Conductive adhesive

a conductive adhesive and paste-like technology, applied in the direction of non-macromolecular adhesive additives, conductors, metal/alloy conductors, etc., can solve the problems of lowering the long-term reliability of in-vehicle electronic devices and modules, lowering the connection strength, and lowering the adhesive strength between the metal surface and the cured conductive product. , to achieve the effect of lowering the adhesive strength, excelling in the adhesive strength to the metal surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0062]The present invention will be more specifically illustrated hereunder referring to examples. Although these examples are certain examples of the best modes for carrying out the present invention, the scope of the present invention is in no way limited to these specific examples.

[0063]For evaluating the properties and performances of paste-like conductive adhesives (conductive paste) disclosed in the following examples and comparative examples, each evaluation item was measured using the below-described procedures and conditions.

I. Resin Properties of Epoxy Thermosetting Resin per se used in Paste-like Conductive Adhesives

[0064][Glass Transition Temperature (Tg)]

[0065]A cured resin product of the epoxy thermosetting resin per se is prepared under curing conditions of 150° C. and 60 minutes. For the obtained cured resin product, the glass transition temperature (Tg) is measured using a DSC (differential scanning calorimeter) under a condition that temperature elevation rate is s...

examples 1 to 5

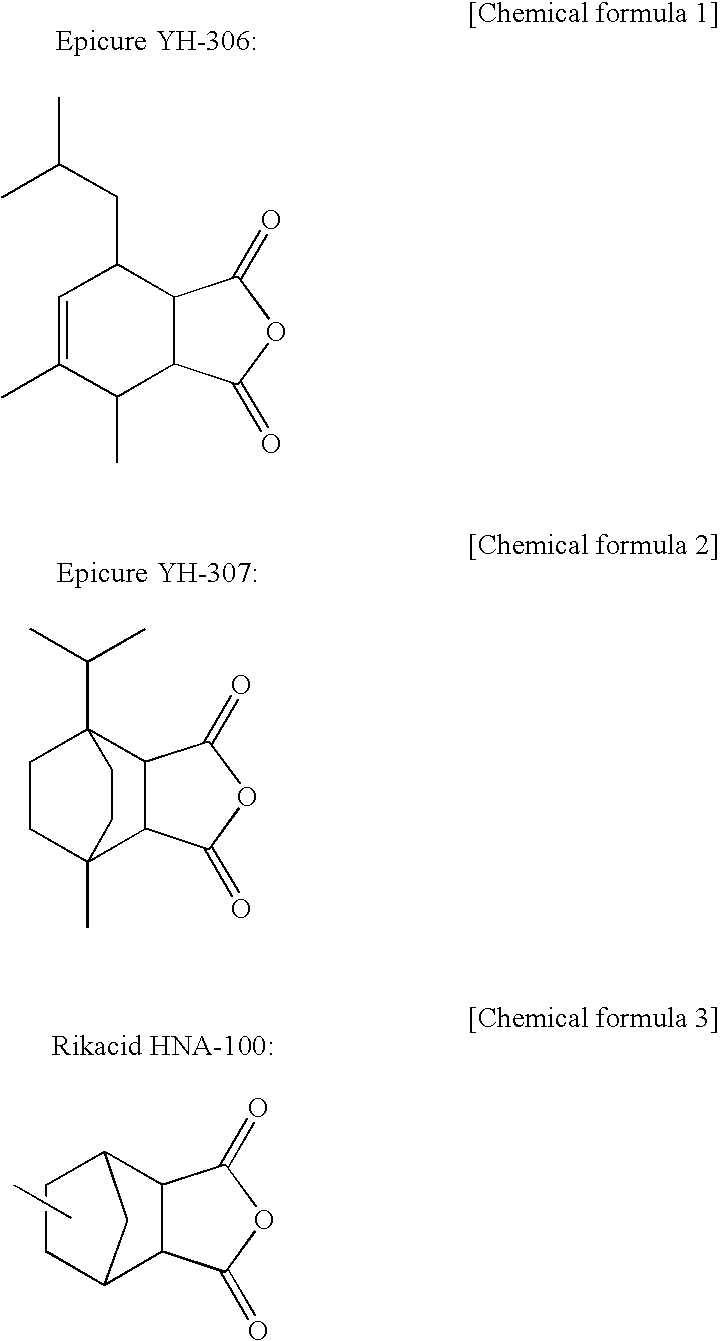

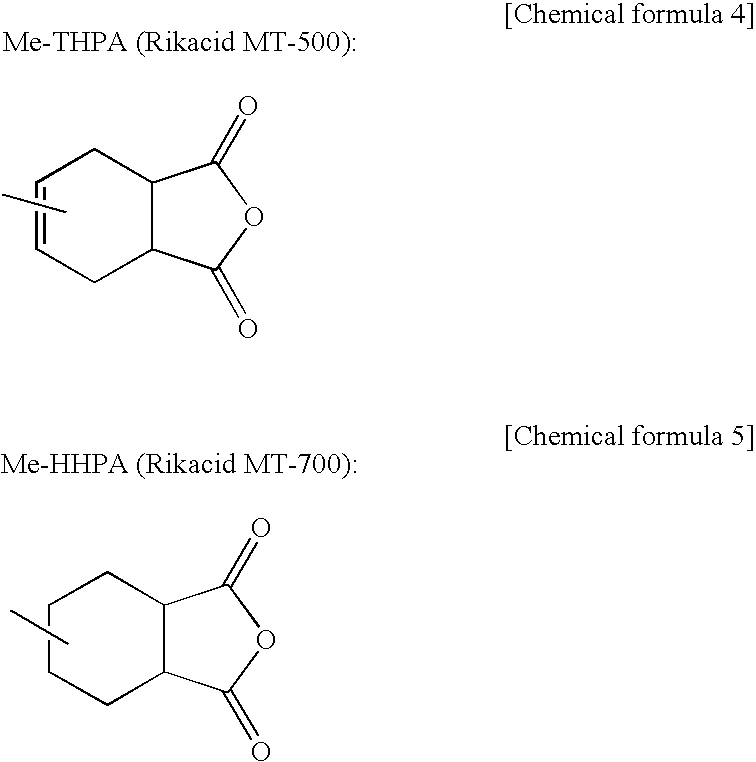

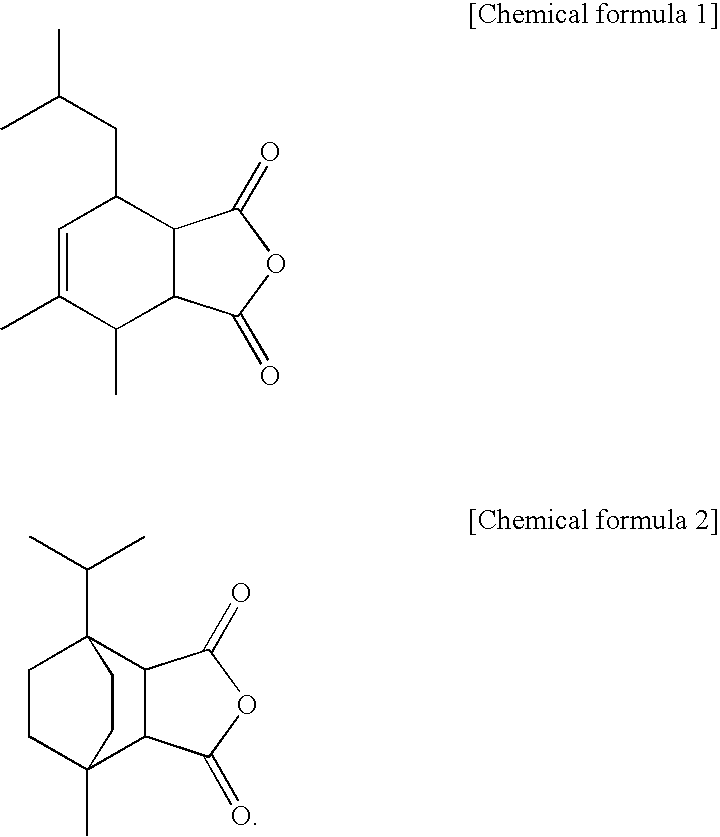

[0099]Spherical silver powder having an average particle diameter of 3 μm was employed as the metal powder for the conductive medium to be blended in the conductive paste; and the spherical silver powder was evenly dispersed by stirring in the one-component epoxy thermosetting resin component to prepare the conductive paste of the compounding composition listed in Table 1.

