Liquid filtration media containing melt-blown fibers

a technology of melt-blown fibers and filtration media, which is applied in the direction of filtration separation, machine/engine, separation process, etc., can solve the problems of damage to the engine, unacceptable particle levels passing through the filter media, and detrimental to engine performance, so as to reduce fouling and widen the pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

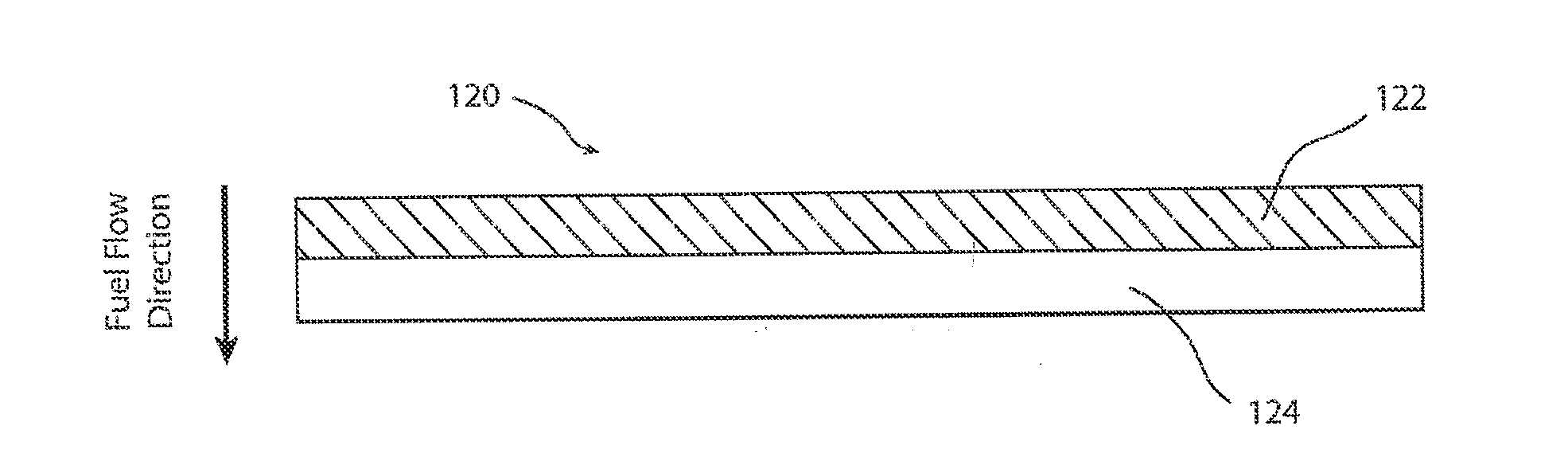

[0035]The present invention is directed in part to filter media and filter elements for the removal of contaminant material from a liquid fuel stream. The filter elements and media are configured for removal of additional contaminants besides hard particles, these additional contaminants including (for example) waxes, asphaltenes, sterol glucosides, steryl glucosides, sterol glycosides, and fuel degradation products—collectively referred to as fuel contamination products. The filter elements and media allow for improved filter performance and longevity.

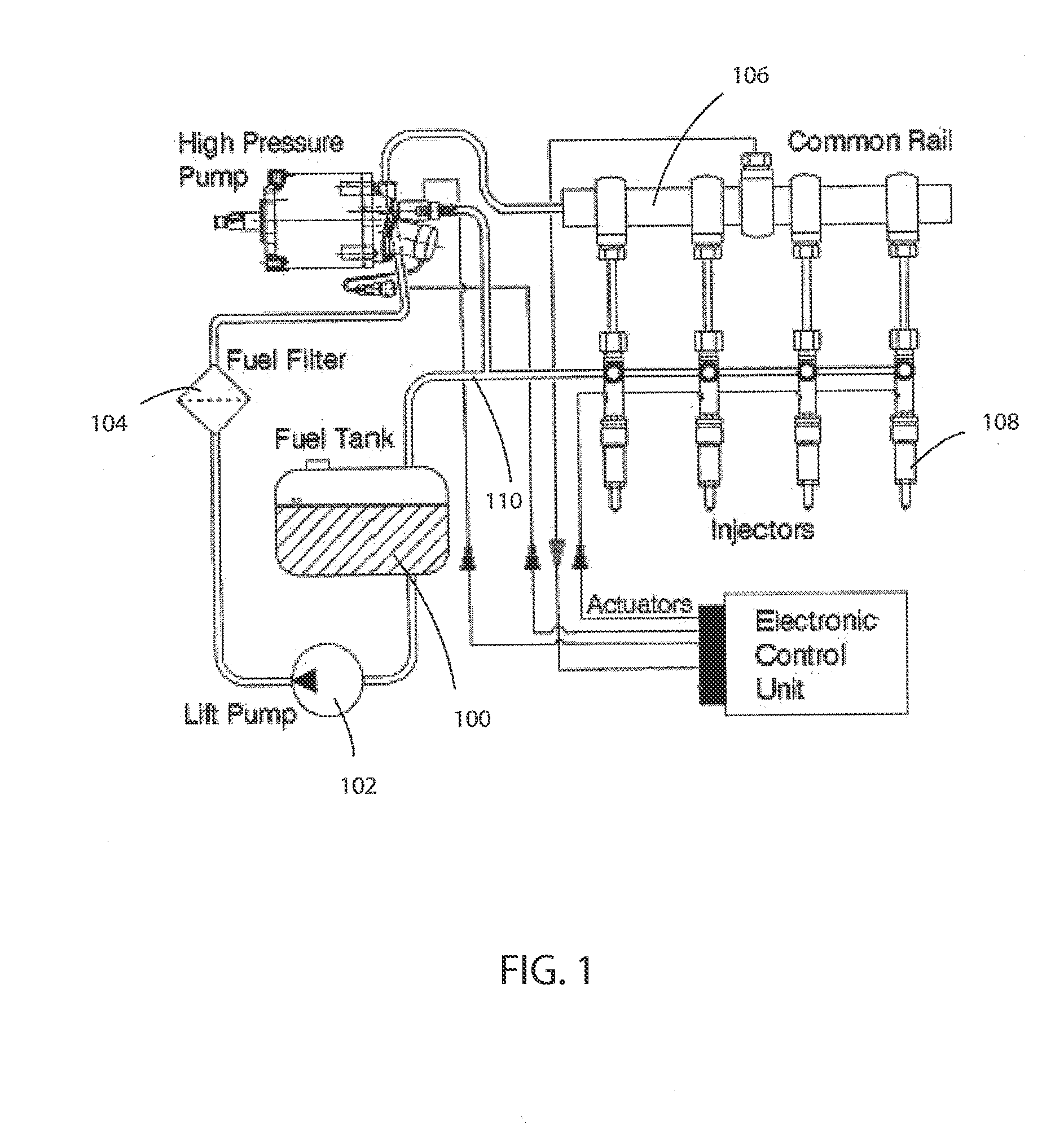

[0036]Although existing fuel filtration media can perform adequately in removing particulate contaminants from liquid fuels, the existing media can prematurely foul by buildup of contaminants other than traditional particulates. This premature fouling appears to be particularly pronounced in situations where fuel undergoes repeated heating and cooling cycles, such as in common rail systems used on many diesel engines.

[0037]FIG. 1 is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com