Subsea carrier

a technology for submerged ships and ships, applied in waterborne vessels, special-purpose vessels, vessel parts, etc., can solve the problems of significantly reducing design requirements, reduce operating costs, reduce buoyancy, and reduce drag. effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

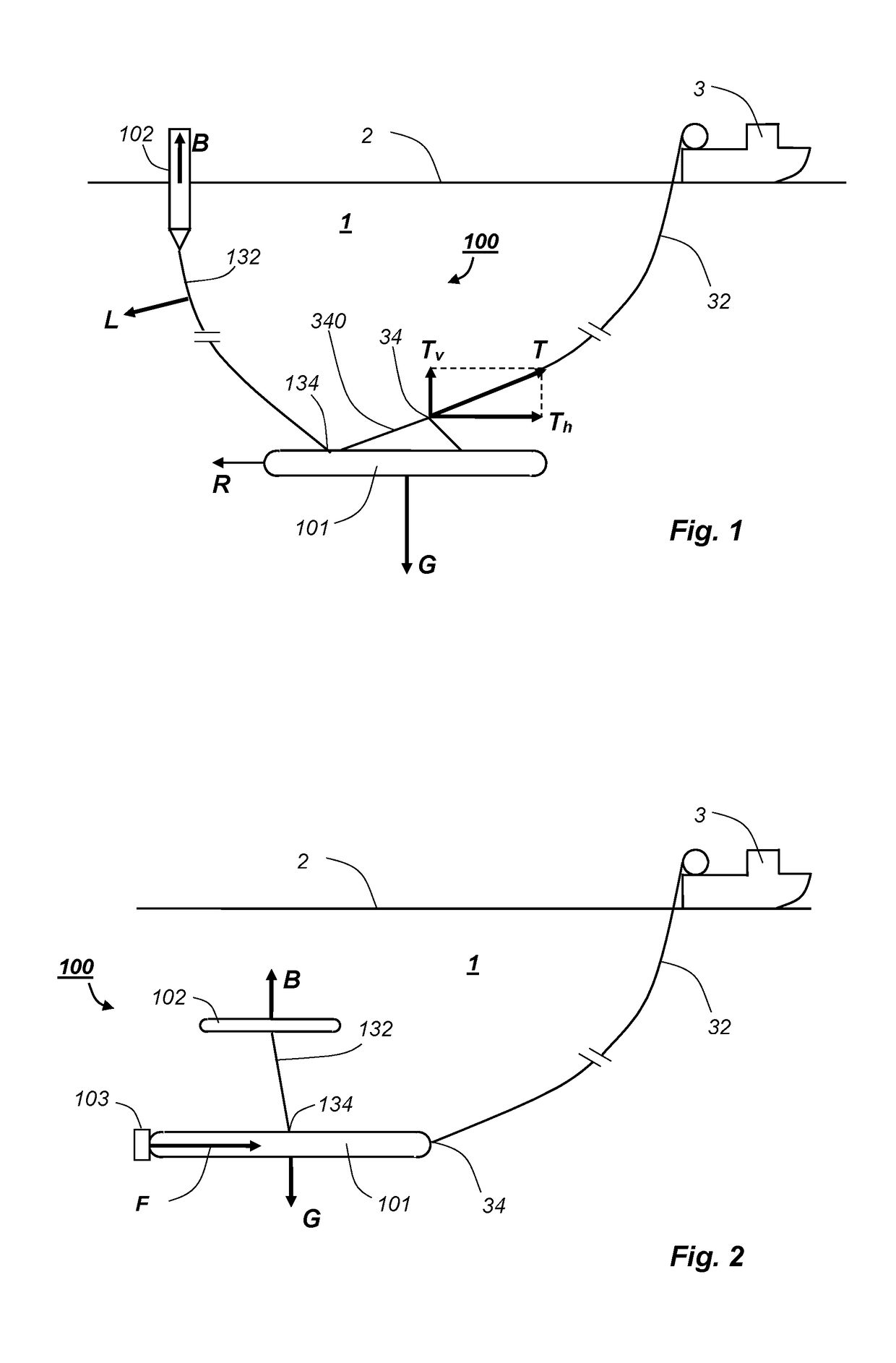

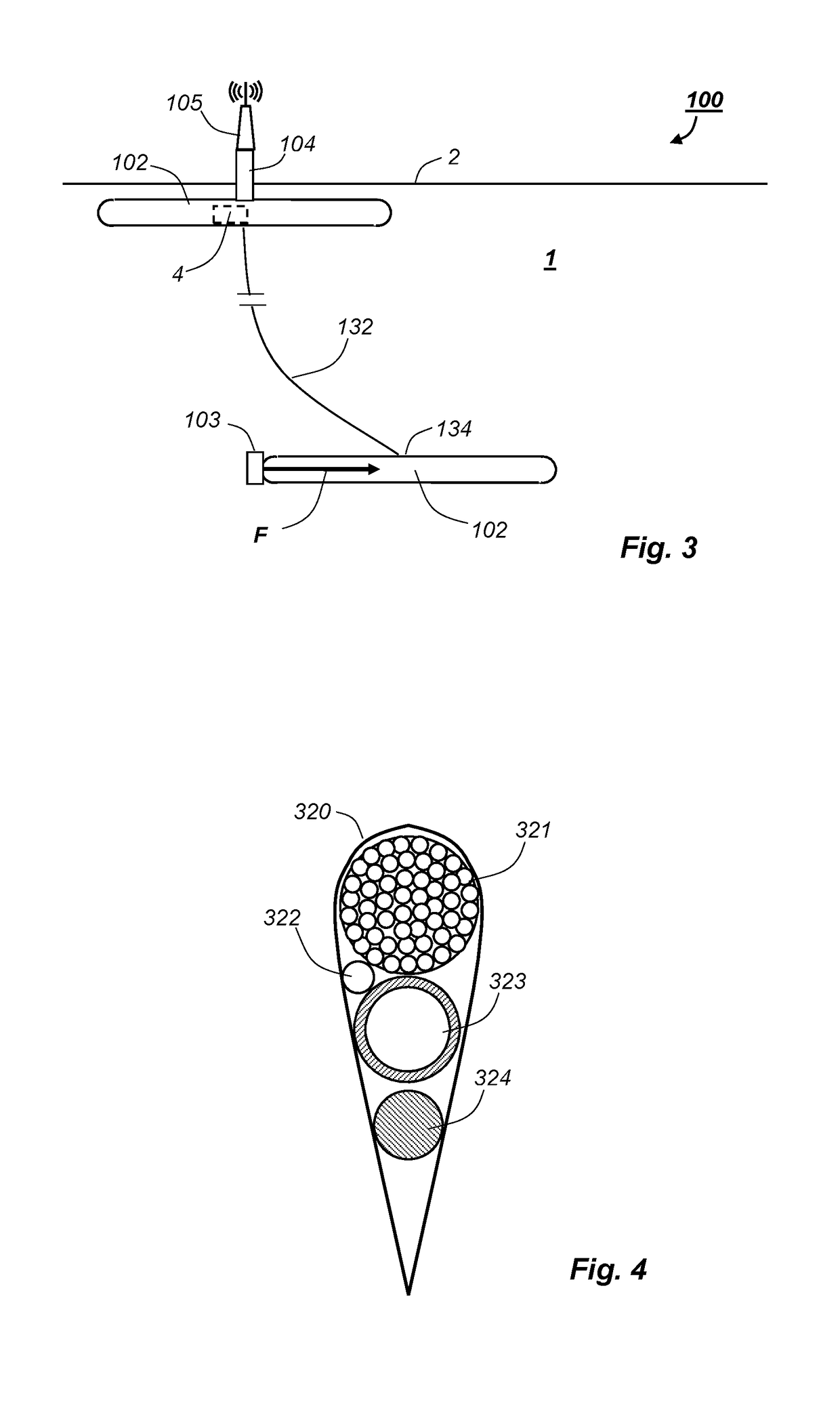

[0058]The drawings are schematic and intended to illustrate the principles of the invention. Hence, the drawings are not necessarily to scale, and numerous details are omitted for clarity.

