Method for improving the coking resistance of a lubricating composition

a technology of lubricating composition and coking resistance, which is applied in the field of lubricating compositions, can solve the problems of thermal resistance and coking resistance, the defect of lubricating the roller bearing of the turbine of the engine, and the high reduction of the flow rate of oil circulation, so as to achieve quick test consumption and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

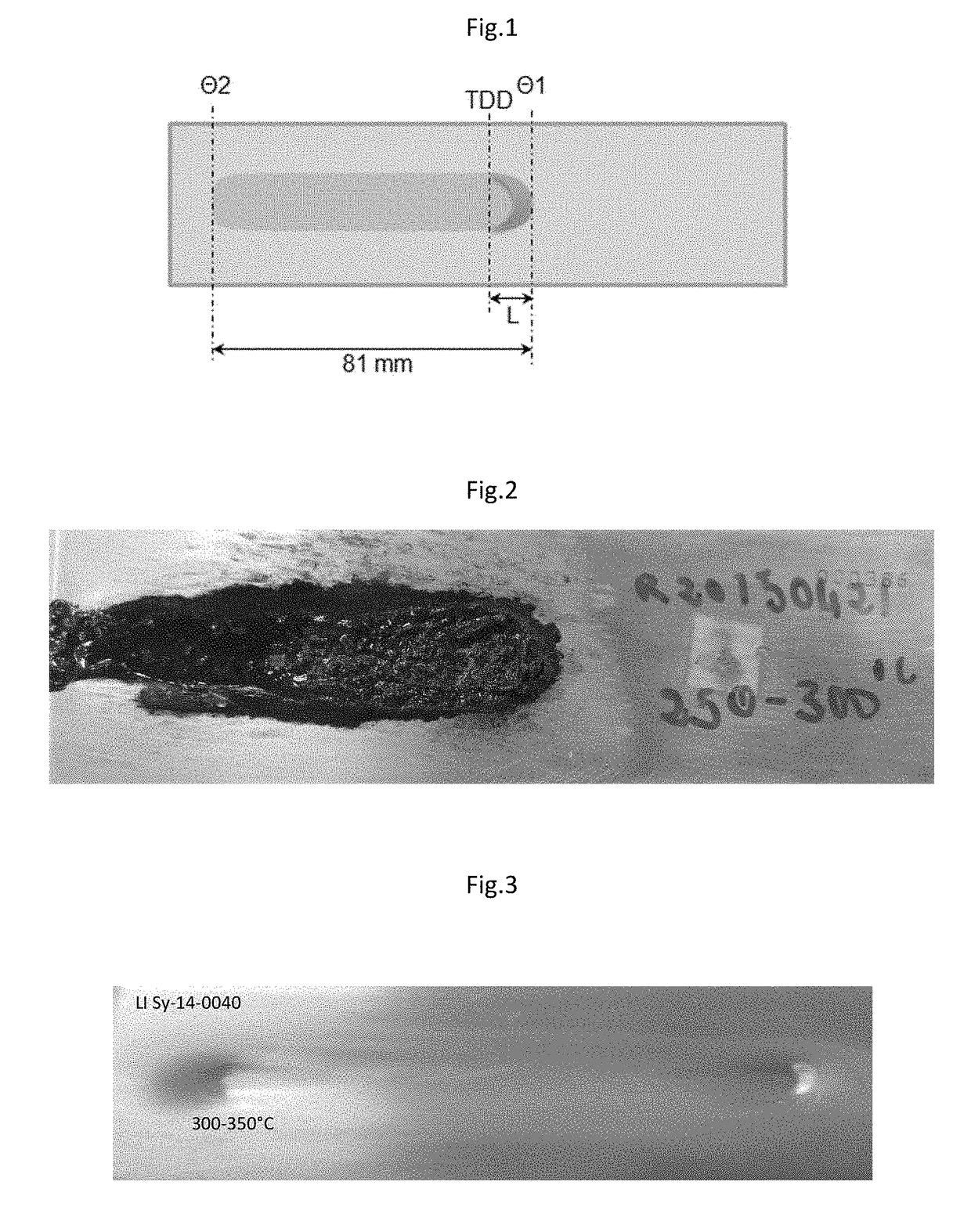

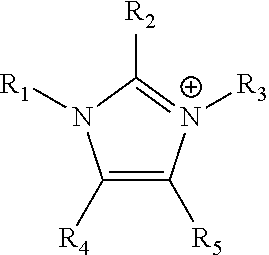

[0194]The applicant has shown by the following experimental testings that a precise combination of anions and cations as well as of their substituents make it possible to form an ionic liquid or a mixture of ionic liquids having an excellent resistance to coking for thin films.

