

a technology of metal-oxide films and lithographic applications, which is applied in the direction of photosensitive materials, instruments, photomechanical equipment, etc., can solve the problems of reducing the the inability to achieve sufficient lithographic performance for high-volume manufacturing, and the inability to reduce the thickness of the photoresist. the effect of reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

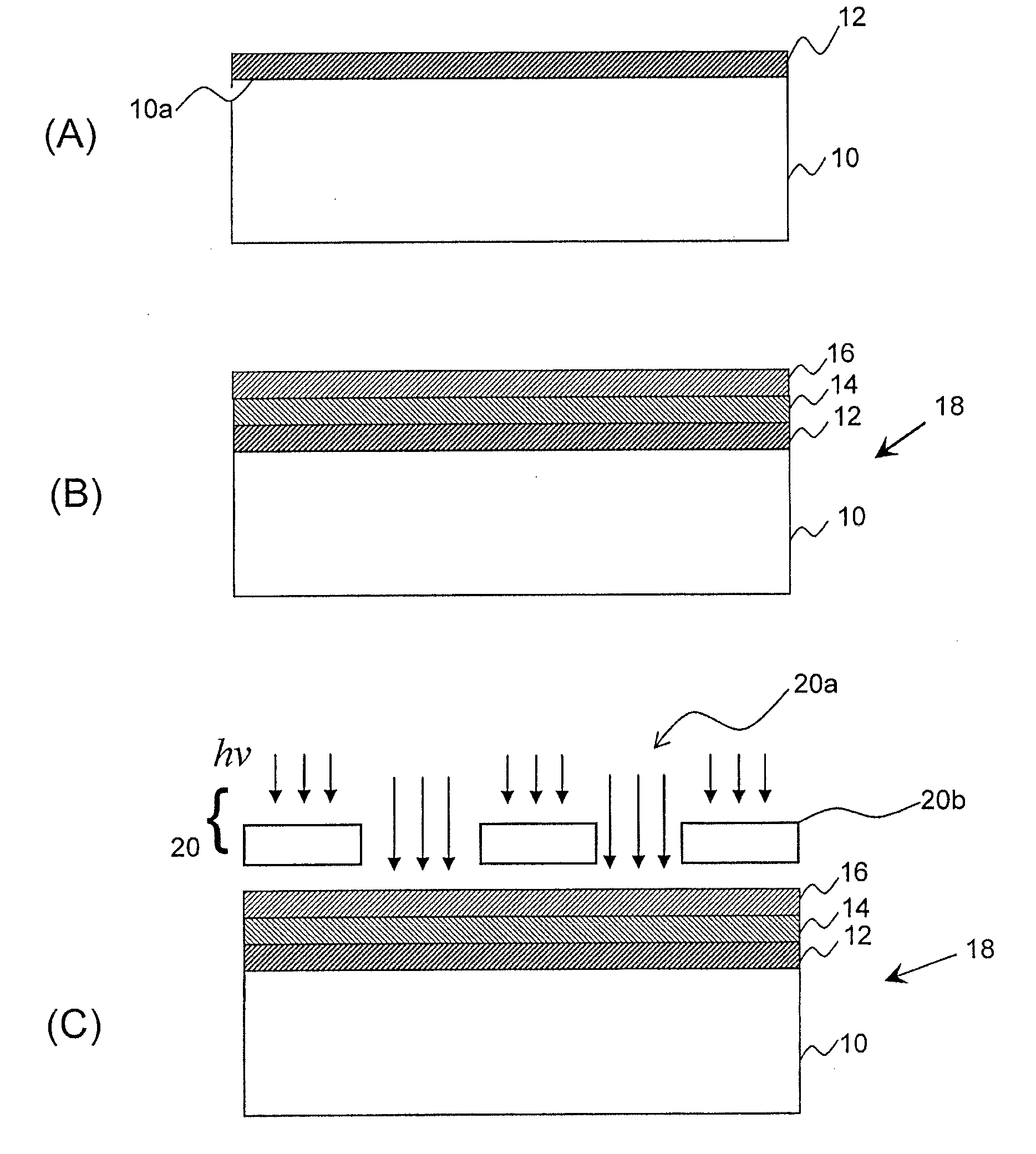

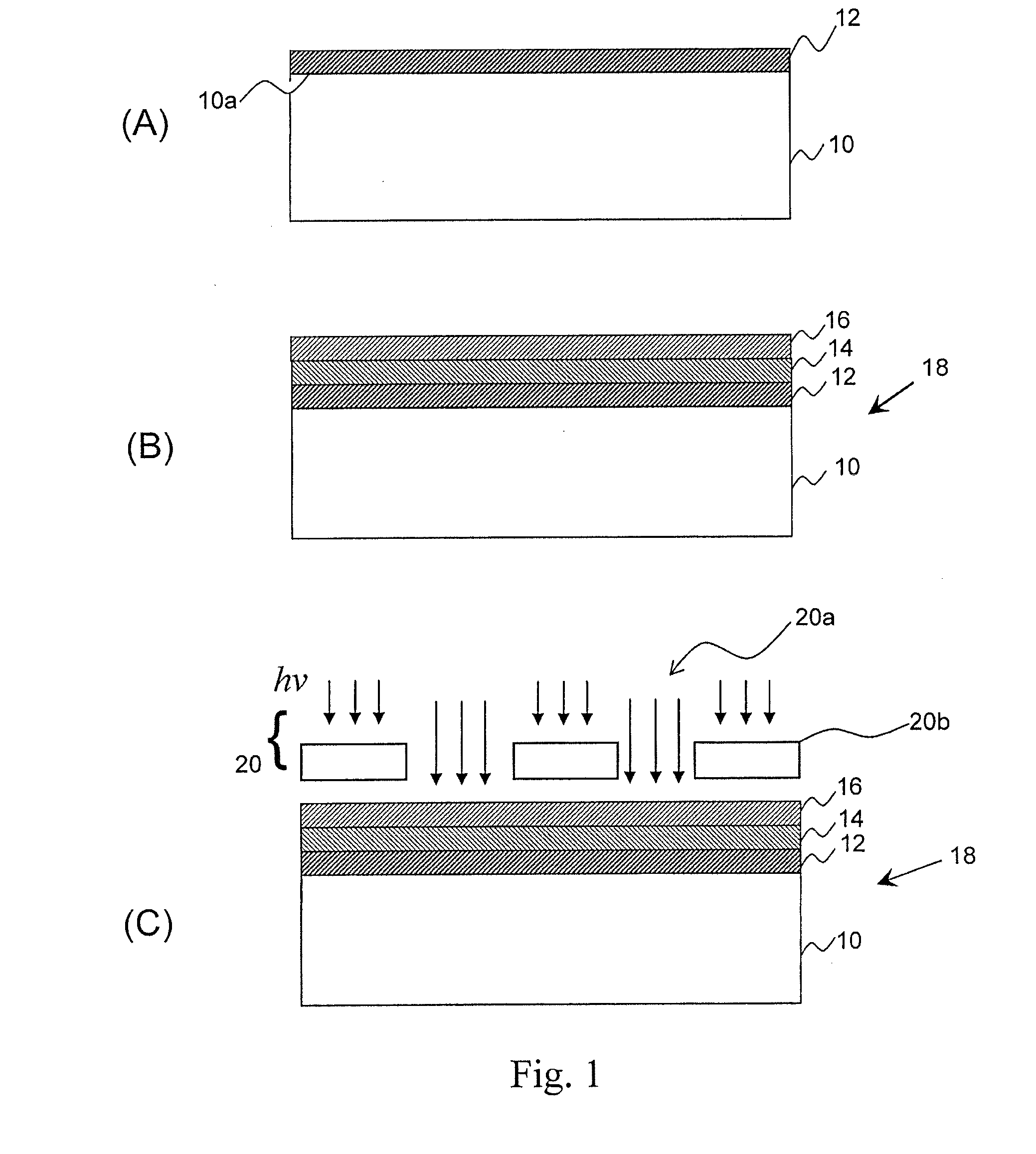

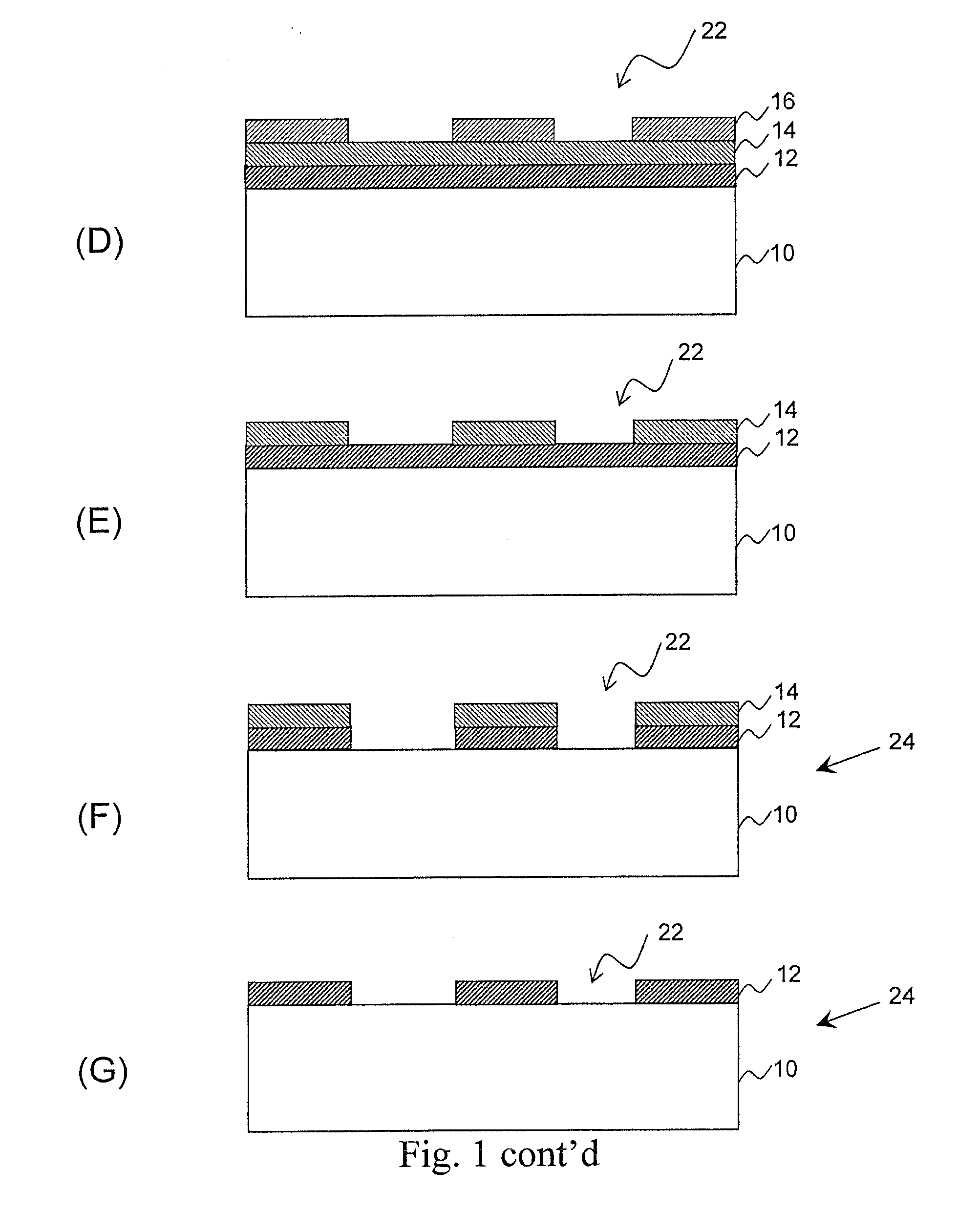

Image

Examples

example 1

Aluminum / Silicon Sol-Gel Hardmask

[0049]1. Polymer Synthesis

[0050]To prepare the polymer, 1.32 grams of phenyl trimethoxysilane (Gelest; Morrisville, Pa.), 6.54 grams of vinyl trimethoxysilane (Gelest), 14.06 grams of methyl trimethoxysilane (Gelest), 45.11 grams of aluminum diisopropoxide ethylacetoacetate (solution of 75% solids in IPA from Gelest, diluted