Cleaning composition for semiconductor substrate and cleaning method

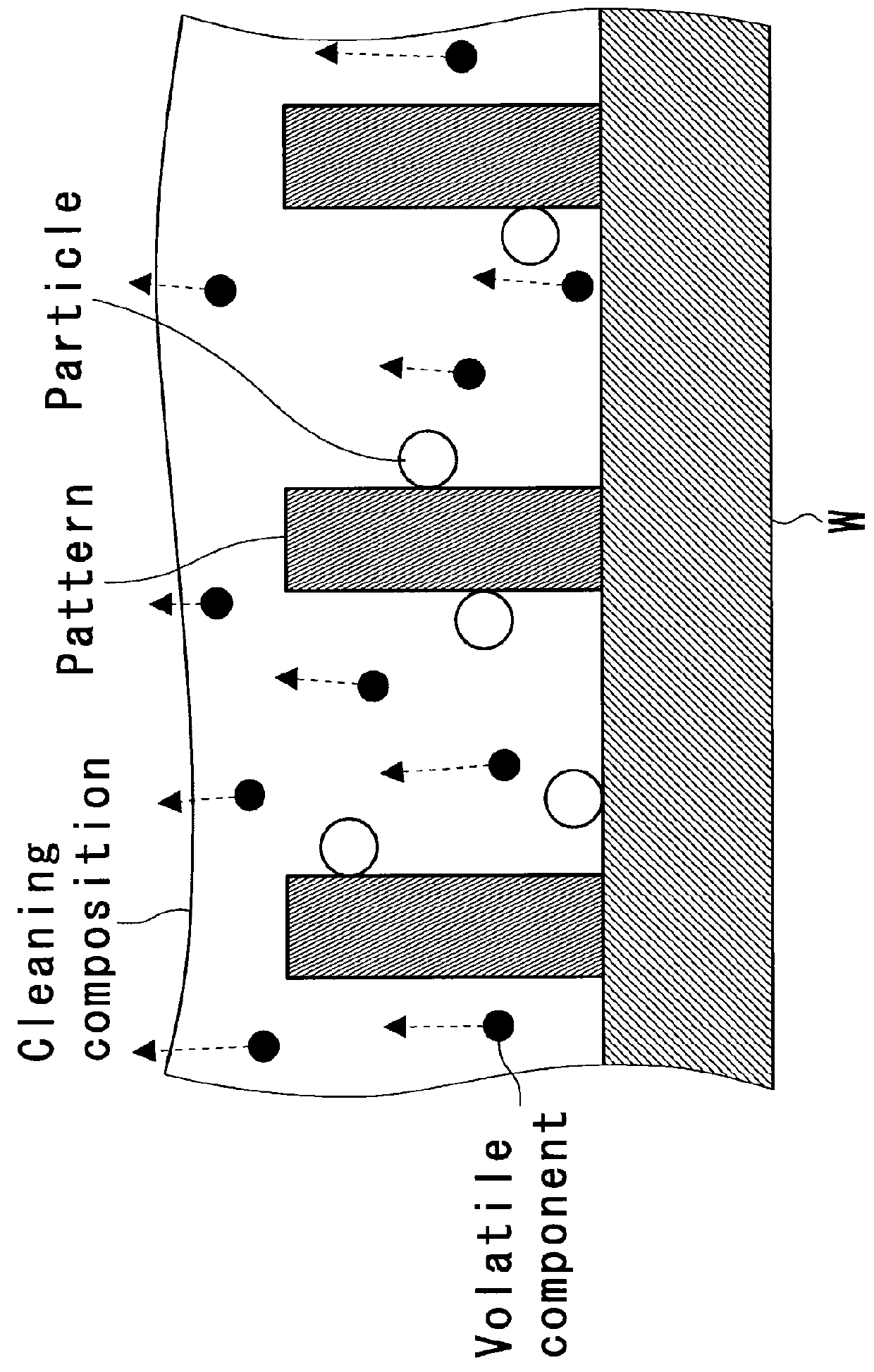

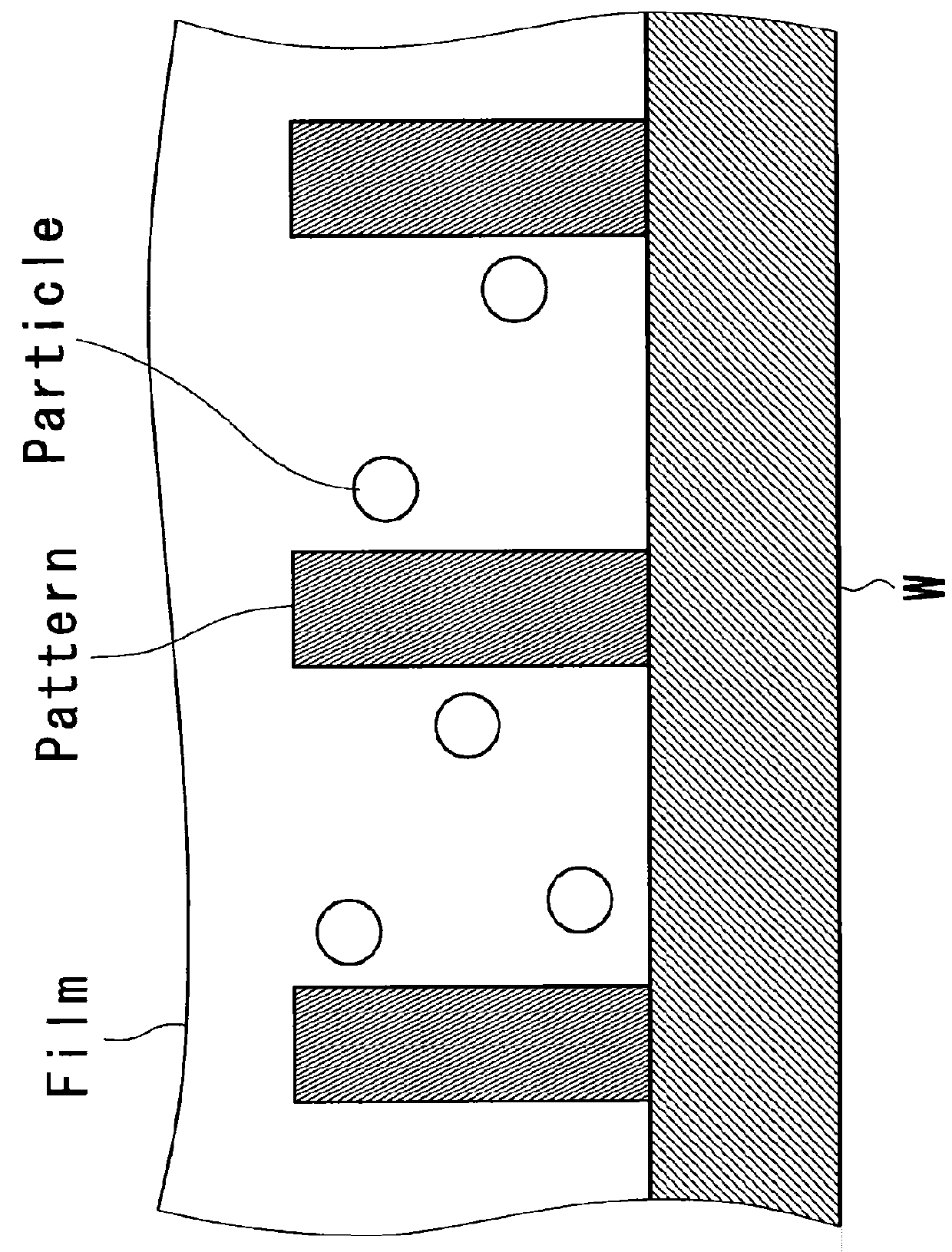

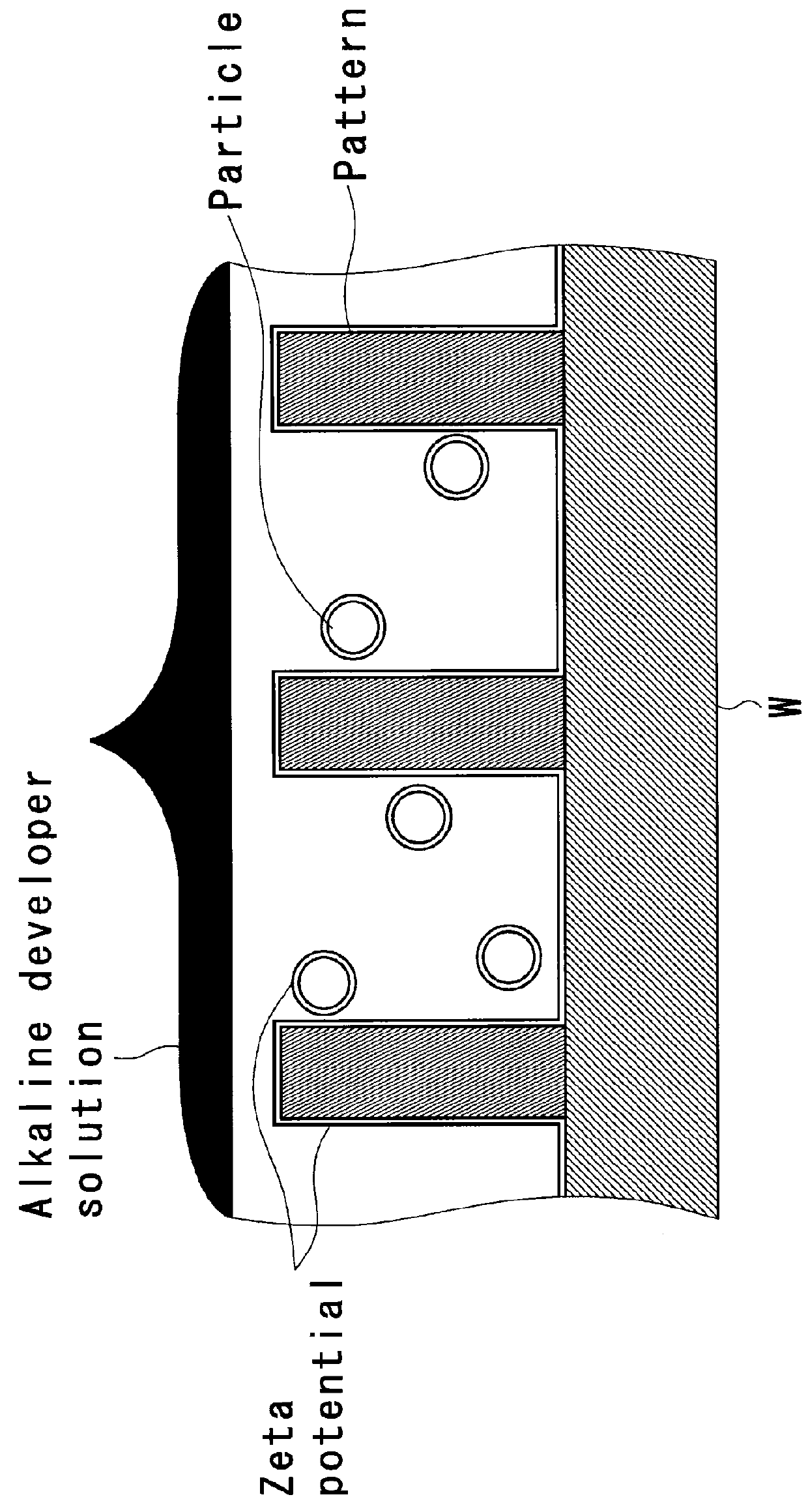

a technology for cleaning compositions and semiconductor substrates, applied in detergent compositions, detergent mixture preparations, detergent compounding agents, etc., can solve the problems of difficult removal of fine particles and/or attached particles between the pattern walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

production example 1

[0117]A monomer solution was prepared in which 100 g (100 mol %) of the compound (M-1) and 7.29 g (7 mol %) of azobisisobutyronitrile (AIBN) were dissolved in 100 g of 2-butanone. A 1,000 mL three-neck flask charged with 100 g of 2-butanone was purged with nitrogen for 30 min. The nitrogen purge was followed by heating to 80° C., and the monomer solution was added dropwise with stirring over 3 hrs using a dropping funnel. The time of the start of the dropwise addition was regarded as the time of the start of the polymerization reaction, and the