Liquid ejecting head, liquid ejecting apparatus, and piezoelectric element

a liquid ejecting and apparatus technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric/electrostriction/magnetostriction machines, printing, etc., can solve problems such as inability to arise, degrading piezoelectric properties, and increasing the area of electrical conduction failure in the lower electrode, so as to improve piezoelectric properties and improve the ability to resist voltage. , the effect of improving crystallin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

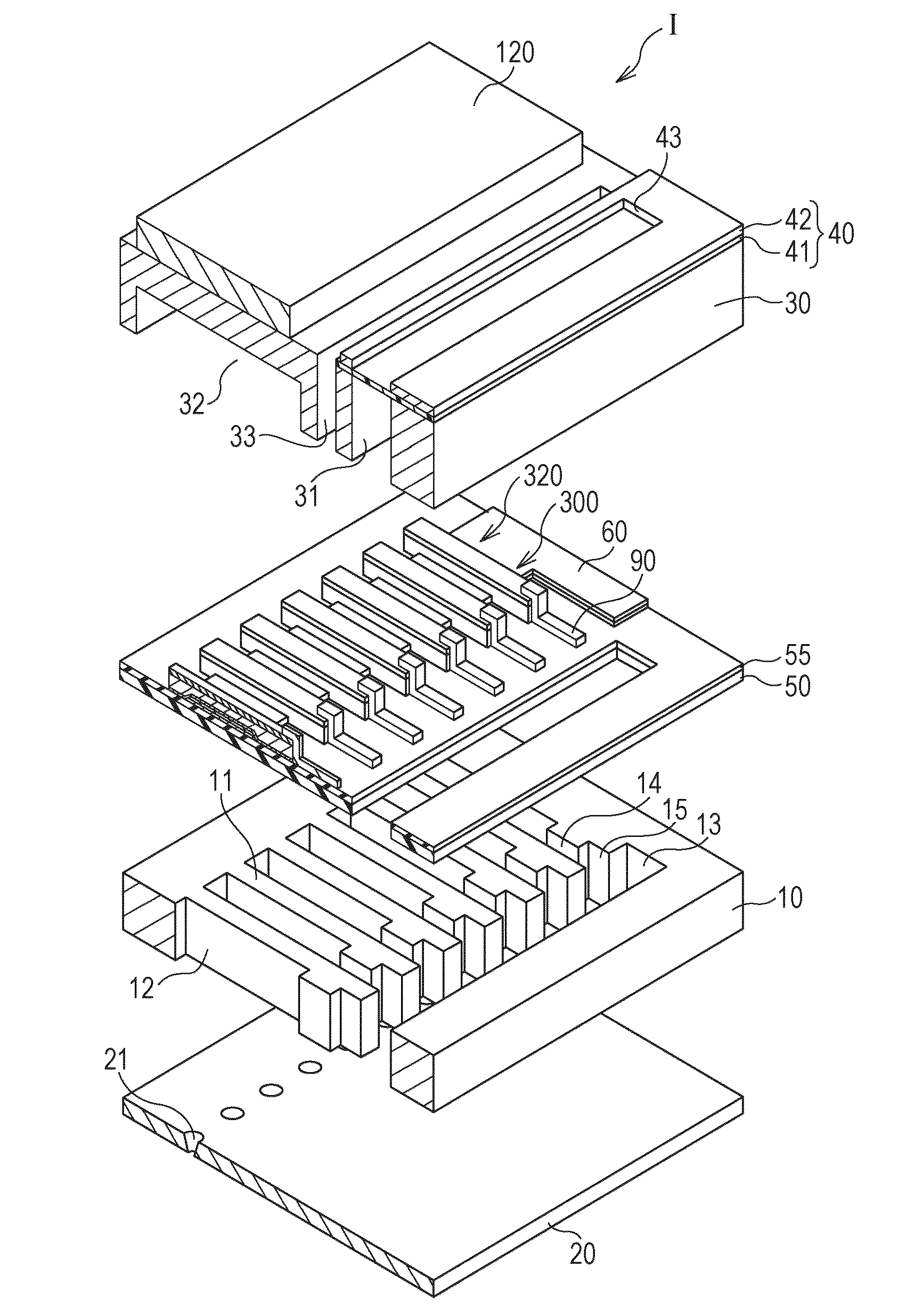

