(METH)acrylic resin and method for controlling strain thereof

- Summary

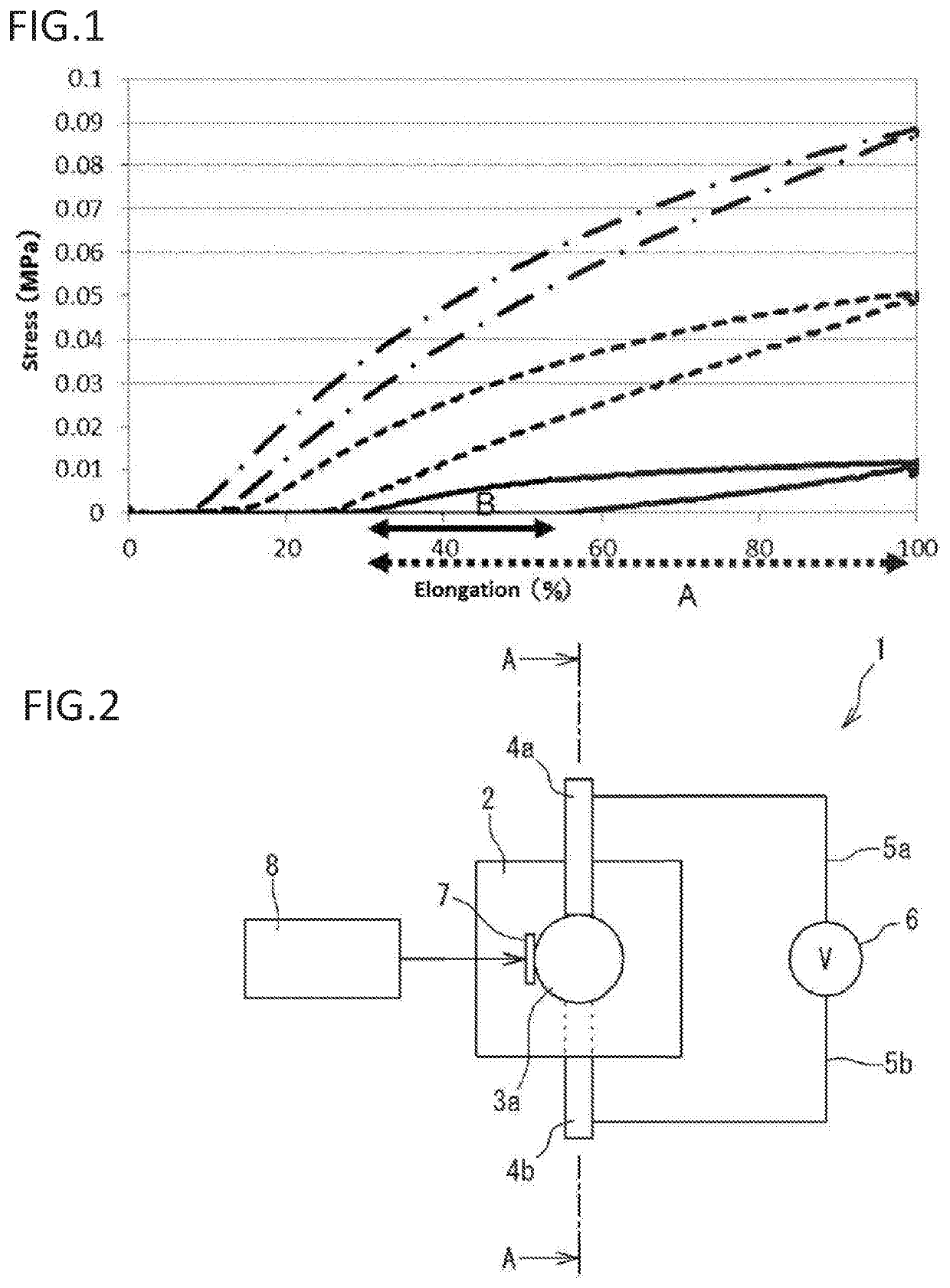

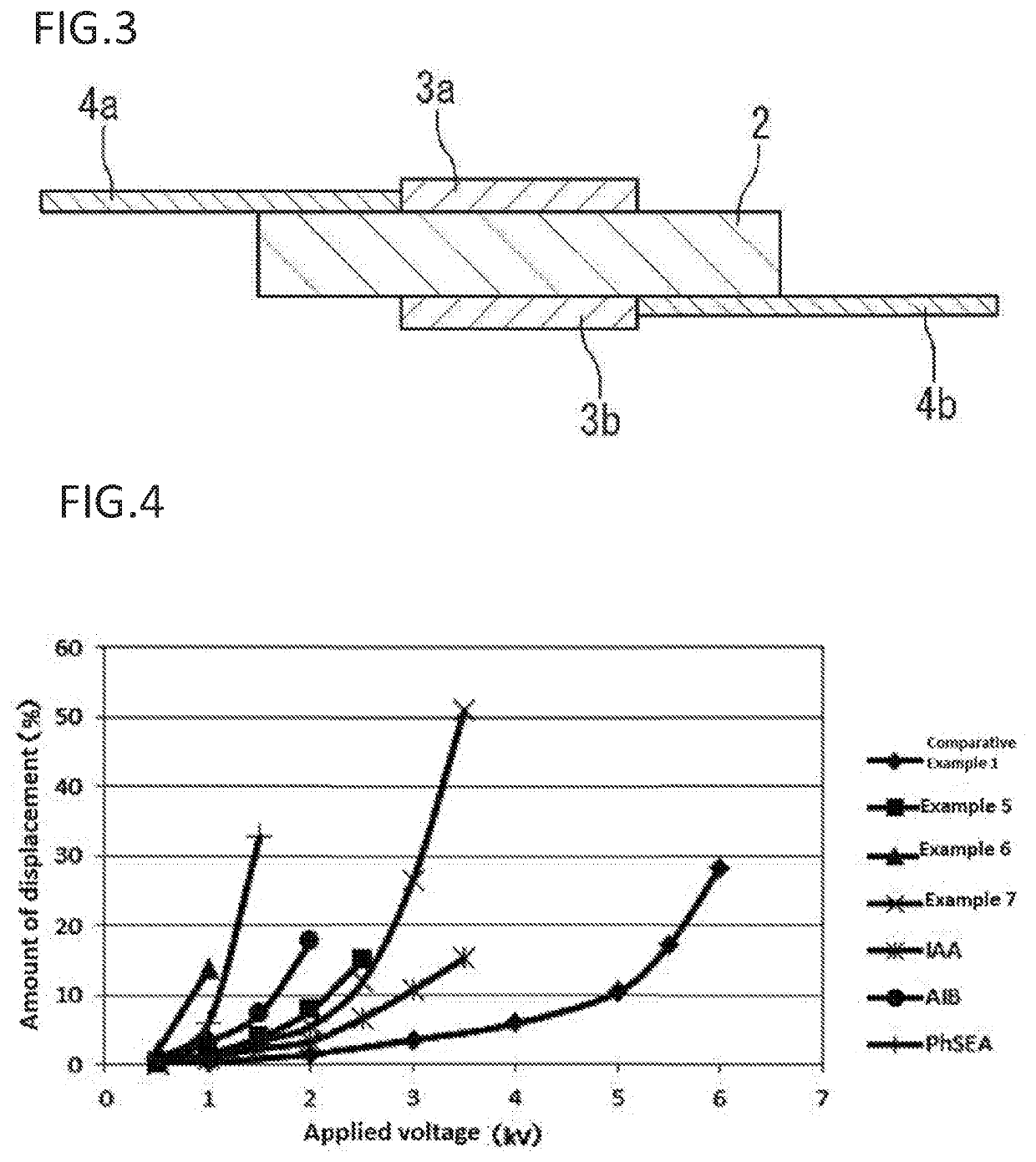

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

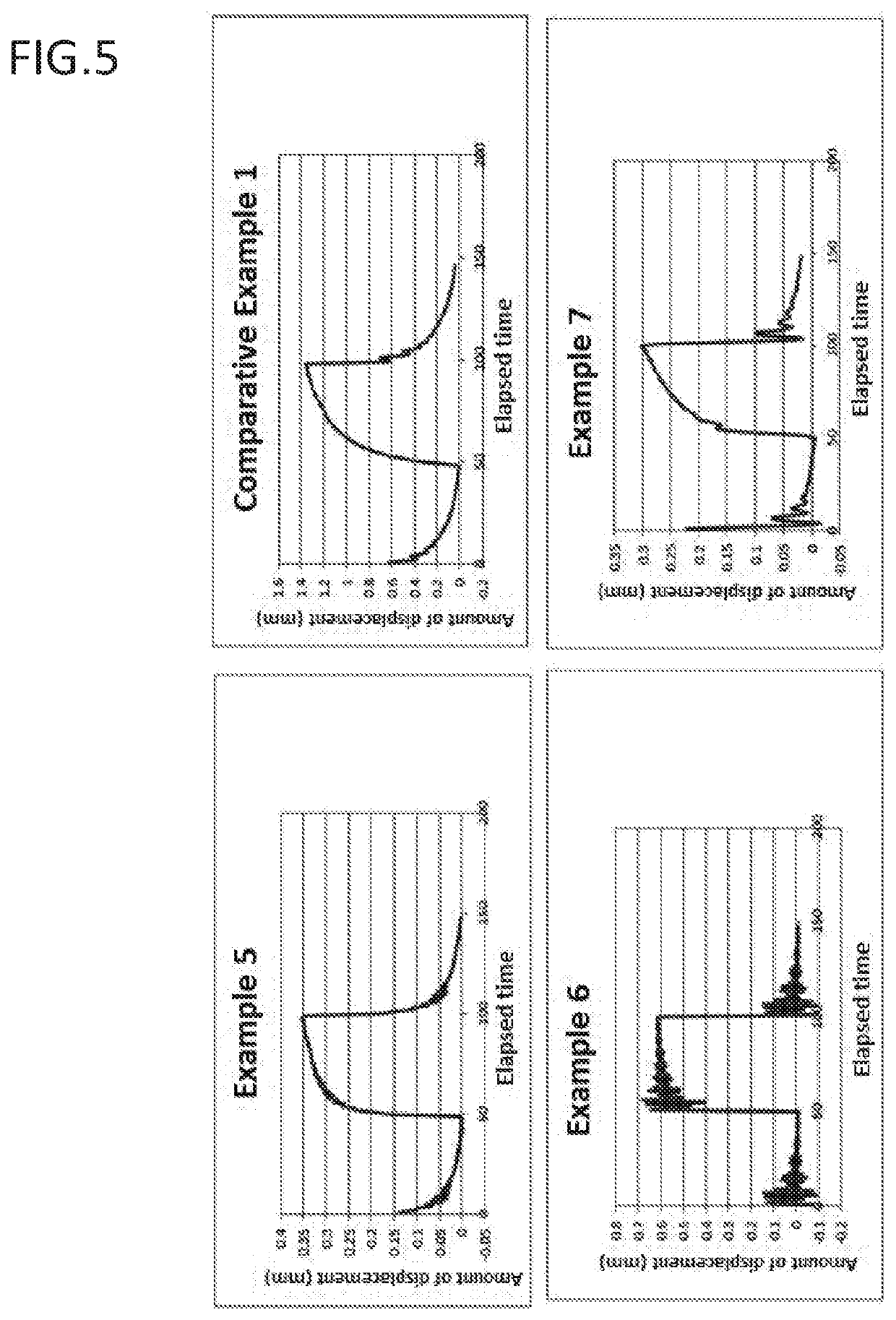

Examples

example 1

nt of Illuminance of Ultraviolet Ray Resulting in a Given Strain

[0445]Illuminance of an ultraviolet ray for producing a polymer with a given strain is determined by the following procedure.

[0446][Derivation of Relationship Between Strain-Illuminance]

[0447]1) Provision of Starting Material Monomer

[0448]A suitable monomer is selected for each specific example for Example 2 and Examples thereafter. For example, for the (meth)acrylic polymer in Example 2, a monomer component comprising a polymerization initiator is provided by mixing 7.03 g of ethyl acrylate, 0.17 g of diethylene glycol dimethacrylate, and 0.0042 g of 2,4,6-trimethylbenzoyl diphenylphosphine oxide [BASF, product name: Irgacure TPO] as the polymerization initiator.

