Light emitting element

a technology of light-emitting elements and light-emitting devices, which is applied in the direction of discharge tubes/lamp details, discharge tubes/lamp details, luminescent compositions, etc., can solve the problems of low light-emitting efficiency and lower efficiency of light-emitting devices, and achieve high-efficiency light-emitting, facilitate light-emitting, and increase light-emitting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(First Embodiment)

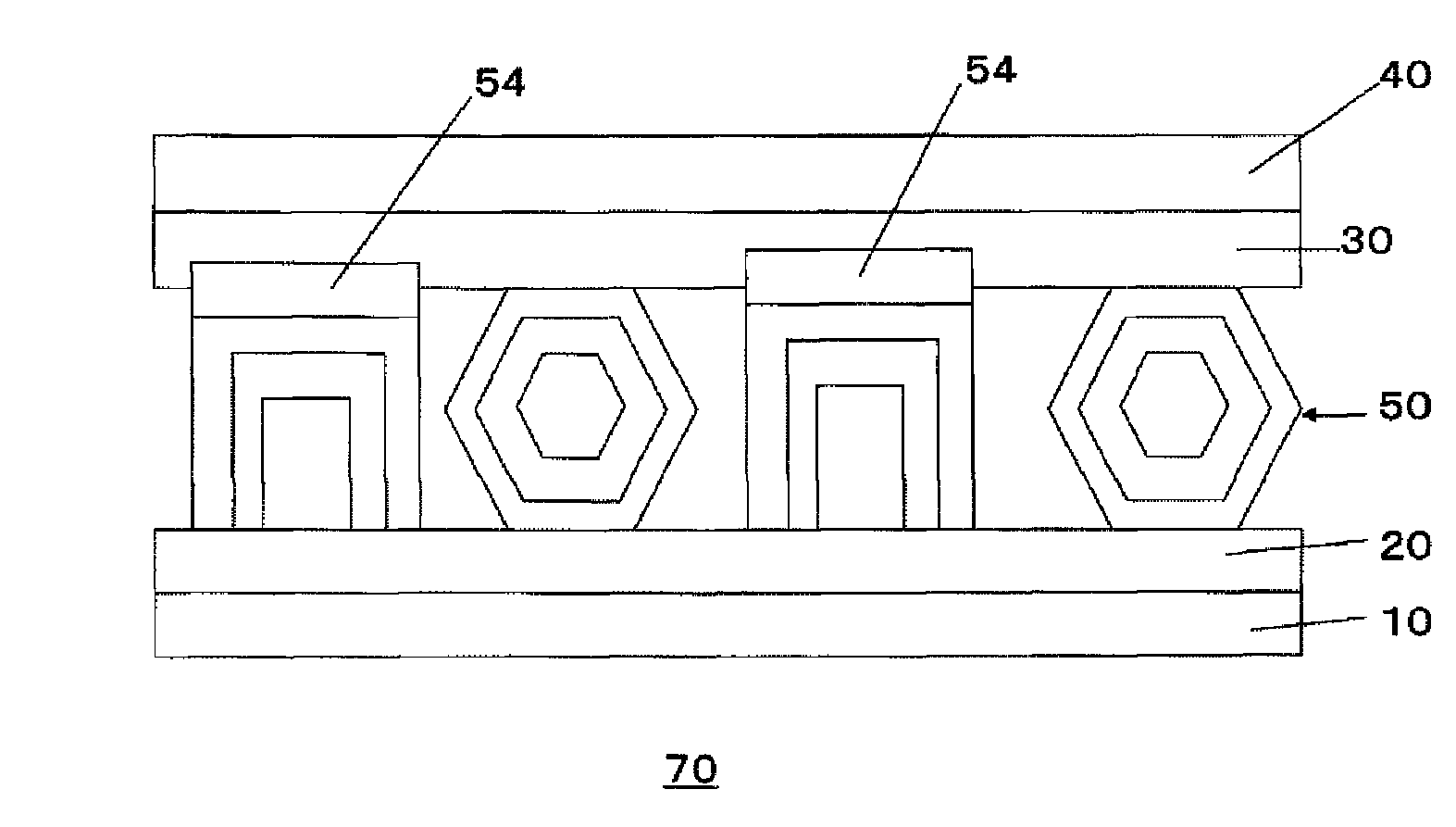

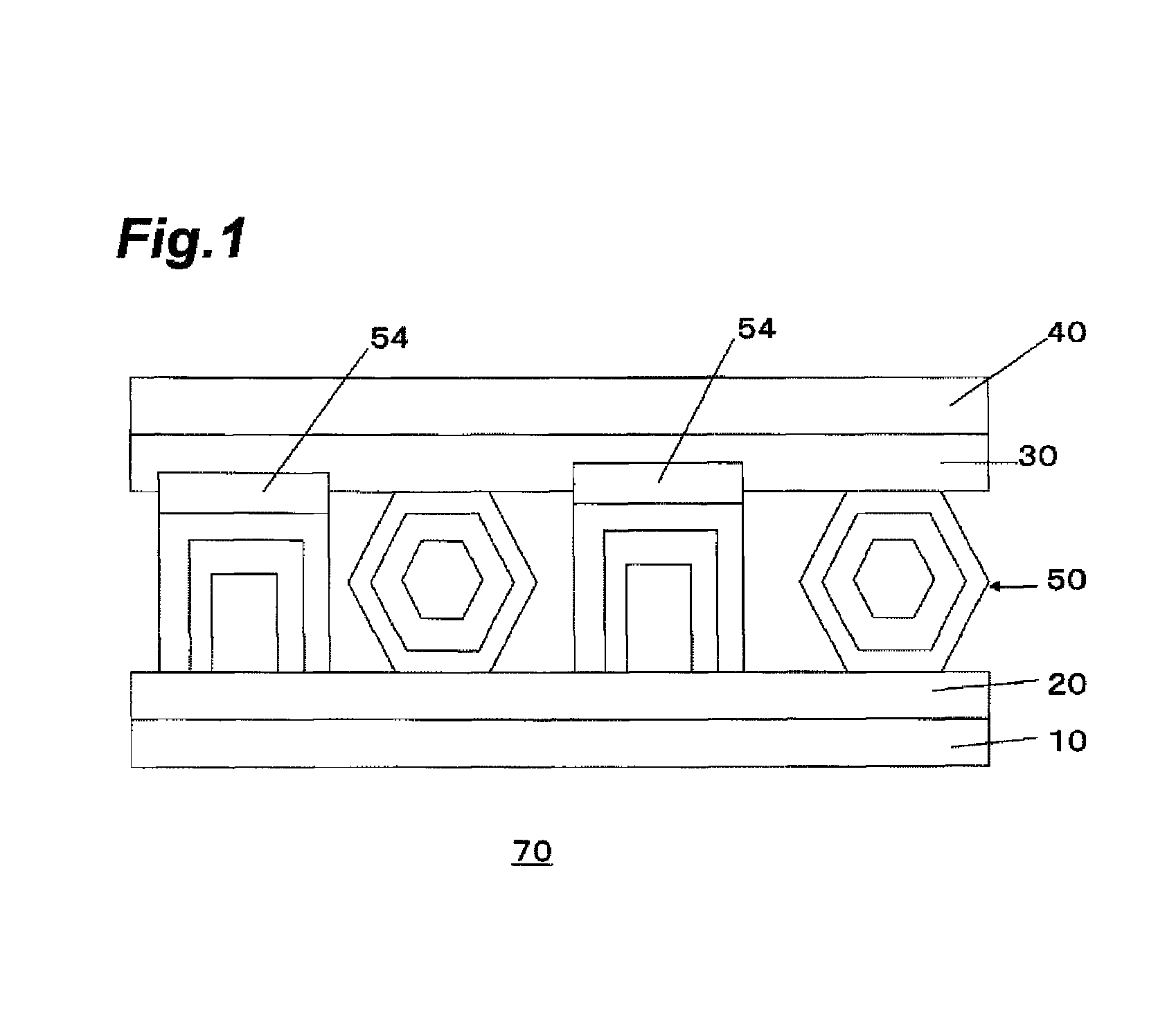

[0052]FIG. 1 is a cross-sectional view schematically illustrating the structure of a light emitting device 70 according to the present first embodiment. In the light emitting device 70, on a lower substrate 10, there are placed a lower electrode 20, phosphor particles 50, an upper electrode 30, and an upper substrate 40, in the mentioned order. In the light emitting device 70, the plurality of phosphor particles 50 placed between the lower electrode 20 and the upper electrode 30 form a phosphor layer. Further, FIG. 1 illustrates a minimum structure necessary for light emission, and other members may be provided in addition thereto.

