Photosensitive polysiloxane composition and uses thereof

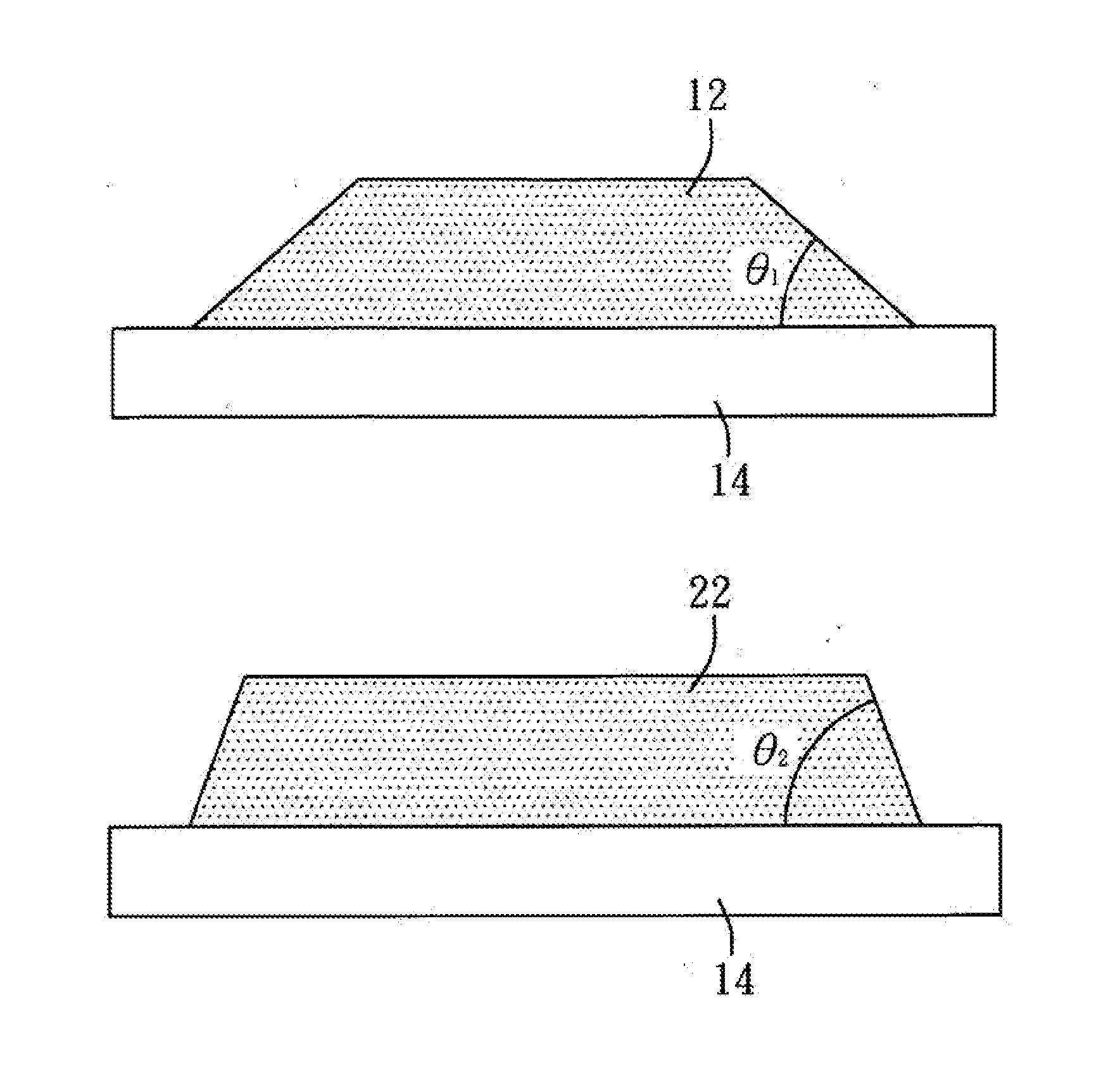

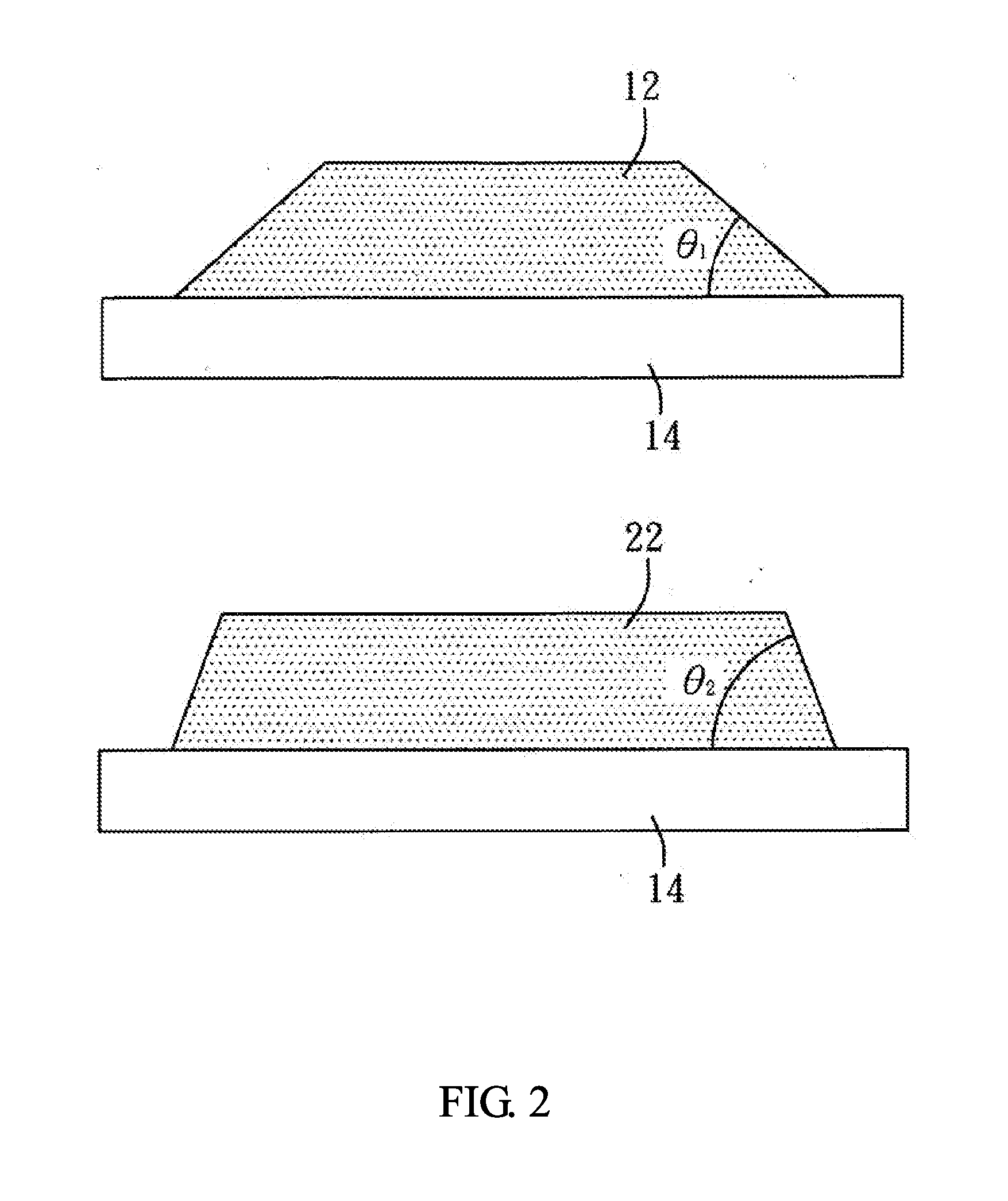

a polysiloxane composition and polysiloxane technology, applied in the field of photosensitive polysiloxane composition and thin film and device, can solve the problems that the low tapered angle of a pattern of photosensitive composition cannot be accepted in this field, and the surface flatness of the surface is not good, so as to achieve good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthesis example

Synthesis of Polysiloxane (A-1)

[0163]Following adding 0.30 mole of methyl trimethoxy silane (MTMS), 0.65 mole of phenyltrimethoxysilane (hereinafter referred to as PTMS), 0.05 mole of 3-(triethoxysilyl) propyl succinic anhydride (hereinafter referred to as GF-20) and 200 g of propylene glycol monoethyl ether (hereinafter referred to PGEE) into a 500 ml three-necked flask, an aqueous oxalic acid solution (0.40 g oxalic acid / 75 g water) was added at room temperature with stirring within 30 minutes. Next, the flask was immersed at 30° C. in oil bath and stirred for 30 minutes. Then, within 30 minutes, the temperature of the oil bath was raised to 120° C. After the solution temperature was dropped to 105° C., heating was resumed with stirring for polymerization for 6 hours. Then again, the solvent was removed using distillation to obtain the polysiloxane (A-1). The kinds and used amounts of the raw materials of the polysiloxane (A-1) are shown in Table 1.

Synthesis of Polysiloxane (A-2) ...

example 1

[0167]One-hundred parts by weight of the used amount of the polysiloxane (A-1), 2 parts by weight of the ortho-naphthoquinone diazide sulfonic acid ester (B−1) formed from 1-[1-(4-hydroxyphenyl)propyl]-4-[1,1-bis(4-hydroxyphenyl)ethyl]benzene and ortho-naphthoquinone diazide-5-sulfonic acid (B−1), and 0.5 parts by weight of alkali-soluble resin containing the silyl group (C-1) were mixed and dissolved in 100 parts by weight of the propylene glycol monomethyl ether acetate (D−1) completely, so as to form the photosensitive polysiloxane composition of Example 1.