[0195]The applicant has also tested the ionic liquids disclosed in the prior art cited further up. In a surprising manner, it has been stated that most of the ionic liquids as thin films degrade very quickly as the tables hereinafter show, notwithstanding their remarkable thermal stability which goes along with their very good results in TGA.

[0196]A. Experimental Protocol

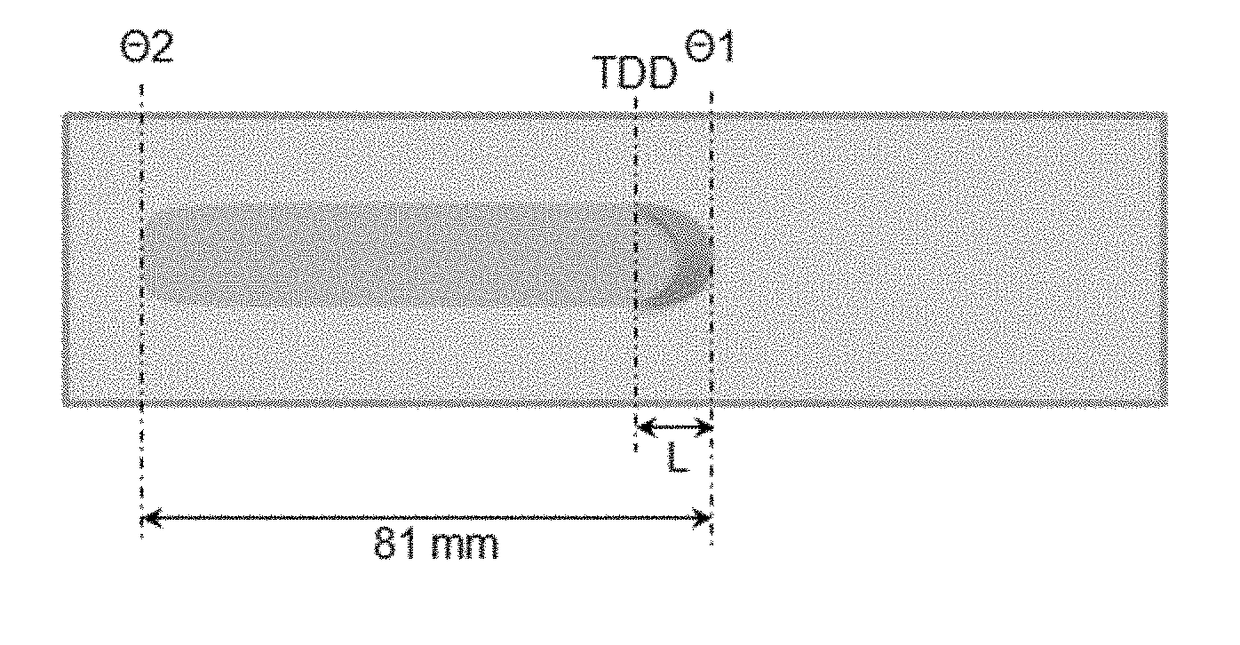

[0197]The conditions of the experimental testing are as follows:[0198]0.6 ml of oil without anti-foam[0199]duration: 90 min[0200]plate made of an aluminum alloy tilted by 1.5%+ / −0.05% toward the hot point which is situated at the lower point comprising a trough[0201]temperature gradient here generally from 250° C. to 300° C. (or more, for exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com