Compact, modular, integral pump or turbine with coaxial fluid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 200

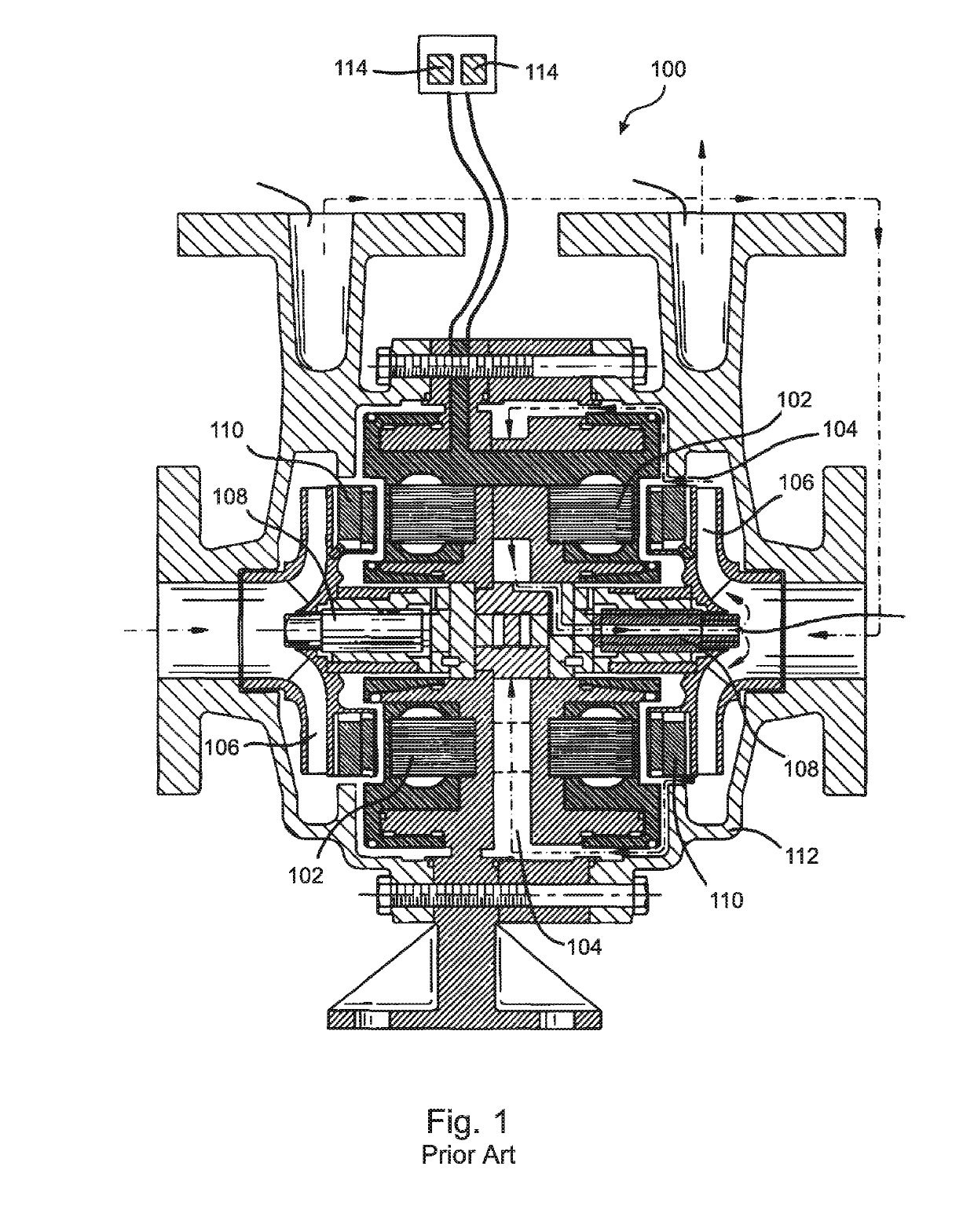

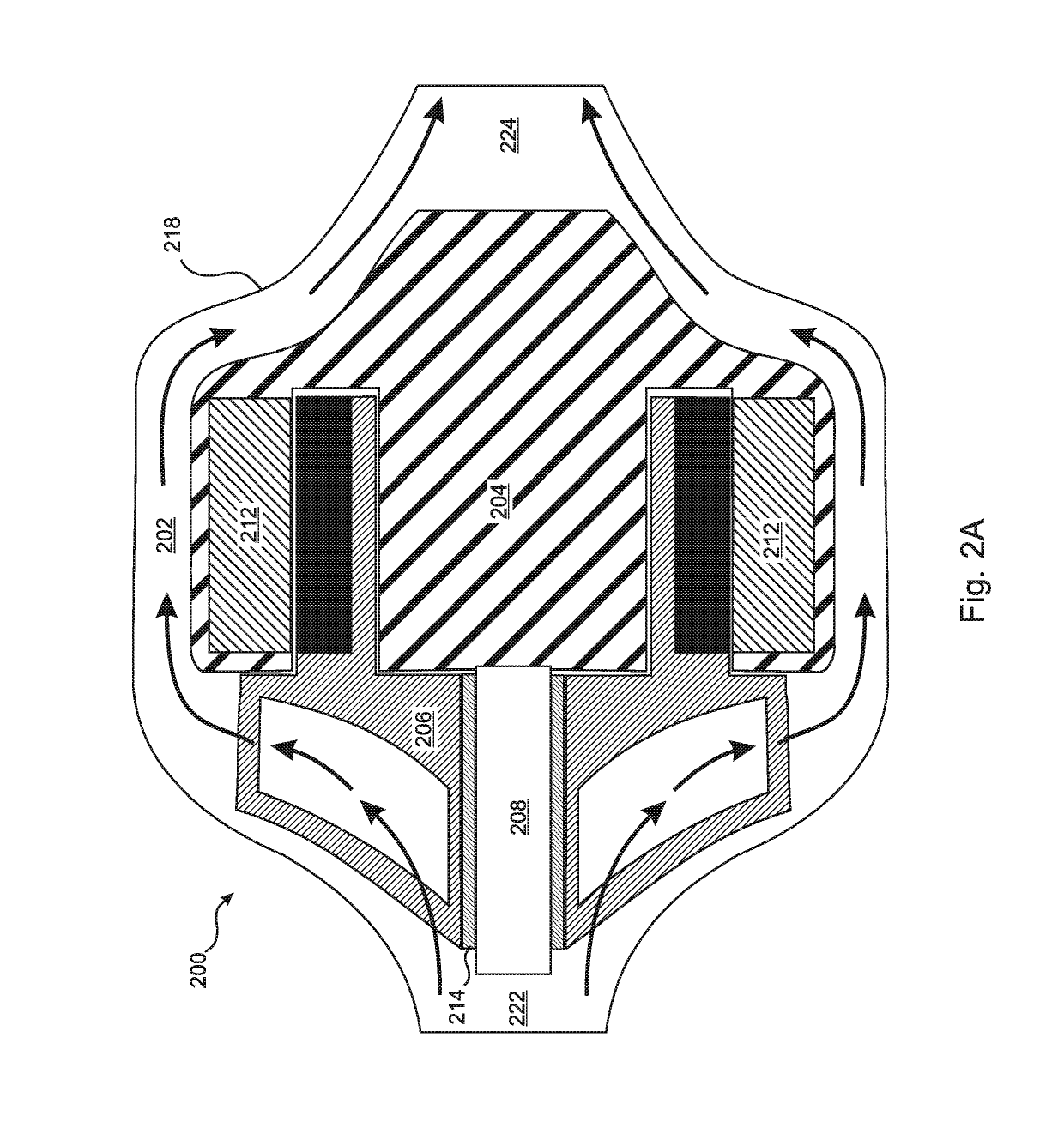

[0067]The present invention is a “sealless” motor pump or sealless generator turbine that is configured as a module having a “concentric” flow design. As an example, a pump embodiment 200 of the present invention is illustrated in FIG. 2A. It can be seen in the figures that the housing 204 of the motor coils is surrounded by the housing 218 of the module, forming an annular space 202 therebetween. According to the present invention, the working fluid is distributed symmetrically about the annular space 202, either among a plurality of substantially identical flow passages or through a single annular flow passage. In the embodiment of FIG. 4A, the annular space 202 serves as an annular flow passage 202 through which the working fluid flows from the inlet 222 to the outlet 224.

[0068]In the embodiment of FIG. 2A, the annular flow passage 202 is in direct thermal contact with the housing 204 of the motor coils 212. This configuration is suitable for applications where the working fluid ...