to 40% solids with PGMEA), and 93.00 grams of PGMEA (Ultra Pure Solutions, Inc.) were added to a round-bottom flask. Over a 10-minute period, 17.15 grams of a 3N acetic acid solution (17.6% acetic acid and 82.4% water) were added slowly to the flask while stirring. The round-bottom flask was fitted with a distillation head, distillation column, and collection flask. The solution was then heated at 95° C. for 3 hours.

[0051]2. Hardmask Formulation

[0052]A hardmask formulation was prepared by mixing 12.03 grams of the polymer solution above (˜8.88% solids) with 6.36 grams of PGMEA, 16.4 grams of PGME, and 0.89 grams of a 0.4% solutio...

example 2

Titanium / Silicon Sol-Gel Hardmask

[0055]1. Polymer Synthesis

[0056]In this Example, the polymer was prepared by adding 1.21 grams of phenyl trimethoxysilane (Gelest), 6.00 grams of vinyl trimethoxysilane (Gelest), 11.01 grams of methyl trimethoxysilane (Gelest), 68.06 grams of titanium diisopropoxide (bis 2,4-pentanedione) (solution of 75% solids in IPA from Gelest, diluted to 40% solids with PGMEA), and 80.50 grams of PGMEA (Ultra Pure Solutions, Inc.) to a round-bottom flask. Over a 10-minute period, 17.08 grams of a 3N acetic acid solution (17.6% acetic acid and 82.4% water) were slowly added to the flask while stirring. The round-bottom flask was fitted with a distillation head, distillation column, and collection flask. The solution was then heated at 95° C. for 4 hours.

[0057]2. Hardmask Formulation

[0058]A hardmask formulation was prepared by mixing 6.01 grams of the polymer solution above (9.06% solids) with 17.85 grams of PGMEA, and 12.39 grams of PGME to make a 1.5% solids sol...

example 3

Titanium / Silicon Sol-Gel Hardmask 2

[0061]1. Polymer Synthesis

[0062]In this procedure, as second titanium / silicon sol-gel hardmask was prepared. To synthesize the polymer, 21.11 grams of methyl trimethoxysilane (Gelest), 32.40 grams of titanium diisopropoxide (bis 2,4-pentanedione) (75% solids in IPA, Gelest), and 117.50 grams of PGMEA (Ultra Pure Solutions, Inc.) were added to a round-bottom flask. Over a 10-minute period, 5.75 grams of a 3N acetic acid solution (17.6% acetic acid and 82.4% water) were added slowly to the flask while stirring. The round-bottom flask was fitted with a distillation head, distillation column, and collection flask, and the solution was heated at 95° C. for 4 hours.

[0063]2. Hardmask Formulation

[0064]A hardmask formulation was prepared by mixing 6.00 grams of the polymer solution above (9.56% solids) with 19.03 grams of PGMEA, 3.05 grams of PGME, and 0.72 grams of a 0.4% solution of benzyltriethylamino chloride (BTEAC) in PGME to make a 2.0% solids soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sizes | aaaaa | aaaaa |

| total weight | aaaaa | aaaaa |

| microelectronics structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com