polymerization was allowed for 6 hrs. After completing the polymerization, the reaction solution was cooled to no greater than 30° C. The reaction solution was concentrated in vacuo to give a mass of 150 g, and thereto were charged 150 g of methanol and 750 g of n-hexane to permit separation. After the separation, the underlayer liquid was recovered. To the recovered underlayer liquid was charged 750 g of n-hexane, and again purified through ...

production examples 2 to 22

[0118]Polymers (P-2) to (P-22) were synthesized in a similar manner to Production Example 1 except that the compound used and the combination were changed as shown in Table 1.

TABLE 1MonomerWeight averageDispersitycompositionYieldmolecularindexPolymertyperatio (mol %)(%)weight (Mw)(Mw / Mn)Production Example 1P-1M-11008010,5001.52Production Example 2P-2M-21007910,4001.51Production Example 3P-3M-31008010,0001.55Production Example 4P-4M-4 / M-570 / 308010,5201.53Production Example 5P-5M-1 / M-690 / 10819,9001.50Production Example 6P-6M-4 / M-680 / 207810,2001.51Production Example 7P-7M-6 / M-850 / 507910,4501.52Production Example 8P-8M-3 / M-670 / 308210,0001.52Production Example 9P-9M-1 / M-950 / 50847,4001.35Production Example 10P-10M-1 / M-1060 / 408310,3001.52Production Example 11P-11M-6 / M-1140 / 607811,0001.51Production Example 12P-12M-6 / M-1240 / 60829,8001.50Production Example 13P-13M-6 / M-1340 / 60839,5001.53Production Example 14P-14M-1 / M-1460 / 40829,9001.52Production Example 15P-15M-6 / M-1560 / 408110,3001.55Productio...

example 1

[0119]The polymer (P-1) in an amount of 100 parts by mass, and 7,400 parts by mass of 4-methyl-2-pentanol (MIBC) were mixed to prepare a homogenous solution. This solution was filtered through a filter made of high density polyethylene (HDPE) (pore size: 5 nm, PhotoKleen EZD, manufactured by Japan Pall Corporation). A decrease of the particles having a diameter of no greater than 150 μm in the liquid to 10 particles / mL was ascertained by Liquld-Borne Particle Sensor (KS-41B, manufactured by Rion Co., Ltd.), and thus a cleaning composition (D-1) was prepared. The solid content concentration was about 1.5% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com