Method of producing thermoelectric material

a thermoelectric device and material technology, applied in the direction of thermoelectric device junction materials, material nanotechnology, conductive materials, etc., can solve the problems of increasing zt, low-cost thermoelectric devices, and inability to provide a simple approach to large-scale manufacturing,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The present invention discloses a process for determining an optimum range of compositions for a thermoelectric material system, within which the material system may exhibit generally high figure of merit values. As such, the process has utility for improving the efficiency of experimental design and production of thermoelectric materials.

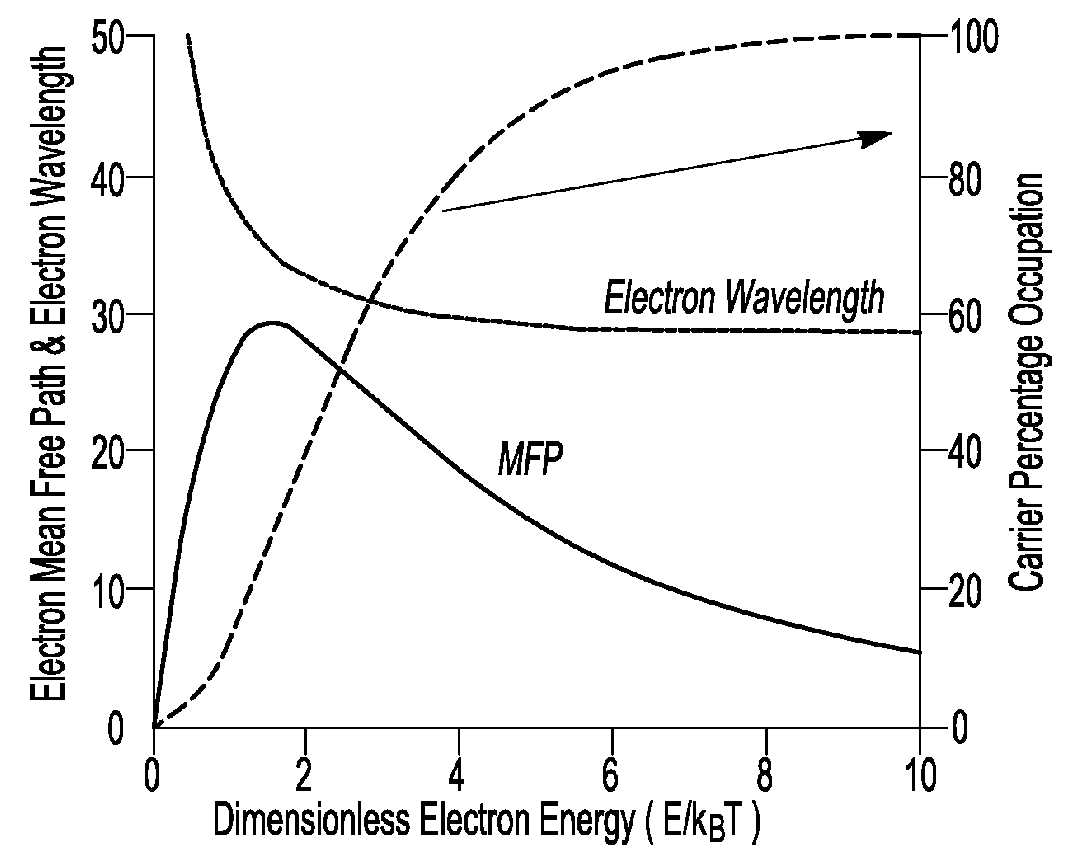

[0030]The process for determining an optimum range of compositions for a thermoelectric material system considers a variety of relevant factors, parameters and the like in order to determine which material systems should be considered and / or which range of compositions should be studied in more detail. A thermoelectric material exhibiting a dimensionless high figure of merit (ZT) needs to possess a high Seebeck coefficient (S) for high voltage generation, a low electrical resistivity (p) to minimize Ohmic losses and a low thermal conductivity (k) to minimize heat conduction.

[0031]The relationship between ZT, S, p, and k can be expressed as:

ZT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com