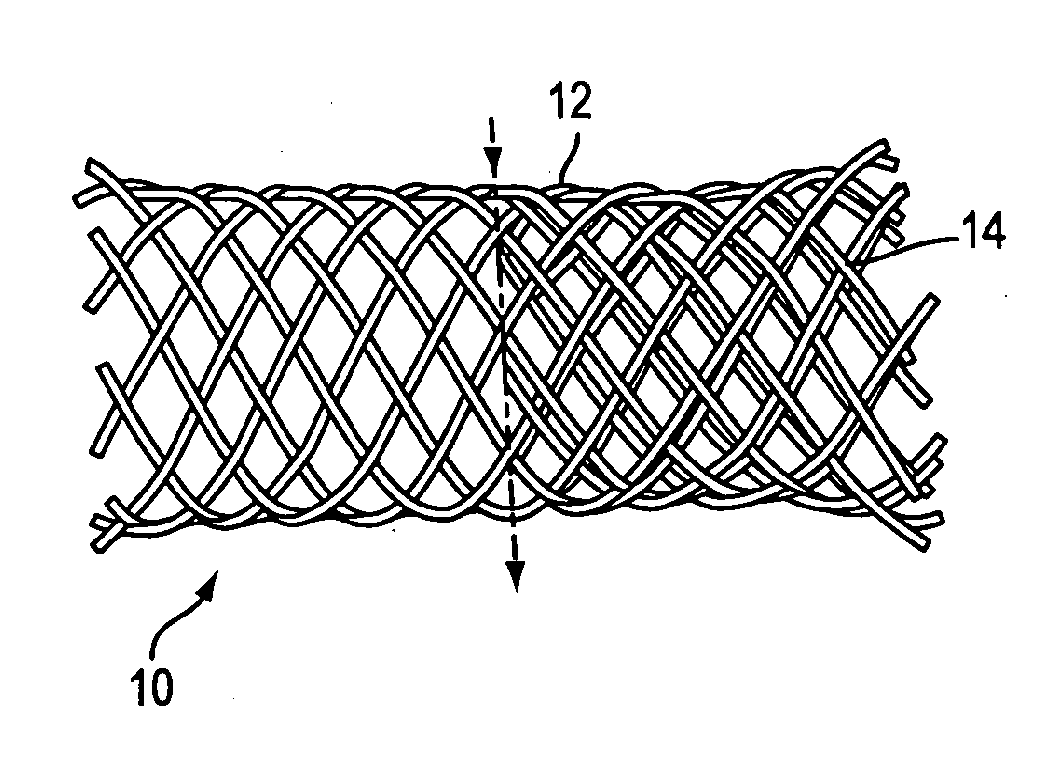

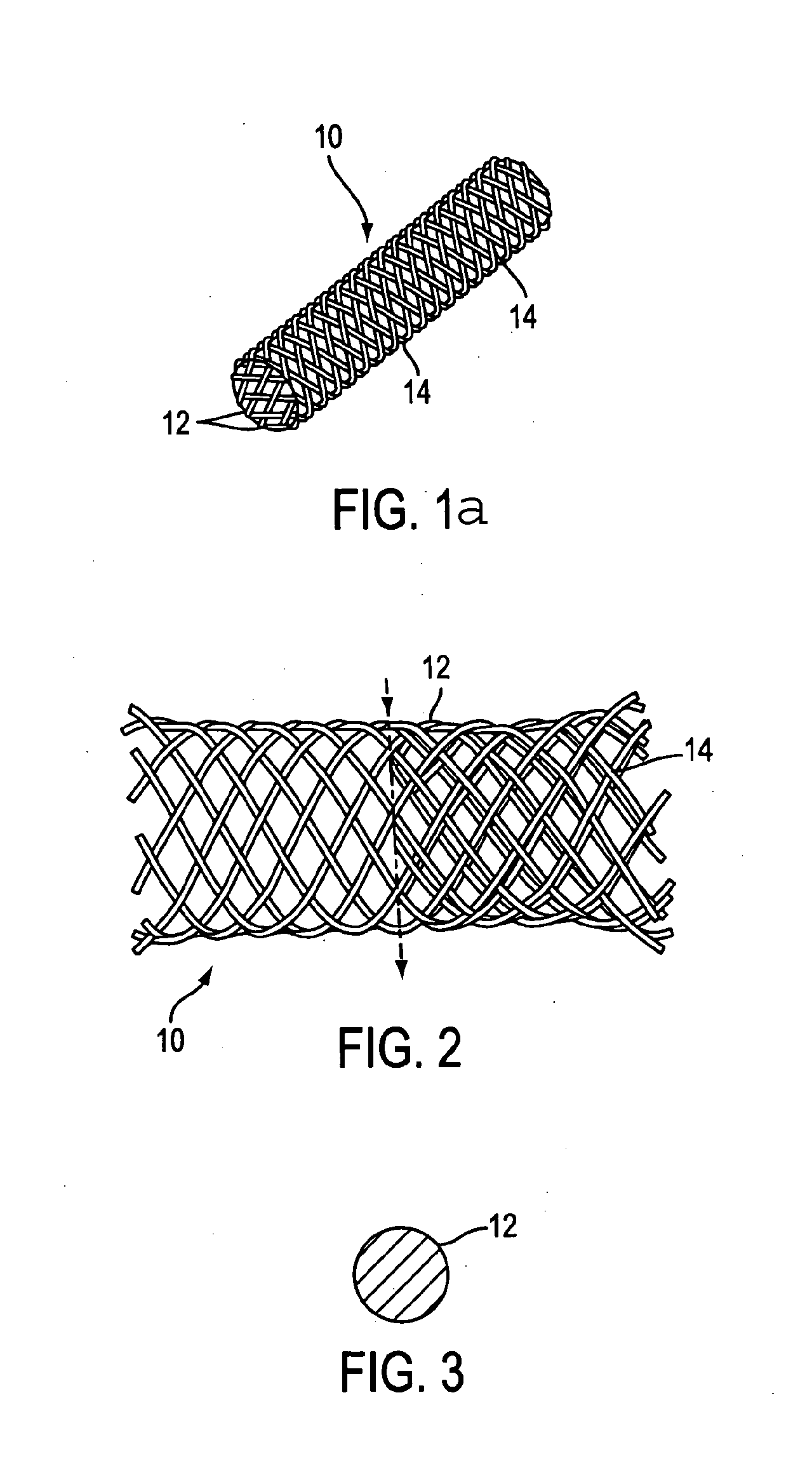

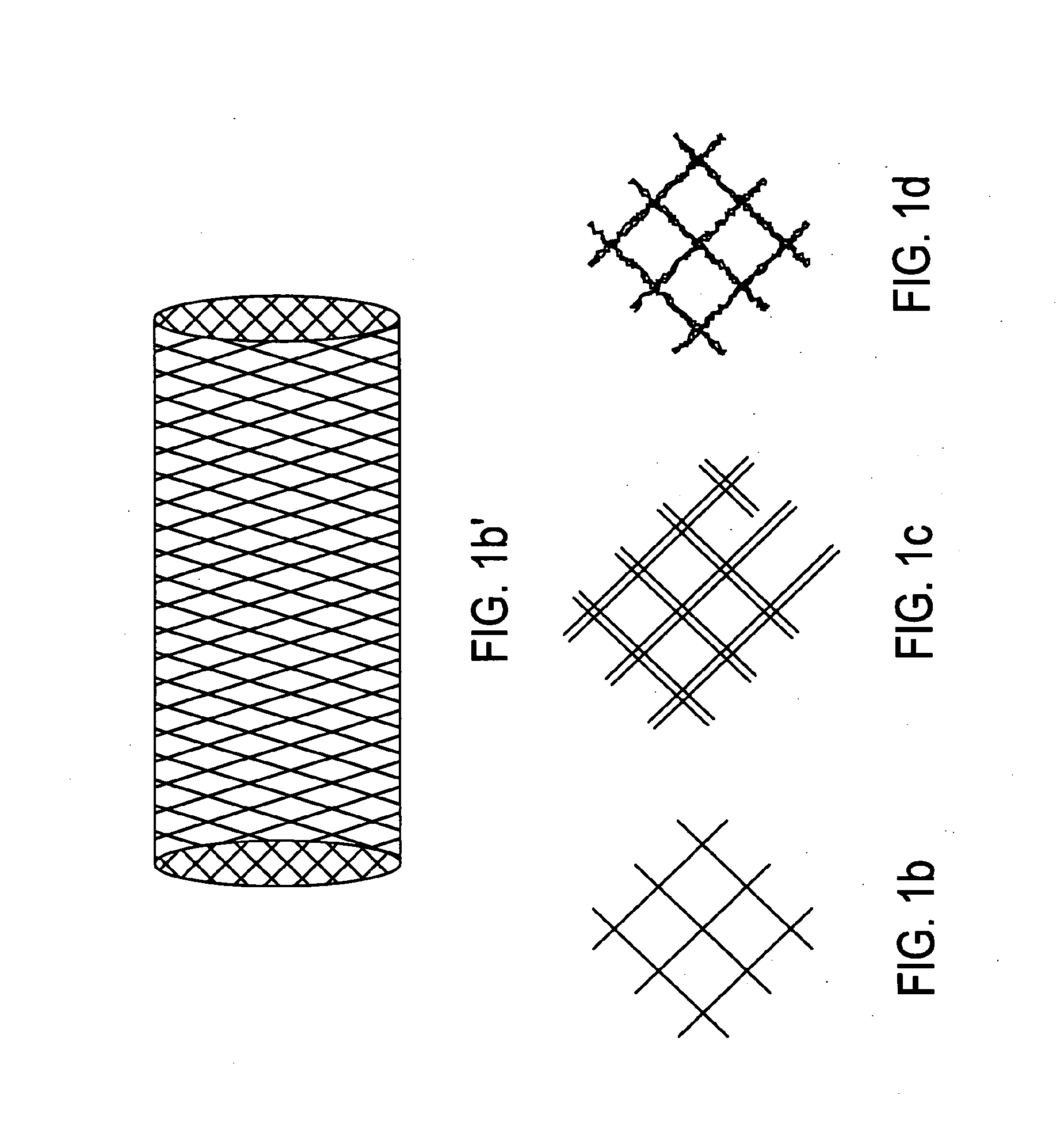

Disintegrating stent and method of making same

a technology of disintegrating stents and medical prostheses, which is applied in the field of disintegrating implantable medical prostheses, can solve the problems of bioabsorbable stents having their own disadvantages, affecting the quality of life of patients,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0067]One method of creating multiple fracture initiation sites in a biodegradable polymer is to create a structure having more amorphous and less crystalline regions in the material.

[0068]Methods for making polycrystalline monofilaments are generally known. For example, methods for making PLA monofilaments are described in detail in U.S. patent application Ser. No. 08 / 08 / 904,467, filed Aug. 1, 1997. Generally, PLA monofilaments may be produced by a process involving seven general steps as summarized herein. Methods of making monofilaments from other polycrystalline polymers, including but not limited to the polymers enumerated hereinabove, are equally well known to those of ordinary skill in the art, and this example is not intended to limit the present invention in any way.