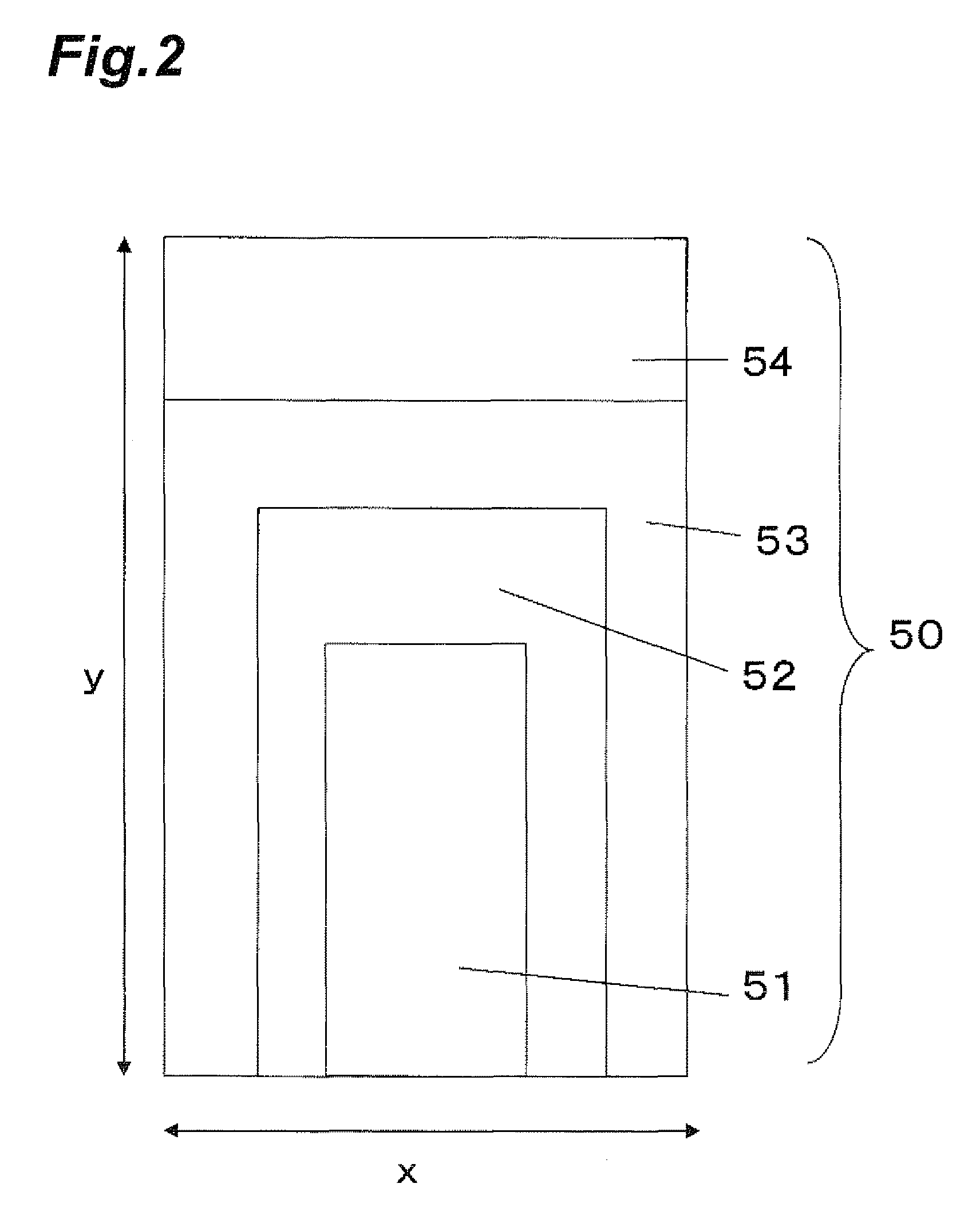

[0053]FIG. 2 is a cross-sectional view illustrating the cross-sectional structure of a phosphor particle 50 taken along the direction of the c axis thereof. FIG. 3 is a cross-sectional view illustrating the cross-sectional structure of the phosphor particle 50 taken along a plane perpendicular to the c axis thereof. In the light emitting ...

first example

[0077]Hereinafter, there will be described a method for fabricating a light emitting device according to the first example. In this case, at first, phosphor particles were formed, and the resultant phosphor particles were sandwiched between electrodes to form a light emitting device.

[0078](a) A sapphire substrate having a surface orientation of (0,0,0,1) and having a diameter of 5.08 cm (2 inches) was employed as a growth substrate 61. An SiO2 film with a thickness of 5 micrometers was formed as a growth mask 62 on the sapphire substrate 61 through a formation mask, through sputtering. It was formed through sputtering, using a SiO2 target as a target, in an atmosphere of an Ar gas. The growth mask 62 had hole portions with a diameter of 3 micrometers.

[0079](b) An AlN film was formed as nucleuses 51 thereon through sputtering. It was formed through sputtering, using an Al target as a target, in an atmosphere of an N2 gas. The AlN was grown in the direction of the c axis to have a thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com