Such a theoretically perfect diamond lattice is thermodynamically impossible to attain.

In reality, it is practically difficult to even approach a level of perfection which would be possible to achieve in theory when taking into account thermodynamic considerations.

As such, it should be apparent that all diamond materials contain a significant number of defects.

Such defects may come in the form of impurities.

Additionally, defects within diamond materials also include crystallographic deviations from the perfect diamond lattice structure in the form of point defects such as vacancies and interstitials and extended defects such as various forms of

dislocation defects.

Defects within diamond materials significantly alter the properties of the materials.

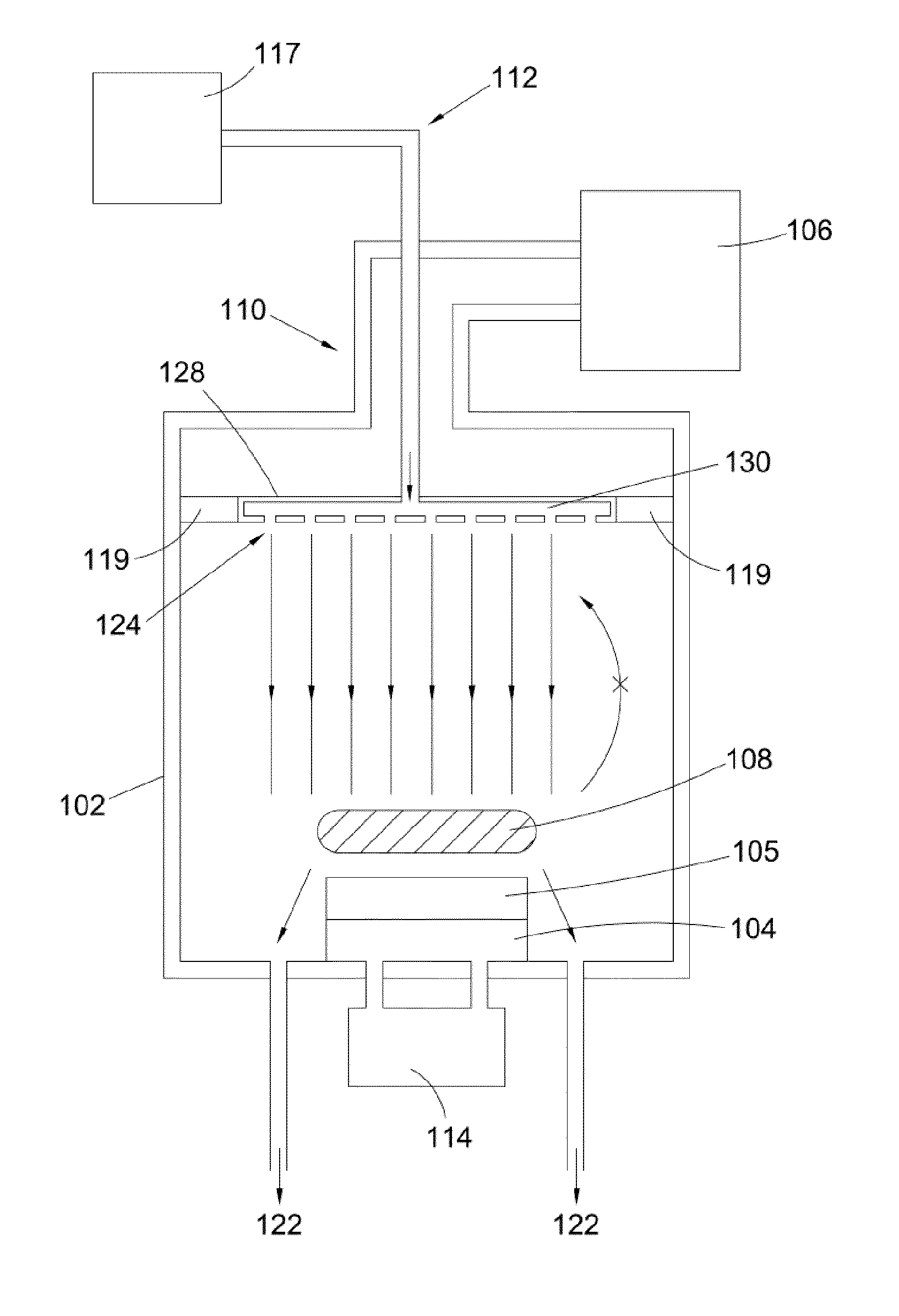

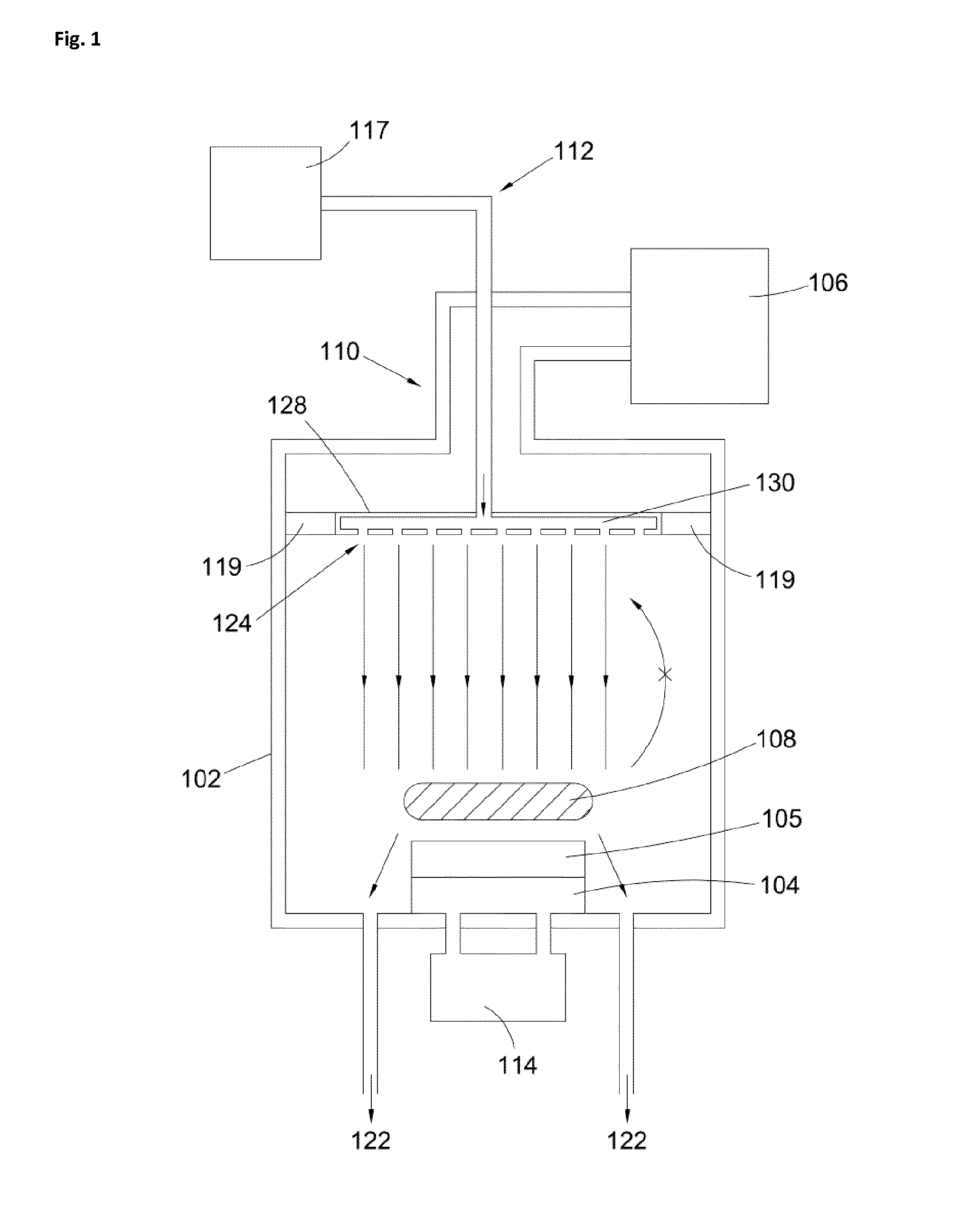

Furthermore, the nature of the substrate material and the growth conditions affect the type and distribution of defects incorporated into the CVD synthetic diamond material during growth.

However, in such applications impurities can interact with quantum spin defects within the diamond lattice structure reducing their decoherence time and thus reducing their sensitivity and / or reducing the time during which quantum

processing applications can be performed.

Nitrogen is one of the most important dopants in CVD diamond

material synthesis as it has been found that providing

nitrogen in the CVD process gas increases the growth rate of the material and can also affect the formation of crystallographic defects such as dislocations.

A problem with synthesizing low defect, high purity single

crystal CVD synthetic diamond material is that such material has a very low growth rate and is thus

time consuming and expensive to manufacture.

Furthermore, due to the

extended time periods required to obtain a desired thickness of such material at low growth rates, the growth process must be very precisely controlled over

extended time periods and this can be difficult to achieve in practice resulting in reduced yields.

However, while single

crystal CVD synthetic diamond material according to this process is suitable for many optical applications, the concentration of

nitrogen incorporated into the material is such that the material is not ideally suited for certain high-end optical applications and certain other applications such as electronic,

radiation detector, and quantum sensing and

processing applications which require higher purity material and a CVD growth process in which

nitrogen is essentially excluded.

Furthermore, even for applications which are not detrimentally affected by the presence of a low and controlled concentration of nitrogen in the single crystal CVD synthetic diamond material, it can be difficult to obtain consistent and reproducible optical properties, such as low absorption, utilizing a low and controlled nitrogen addition.

However, such a

plasma focussing

route is not suitable for achieving high power densities across relatively large growth areas to enhance volume growth rate.