[0449]2) Irradiation of Ultraviolet Ray with Specific Illuminance onto the Starting Material Monomer for Polymerization

[0450]Once an appropriate monomer component is obtained for each Example, an ultraviolet ray is irradiated thereon. For example, for Example 2...

example 2

[0463]Acryl Resin (1)

[0464]A monomer component comprising a polymerization initiator was obtained by mixing 7.03 g of ethyl acrylate, 0.17 g of diethylene glycol dimethacrylate, and 0.0042 g of 2,4,6-trimethylbenzoyl diphenylphosphine oxide [BASF, product name: Irgacure TPO] as the polymerization initiator.

[0465]A (meth)acrylic elastomer was obtained by injecting the resulting monomer component into a transparent glass mold with a release film (vertical: 100 mm, horizontal: 100 mm, depth: 0.3 mm), and then irradiating an ultraviolet ray on the monomer component so that the amount of irradiated rays was 0.5 to 50 mW / cm2 to subject the monomer component to bulk polymerization. The following Table 1 shows the measurement results.

example 3

[0466]Acryl Resin (2)

[0467]A monomer component comprising a polymerization initiator was obtained by mixing 30.01 g of ethyl acrylate, 0.35 g of 2-hydroxyethyl acrylate, and 0.038 g of 2,4,6-trimethylbenzoyl diphenylphosphine oxide [BASF, product name: Irgacure TPO] as the polymerization initiator.

[0468]A (meth)acrylic elastomer was obtained by injecting the resulting monomer component into a transparent glass mold with a release film (vertical: 100 mm, horizontal: 100 mm, depth: 2 mm), and then irradiating an ultraviolet ray on the monomer component so that the amount of irradiated rays was 0.5 to 50 mW / cm2 to subject the monomer component to bulk polymerization. The following Table 2 shows the measurement results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com