Process for forming and acoustically connecting structures on a substrate

a technology of acoustic connection and substrate, which is applied in the field of microelectromechanical systems (mems) devices, can solve the problems of slow forming of vents and small vent diameter, and achieve the effects of reducing the thickness of the back side of the substrate, reducing the thickness, and reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

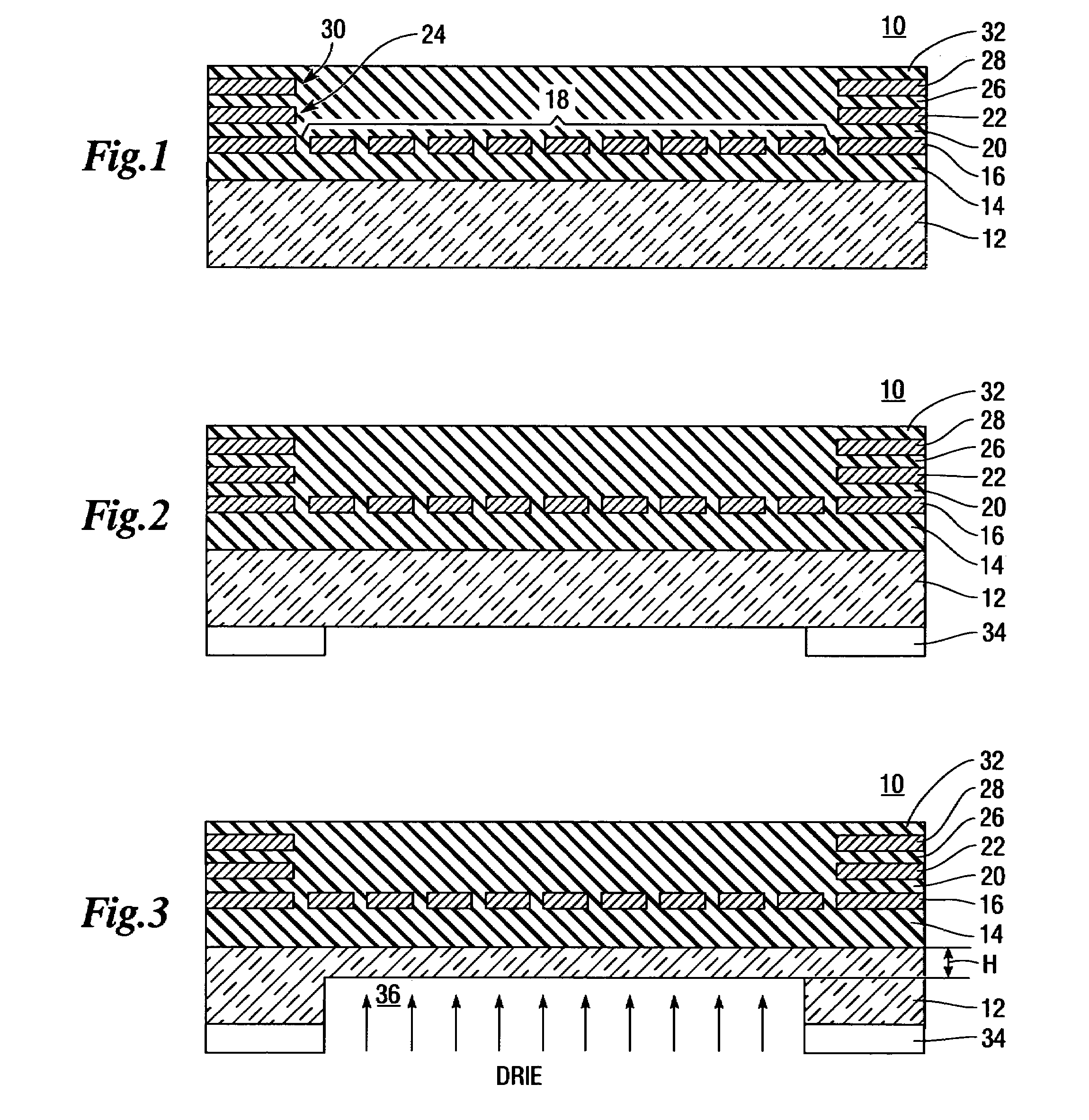

[0026]A first embodiment of the present invention is illustrated in conjunction with FIGS. 1–9. In FIG. 1, a die 10 is received from a CMOS foundry. At the CMOS foundry, a silicon substrate 12 has been processed so as to form alternating layers of, for example, a dielectric material and a metal. The die 10 illustrated in FIG. 1 has a first layer of dielectric material 14 carrying a first metal layer 16. The first metal layer 16 has been patterned such that a portion thereof forms a micro-machined mesh 18. Formed on the first metal layer 16 is a second layer of dielectric 20. The second layer of dielectric 20 carries a second metal layer 22 which has been patterned to have an opening 24 formed therein. The second metal layer 22 carries a third layer of dielectric 26. The third layer of dielectric 26 carries a third layer of metal 28 which has been patterned to have an opening 30 formed therein. A top layer of dielectric 32 is formed on top of the third metal layer 28.

[0027]The presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Anisotropy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com