A decrease in

power density also leads to a decrease in the quality of single crystal CVD diamond material which is synthesized.

One problem with prior art methodologies is how to achieve very high purity single crystal CVD synthetic diamond material, suitable for certain high-end optical applications and certain other applications such as electronic,

radiation detector, and quantum sensing and

processing applications, at increased volume growth rates (e.g. over a plurality of

single crystal diamond growth substrates) while avoiding the addition of nitrogen to enhance growth rates.

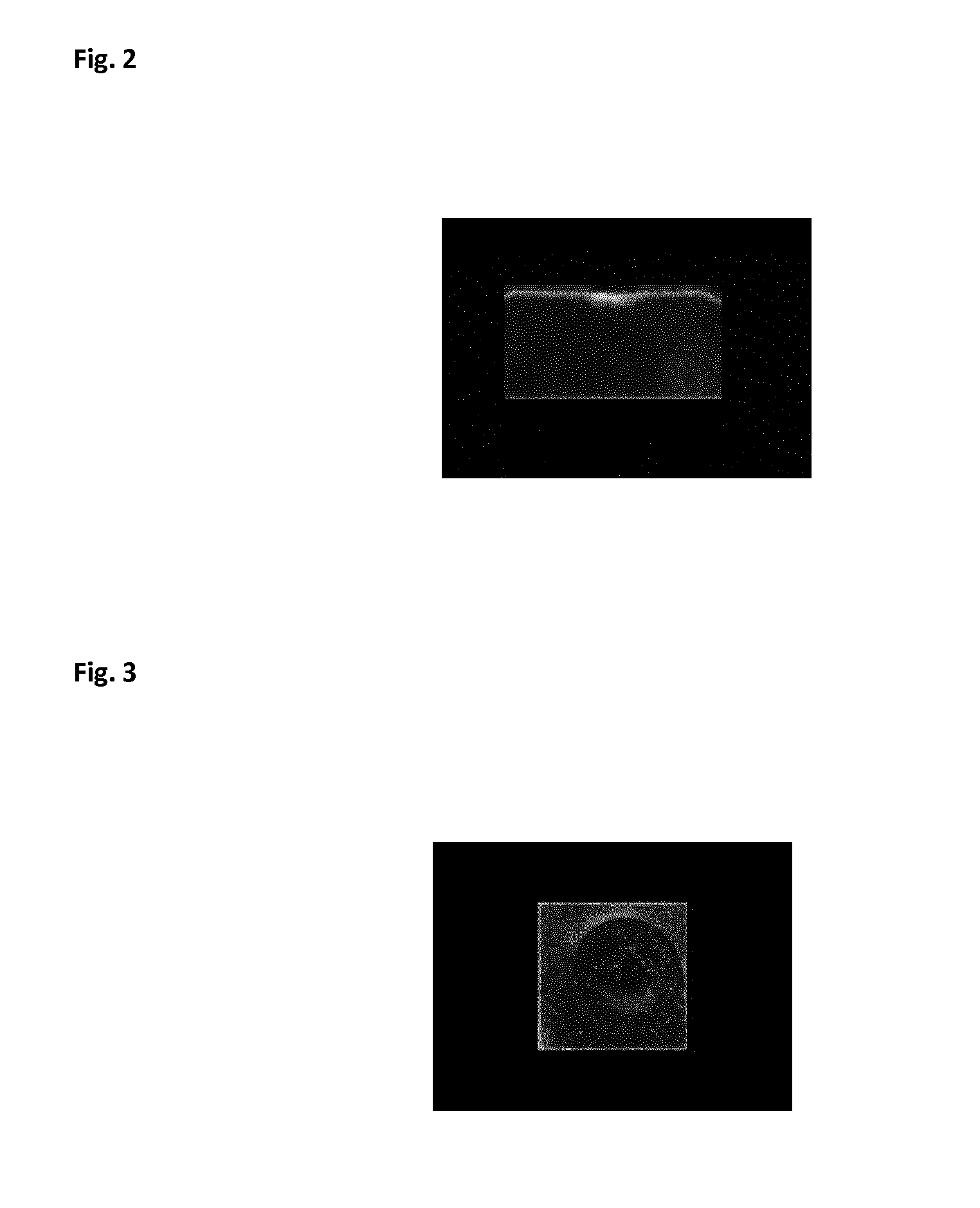

However, due to the polycrystalline nature of such wafers their functional properties are generally not as good as high quality

single crystal diamond materials.

However, it is difficult to achieve good quality single crystal diamond growth over interface regions between the tiled substrates and to date it has been required to introduce significant portions of nitrogen into the synthesis

atmosphere to achieve reasonable intergrowth of single crystal diamond material grown over tiled substrates.

This results in a significant quantity of nitrogen being incorporated into the single crystal CVD diamond

wafer grown over the tiled array of substrates detrimentally affecting the mechanical, optical, thermal, electronic, and / or quantum properties for end applications.

Login to View More

Login to View More