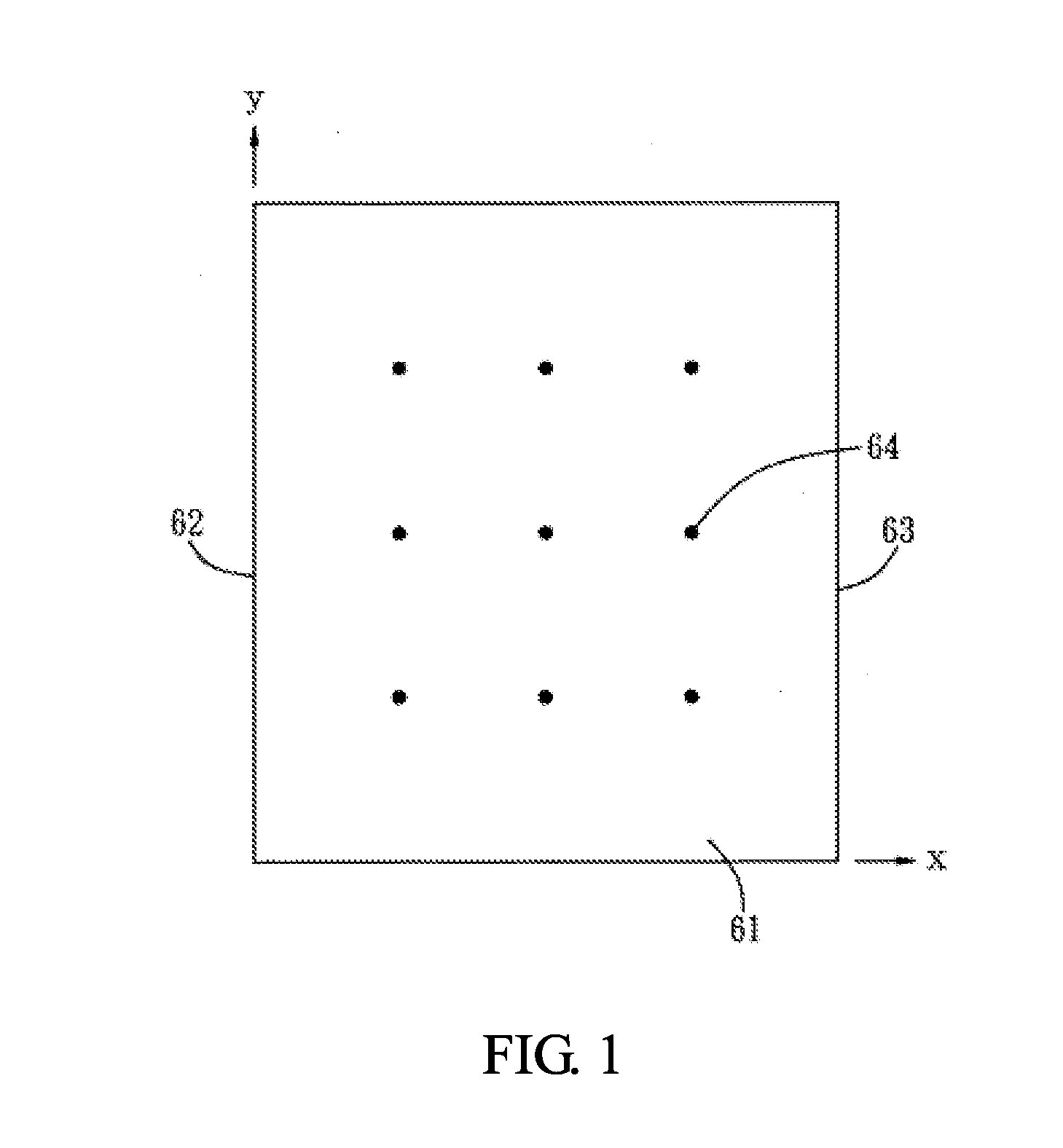

—Formation of Thin Film on Glass—

[0168]Various photosensitive polysiloxane compositions were spin coated independently on a prime glass substrate of 100×100×0.7 mm in size, and then pre-baked for 2 minutes at 100° C. to obtain a pre-baked coating film of about 2 μm in thickness. And then, the pre-baked coating film was placed under the light mask with a given pattern, and ultraviolet light of 140 mJ / cm2 was used to irradiate th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| photosensitive | aaaaa | aaaaa |

| Ra | aaaaa | aaaaa |

| alkali-soluble | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com