[0100]In said one-component epoxy thermosetting resin component,

[0101]used for the epoxy resin component thereof were

[0102]Epiclon HP-4032D (product of JER; 1,6-dihydroxynaphthalene diglycidyl ether, epoxy equivalent: 142) as the epoxy compound having naphthalene skeletons;

[0103]THATGE (1,2,10-trihydroxyanthracene triglycidyl ether, epoxy equivalent: 142) as the trifunctional epoxy compound having anthracene skeletons,

[0104]Epikote 828EL, which is a bisphenol A-type epoxy resin (product of JER; epoxy equivalent: 187), or Epiclon HP-7200, which is a dicyclopentadiene-type epoxy resin (product of JER; epoxy equivalen...

example 6

[0117]In comparison with the aforementioned conductive paste of Example 1, C11-Z-CN (product of Shikoku Chemicals Corporation; 1-cyanoethyl-2-undecyl imidazole; melting point: about 50° C.; molecular weight: 275) was employed as a cure accelerator in place of 2E4MZ-CN, and, with this exception, otherwise the same compounding conditions were chosen to prepare a conductive paste having the composition listed in Table 2.

[0118]In similar way as in Examples 1 to 5, in Example 6, in the one-component epoxy thermosetting resin component therefor, the content ratio of the epoxy compound having naphthalene skeletons to other epoxy compounds was 3:1, and on the other hand, the blending ratio of 0.9 molecule of the above-described dicarboxylic-acid derived cyclic acid anhydride to 2 epoxy groups was selected. In addition, 0.016 mole of the imidazole compound, which is a cure accelerator, was added to 1 mole of the epoxy group. Further, a silane coupling agent was added at a ratio of 1.0 part b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting temperature | aaaaa | aaaaa |

| melting temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com