Contained growing space and environmental control system

a technology of environmental control and growing space, which is applied in the direction of greenhouse cultivation, lighting and heating equipment, heating types, etc., can solve the problems of reducing crop yield, affecting product quality, and excessive heat, so as to reduce the energy reduce the heat content of recirculating air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0065]In some applications, the humidity level in the closed agricultural system requires more extensive dehumidification than normal. As shown in FIG. 6, a second desiccant wheel is installed downstream of the recirculation fans and condensing coil. The enthalpy wheel is replaced with a heat wheel (sensible heat-only wheel, no desiccant). A condensing coil or a natural gas burner acts as regeneration heat for the latent heat-only wheel. As the desiccant wheel rotates from one air stream to the other it adsorbs the moisture from the recirculation air. That moisture is then released to the outside air stream. To aid in that release, regeneration heat (condensing coil heat and / or optional natural gas burner) is applied to the air entering the wheel in the outside air stream. An additional set of temperature and relative humidity sensors are installed downstream of the desiccant wheel. The control system varies the speed of the desiccant wheel to meet the user defined relative humidity...

example 2

[0066]The efficiency of the air handling system depends on the outside air temperature and humidity. When conditions are favorable (cooler dryer weather), the system is capable of transferring the heat and humidity of the recirculation air through the enthalpy wheel to the cooler and dryer outside air. As indicated in the flow diagram shown in FIG. 7, 57° F. outside air with 40.7 grains of moisture is coming into the unit and into the enthalpy wheel. The resulting recirculation air temperature and grain level off the wheel (60° F. / 45.1 grains) to provide 100% of the required heating and dehumidification.

example 3

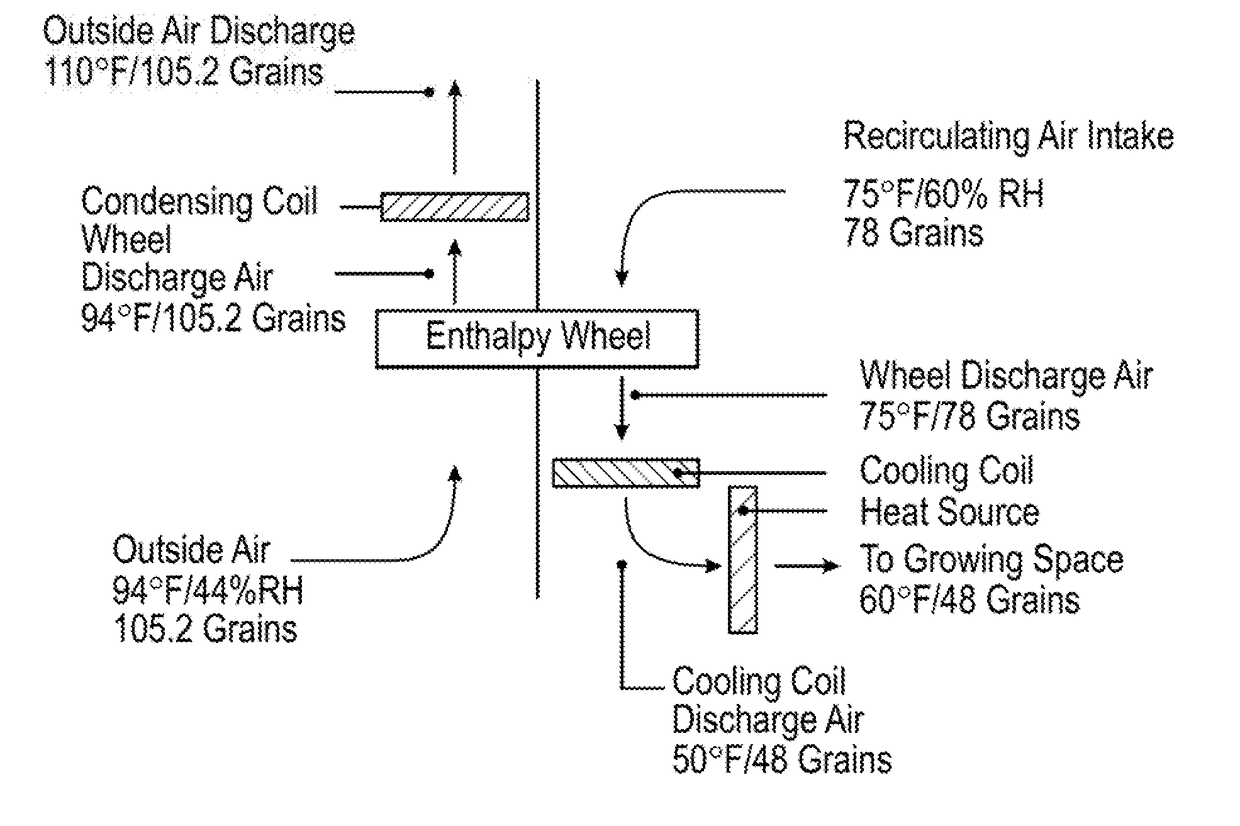

[0067]As the outside air temperature and humidity go up, the enthalpy wheel can still provide value by “pre-conditioning” the recirculation air before the cooling coil. In the flow diagram shown in FIG. 8, 57° F. outside air with 60.6 grains is entering the air handling unit and the enthalpy wheel. The resulting recirculation air temperature and grain level off the wheel (60° F. / 63.2 Grains) is sufficient to cool the recirculating air, but it is not sufficient to remove the moisture from the recirculating air. As a result the air handling unit control system shall enable the mechanical cooling to remove the additional grains of moisture from the recirculation air, down to the user defined set point of 48 grains. In order to remove the moisture the cooling coil must over cool the air, 50° F. The over cooled air could potentially over cool the recirculating air, therefore the air handling unit control system shall enable the heat source to heat the recirculating air to the user define...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com