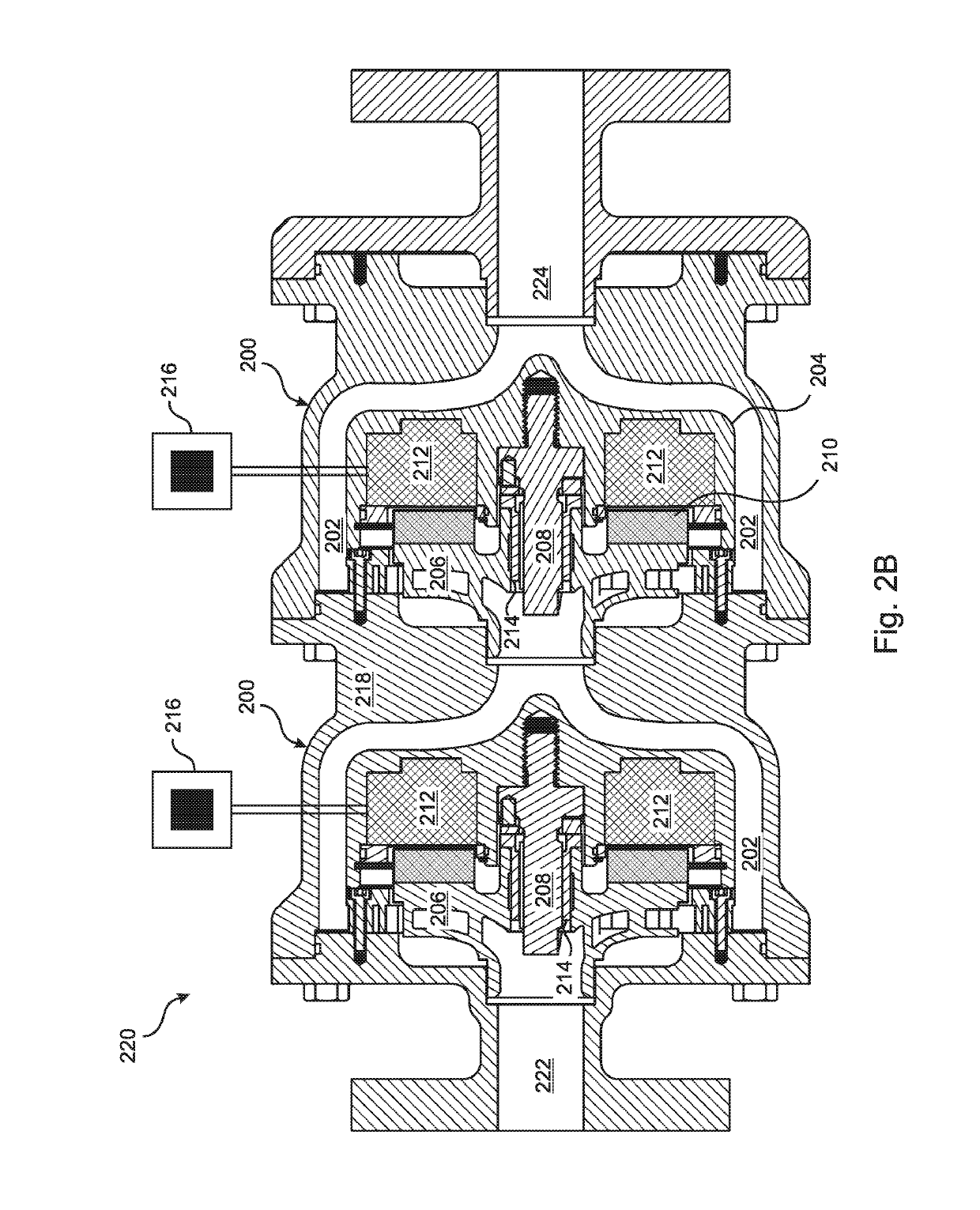

embodiment 220

[0070]More specifically, FIG. 2B illustrates a two-stage pump embodiment 220 wherein a central axis of the motor 212 in each stage 200 is substantially collinear with the stationary shaft 208 about which the rotor 206 is rotated, such that the process fluid from the rotor 206 flows axially over the motor housing 204 through the annular flow passage 202 formed between the motor housing 204 and the pump coil housing 218 in each stage 200. While only two stages 200 are shown in FIG. 2B for convenience of illustration, it will be understood that embodiments are extendable to an arbitrary number of pump stages 200.

[0071]In some multi-stage embodiments, the rotor 206 in each stage 200 is independently driven, such that the rotor speed of each stage 200 can be separately controlled. For example, a separate variable frequency drive (“VFD”) 216 can be dedicated to the control of each stage 200 of the pump.

[0072]In the embodiment of FIG. 2B, in each stage 200 of the pump 220 a plurality of pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com