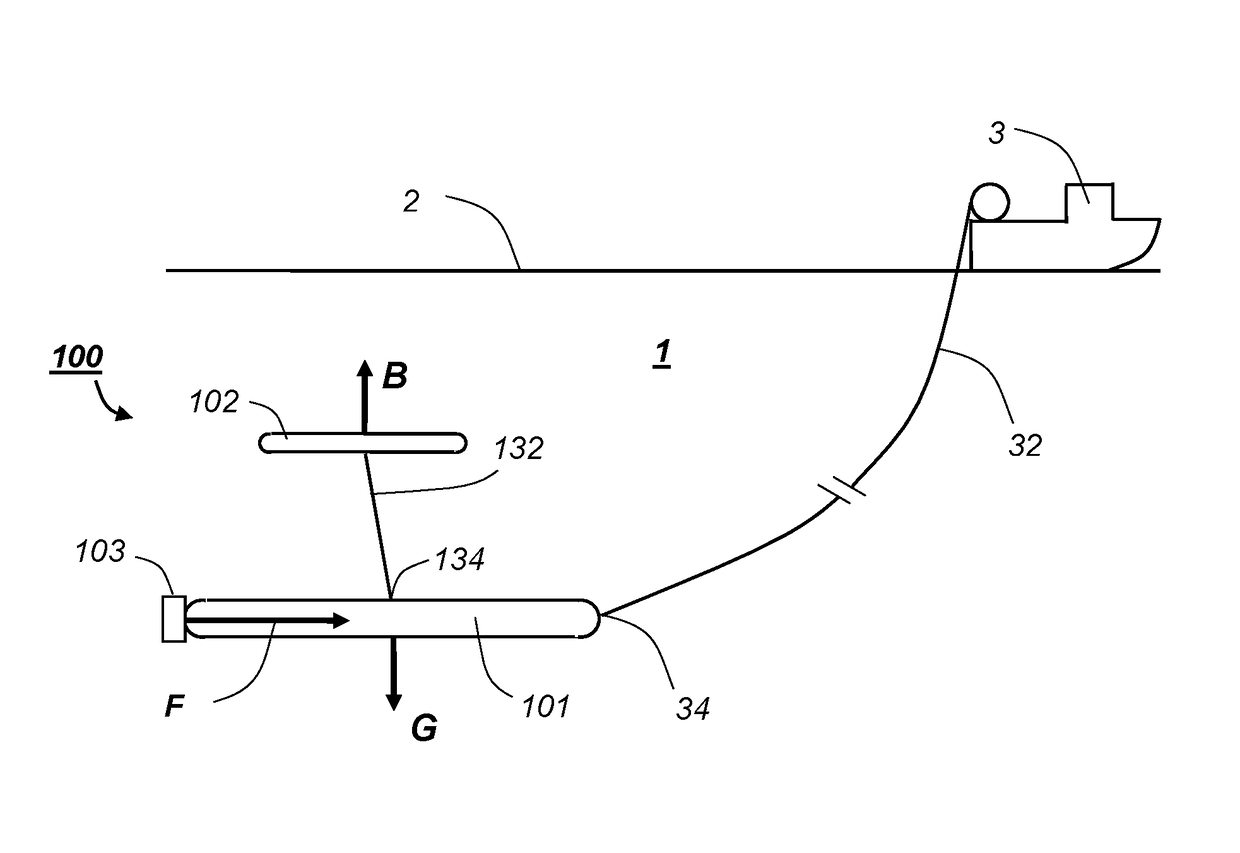

[0059]An important aim of the invention is to carry a cargo of fluid, e.g. hydrocarbons, from a loading point to an unloading point along a predefined path as inexpensively as possible. In the present context, this implies keeping an elongated main body 101 aligned with a predetermined path in three dimensions fixed to the Earth, e.g. longitude, latitude and depth, by controlling local coordinates fixed to the main body 101, e.g. roll, pitch and yaw as illustrated with reference to FIG. 9.

[0060]FIG. 1 illustrates a first embodiment of a system according to the invention, comprising a subsea carrier 100 partly submerged in a body of water 1 having a surface 2. A towing vessel 3 on the surface 2 tows the subsea carrier 100 by means of a towing cable 32, in the claims expressed as a control cable with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com