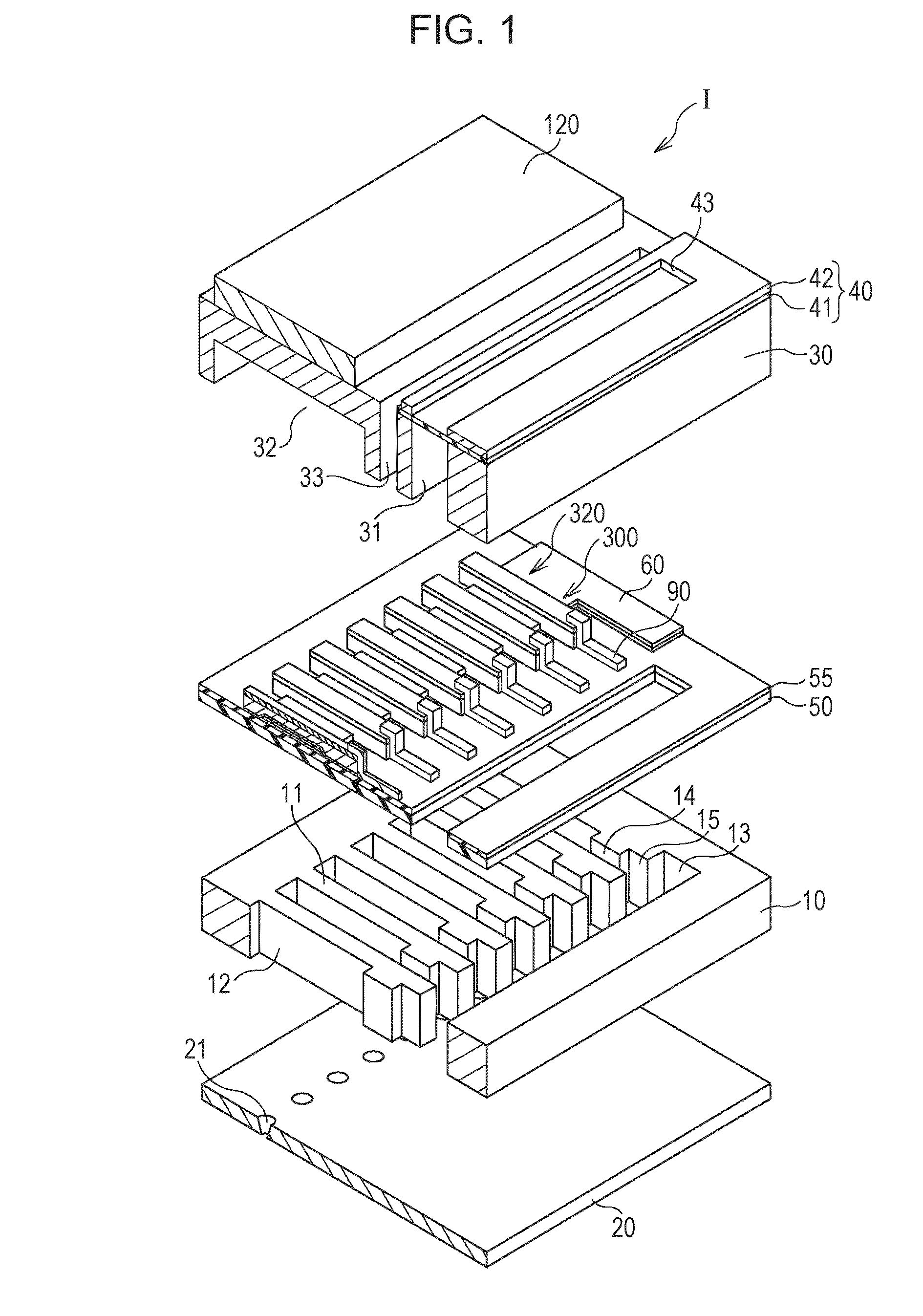

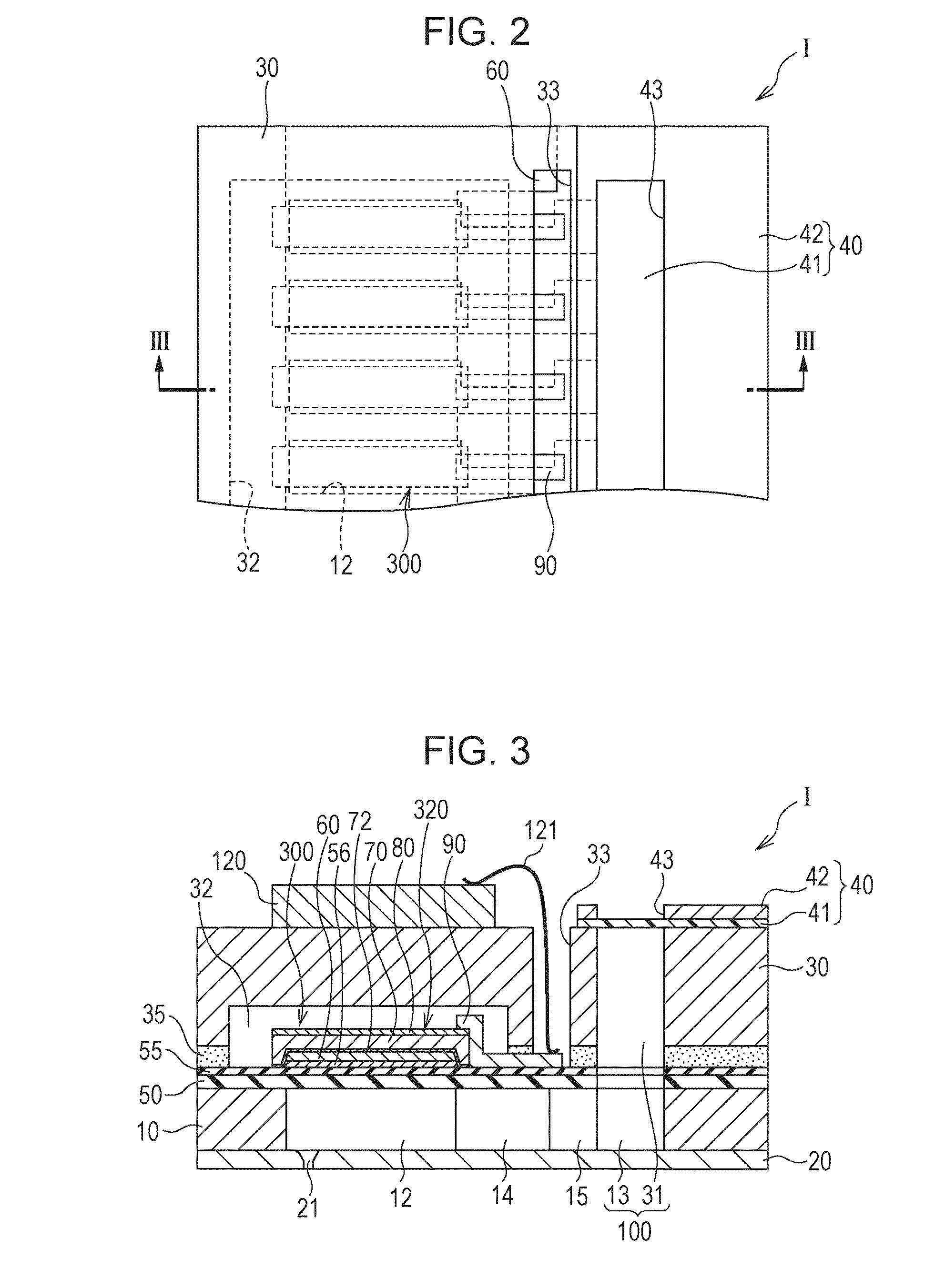

Image

Examples

example

[0100]The invention will be further described in detail with reference to Examples below. However, the invention is not limited to the following Example. FIGS. 9A and B are a schematic representation of the structures of the piezoelectric elements of Samples 1 to 17 and Comparative Samples 1 to 3.

Samples 1 to 5

[0101]Table 1 shows the structures of the piezoelectric elements of Samples 1 to 5 and Comparative Samples 1 to 3.

Preparation of Composition for Forming Lanthanum Nickelate Film

[0102]For this composition, lanthanum acetate 1.5-hydrate (La(CH3COO)3.1.5H2O) and nickel acetate tetrahydrate (Ni(CH3COO)2.4H2O) were used as the main constituents, and propionic acid was used as the solvent. The mixture of these materials was heated to 120° C. on a hot plate to ion-exchange the acetates by the propionic acid and stirred for about one hour, and to adjust the concentration of the lanthanum acetate and the nickel acetate in the mixture to be 0.25 mol / L. The solution was cooled to yield a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com