[0069]First, a polymer formed of poly-L-lactic acid is brought to an elevated temperature above the melting point, preferably 210.degree.-230.degree. C. Second, the material is then extended at the elevated temp...

example 2

[0073]Mechanical properties generally increase with increasing molecular weight. For instance, the strength and modulus of polycrystalline polymers generally increase with increasing molecular weight. Conversely, degradation time generally decreases with decreasing initial molecular weight (i.e., a stent made of a low molecular weight polymer is bioabsorbed more quickly than a stent made of a high molecular weight polymer). Moreover, the molecular weight and mechanical properties of the material generally decreases as degradation progresses. Accordingly, in addition to, or as an alternative to, the creation of a heterogeous molecular structure to promote controlled disintegration and fracture, the stent material may be subjected to post-extrusion or molding operations to create pre-selected “weak spots,” localized pre-degradation of the molecular weight of the crystalline structure of the polymer.

[0074]One method of creating pre-degraded regions in a monofilament is to mask some por...

example 3

[0075]In addition to manipulating the molecular structure during or after extrusion, mechanical features such as stress concentrations, fissures, notches grooves, indentations or surface contours may be designed into the implant to cause predictable, controlled fracture and / or disintegration. FIGS. 12a-c and 13 illustrate types of mechanical features may be introduced into the surfaces of stent materials to facilitate planned and controlled fracture.

[0076]Such periodic fracture initiation sites are designed such that they are not deleterious enough to initiate fracture in full-strength material. However, when degradation occurs and the material loses strength, the stress concentrations or fissures become more significant relative to the strength of the material and serve as points of weakness in the device in order to facilitate disintegration. The methods of making the features include lathe turning, milling, drilling, die-forming, laser curing, and chemical etching. Die chatter ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com