Gas engine having intercooler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The illustrated embodiments of the present invention will be hereinafter described in detail.

[0036]It should be noted that, unless otherwise specified, the size, material, shape, and relative arrangement or the like of constituent components described in these embodiments are only illustrative examples and not intended to limit the scope of this invention.

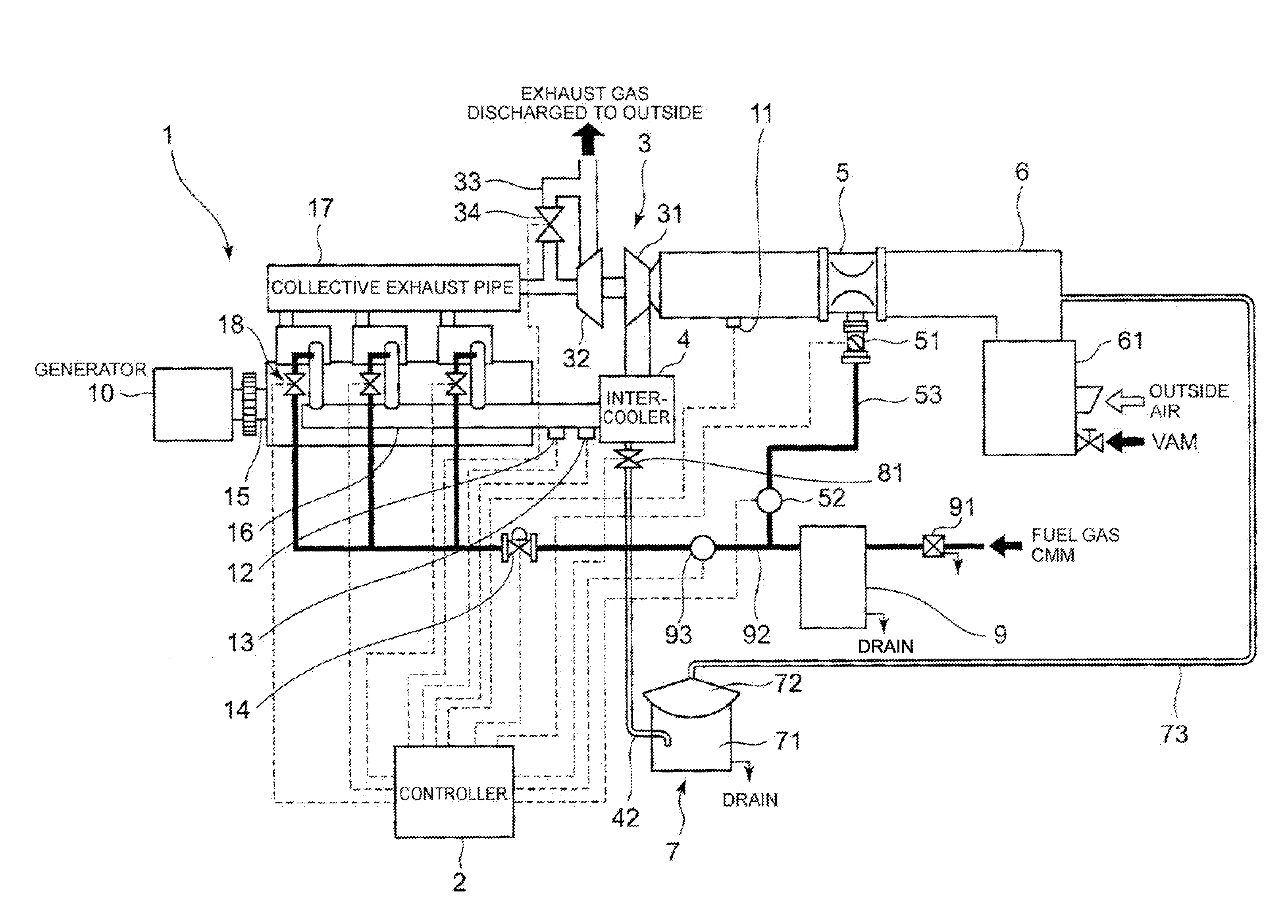

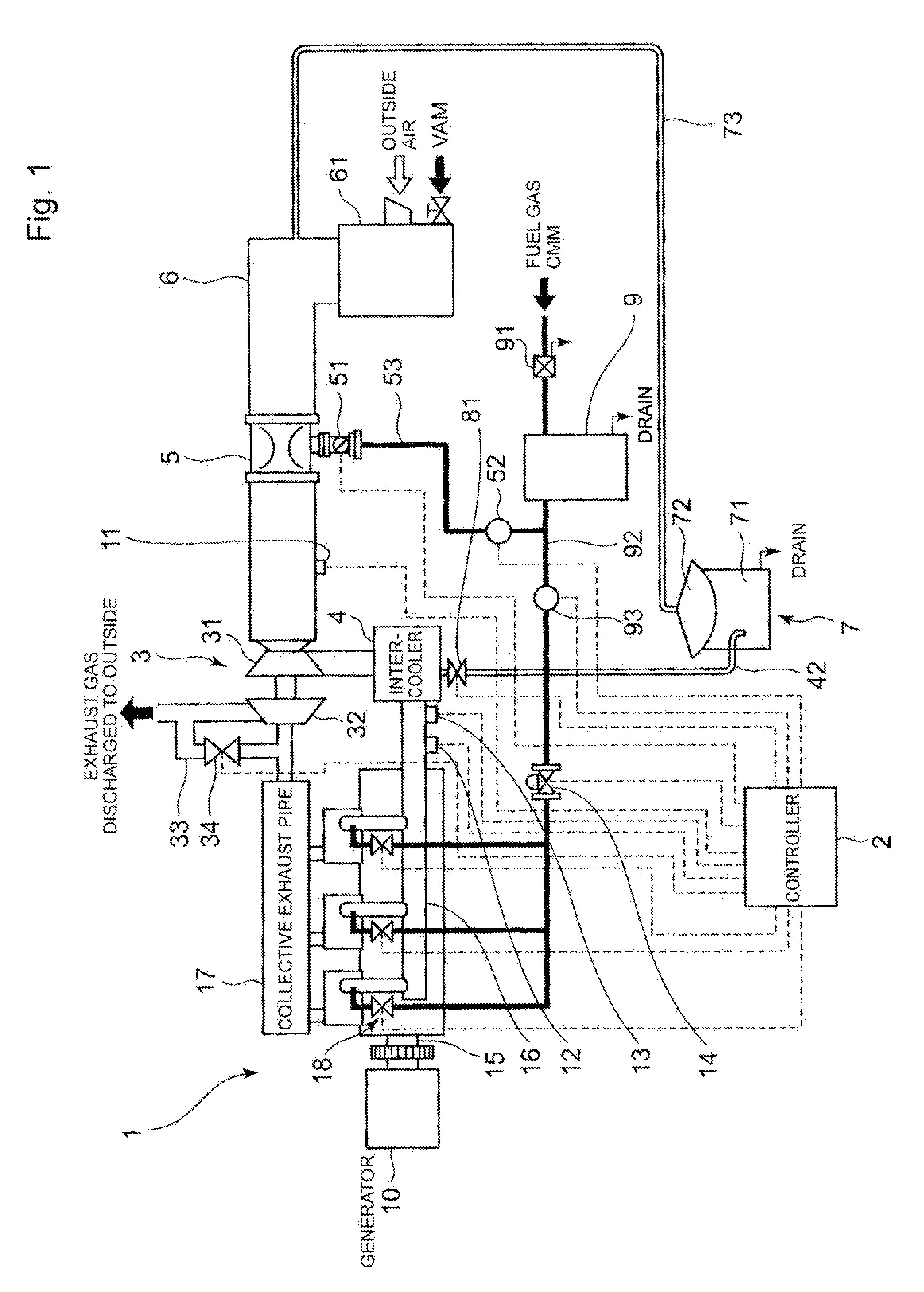

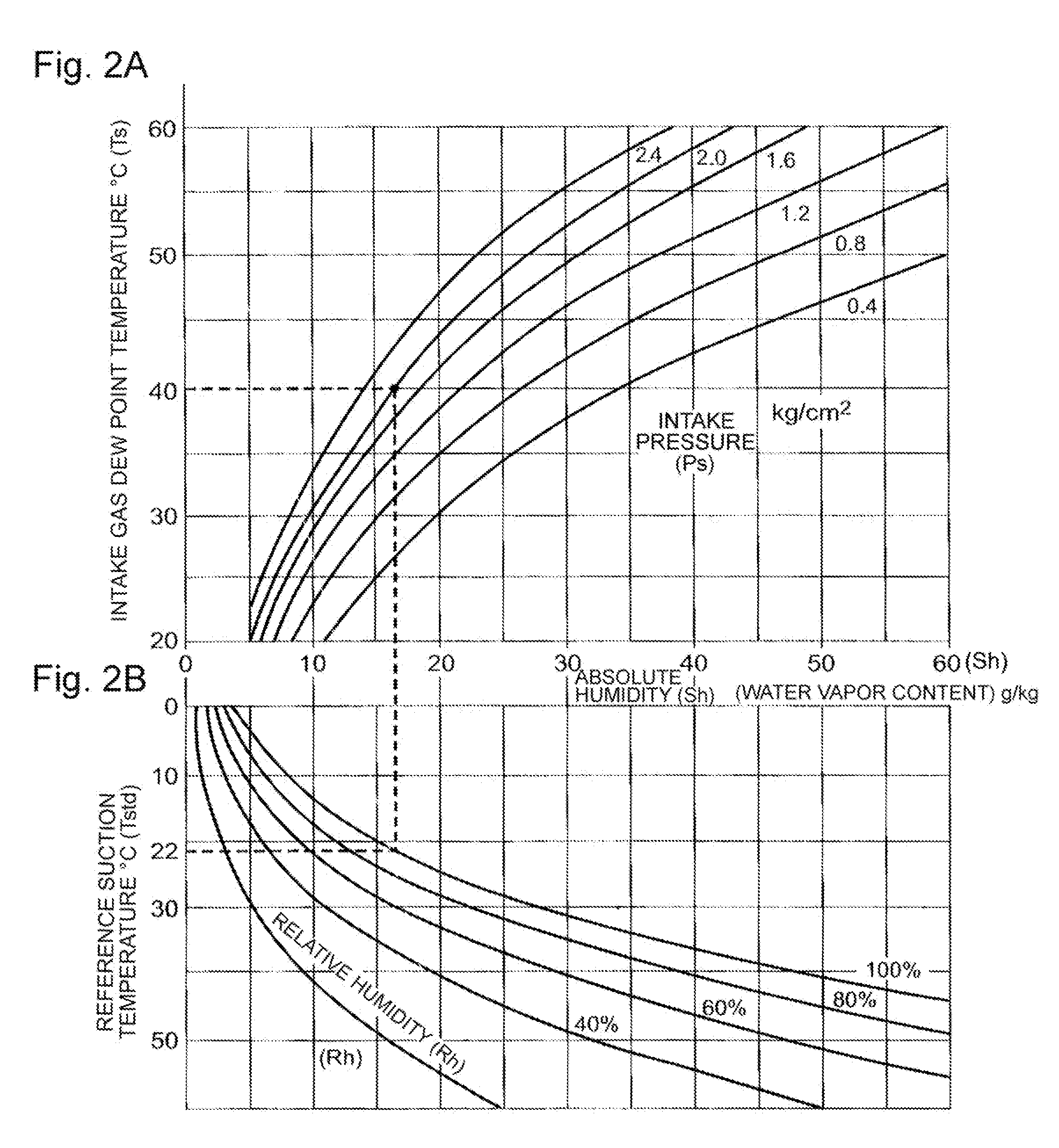

[0037]One embodiment of the gas engine according to the present invention will be described with reference to FIG. 1 to FIG. 3.

[0038]The power generating gas engine 1 of this embodiment is installed near a coal mine, and uses methane gas emitted from a coal mine as fuel gas and intake gas. In FIG. 1, a generator 10 is coupled to an output shaft 15 of the power generating gas engine 1 (hereinafter referred to as gas engine 1).

[0039]An oil bath filter 61 is disposed in an intake system upstream of an intake pipe 6 which is an intake passage forming member connected to the gas engine 1. Ventilation air methane VAM gas released t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com