Reactor

a technology of reactors and reactors, applied in the field of reactors, can solve the problems of requiring laborious reactor transport, affecting the efficiency of the reactor, and the risk of contamination during fermentation is particularly critical, and achieves the effects of simple gas distribution, good mixing, and effective surface gas introduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

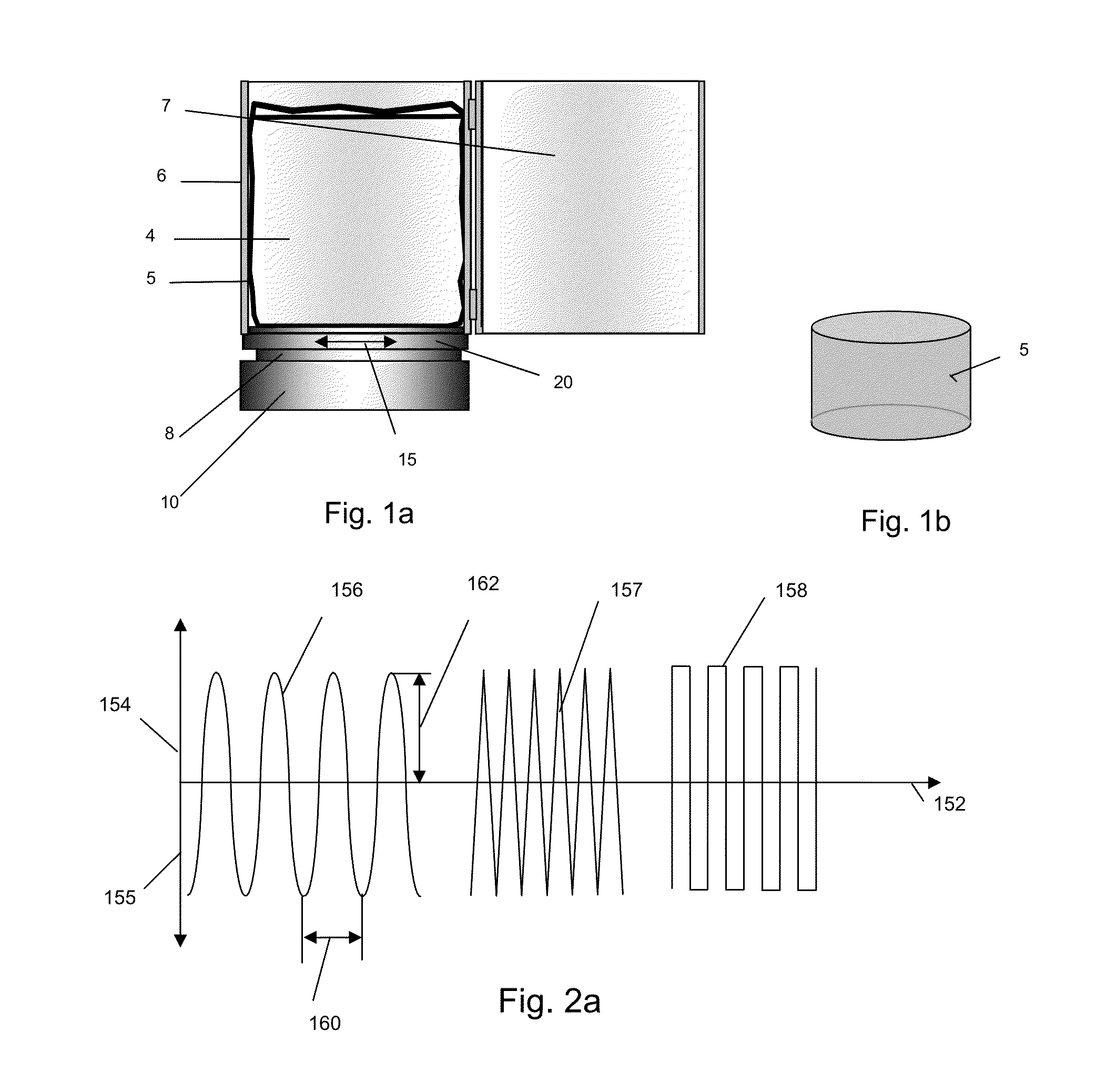

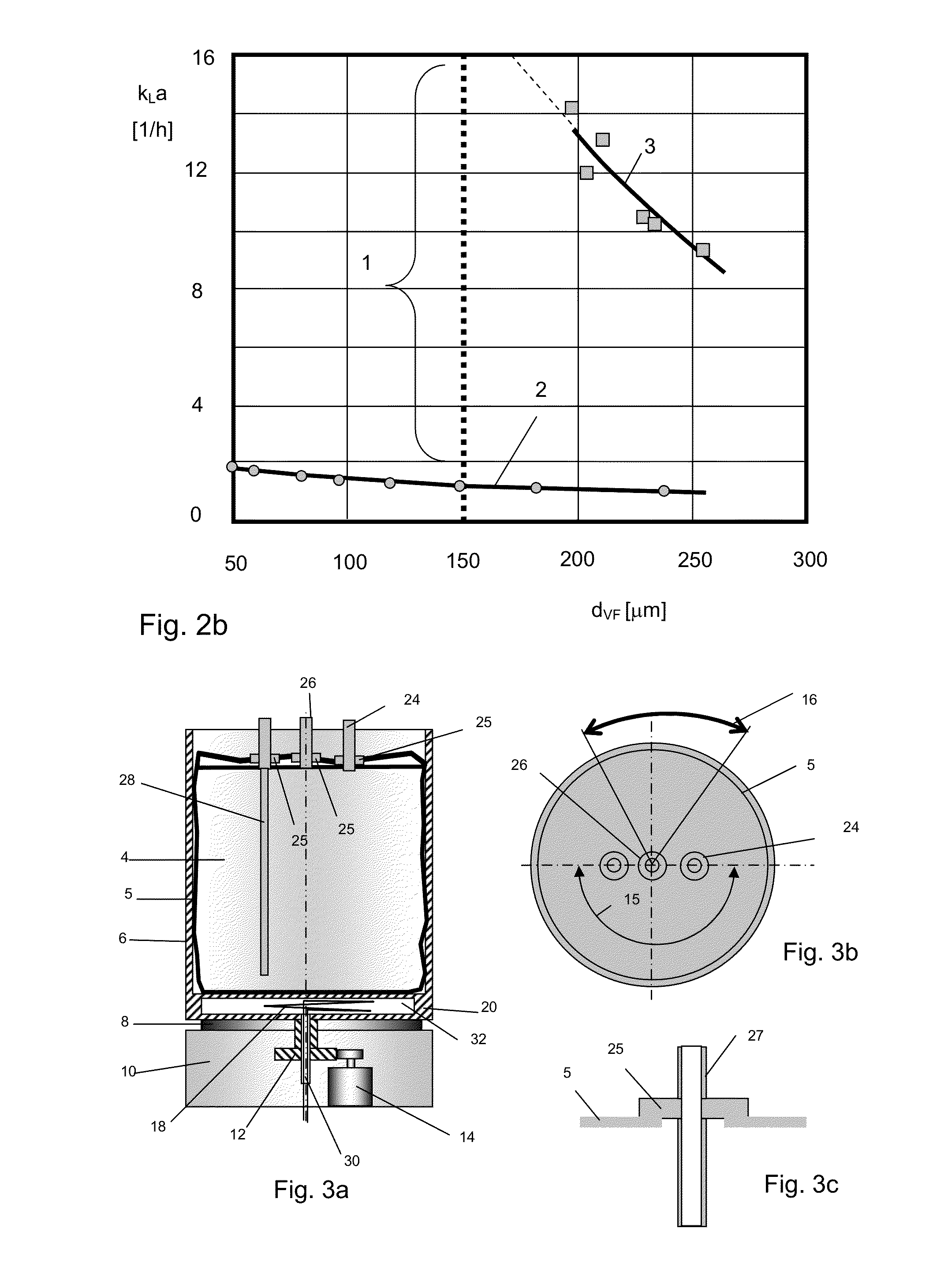

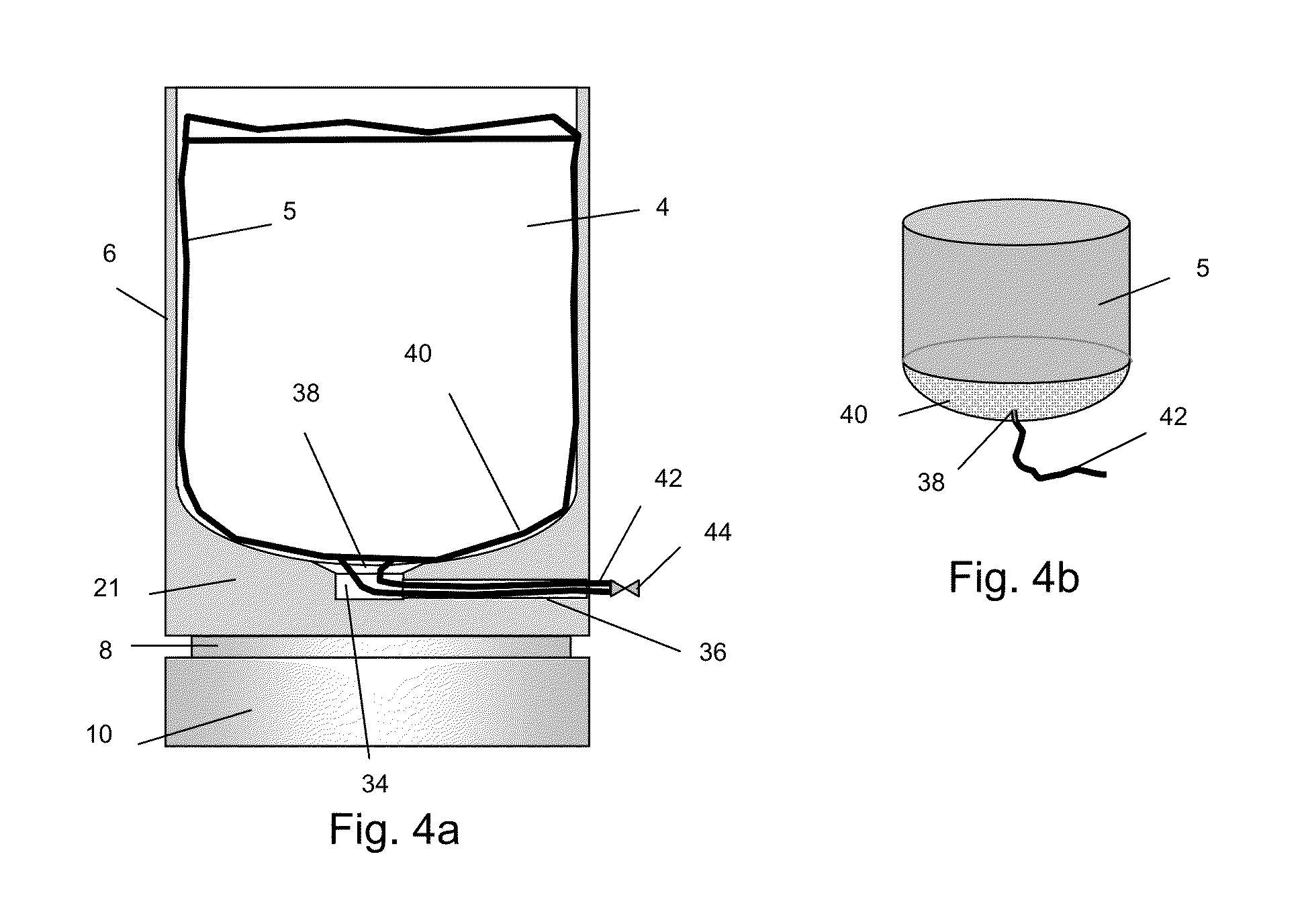

[0028]By means of the internals, distribution processes and / or mixing reactions can be carried out in a simple manner and with the same intensity as in a conventional stirred tank. In this design, a shaft passage can be dispensed with completely. The internals again may be supplied with material streams or energy streams via the side facing away from the product, which streams are introduced into the medium or discharged therefrom by diffusion, convection, heat conduction and / or radiation. In this manner, for the first time, in addition to mixing, numerous process engineering unit operations such as gas distribution, oxygen input by means of membrane gas introduction, heat transport, irradiation and / or particle retention can be carried out in a single-use reactor in a gentle manner and with an efficiency comparable to a stirred tank. The reactions and transport processes proceed in this case directly at the internals. Therefore, the sites of the greatest hydrodynamic energy density ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com