Electrolytic cell for generating sterilization solutions having increased ozone content

a technology of ozone content and electrolysis cell, which is applied in the direction of oxygen/ozone/oxide/hydroxide, non-contaminated water treatment, water/sewage treatment by oxidation, etc., can solve the problems of inability to maintain the system, lack of highly trained personnel and equipment, and inability to achieve optimal system maintenance, etc., to achieve the effect of increasing the ratio of ozone to chorine based compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

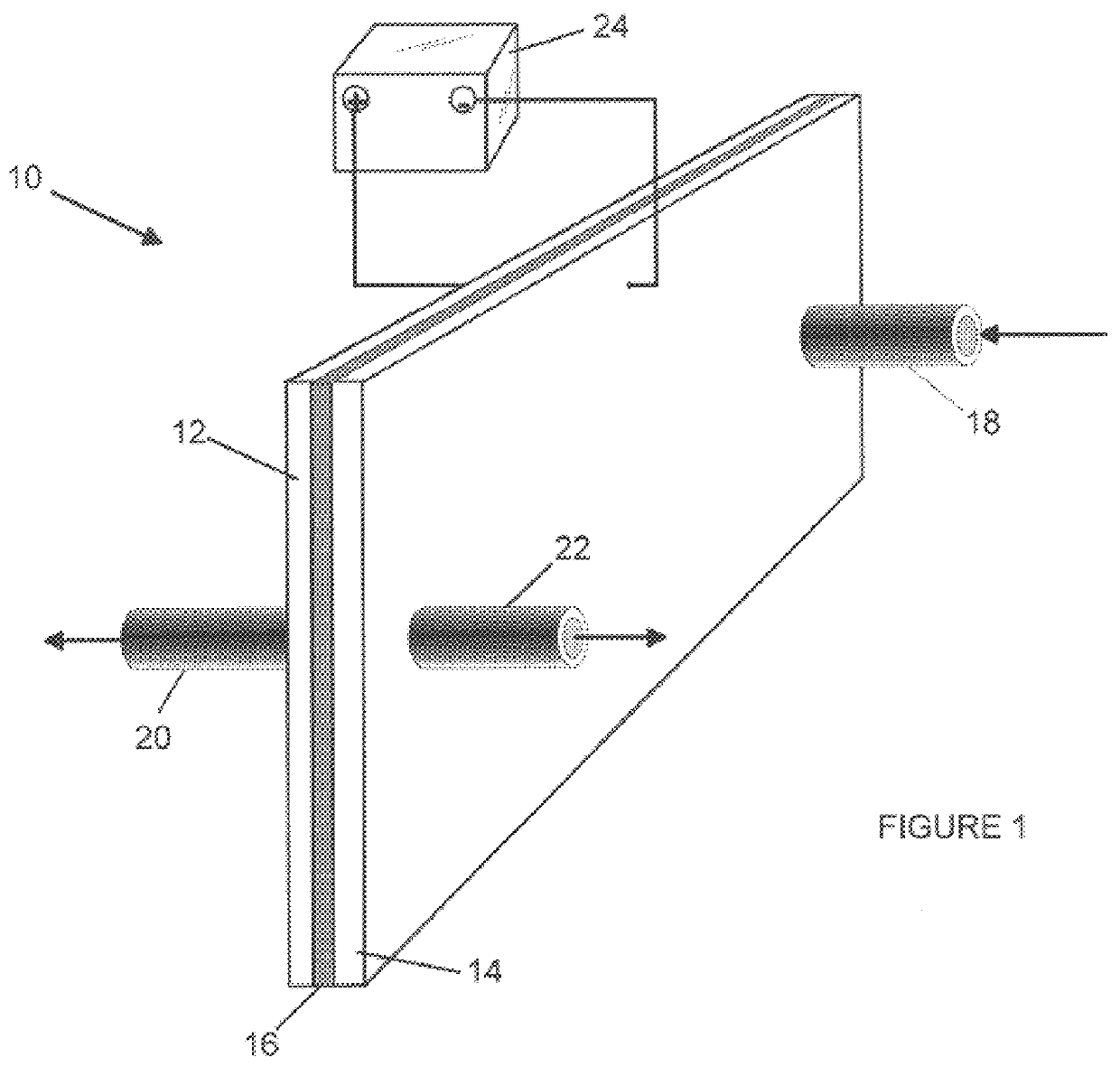

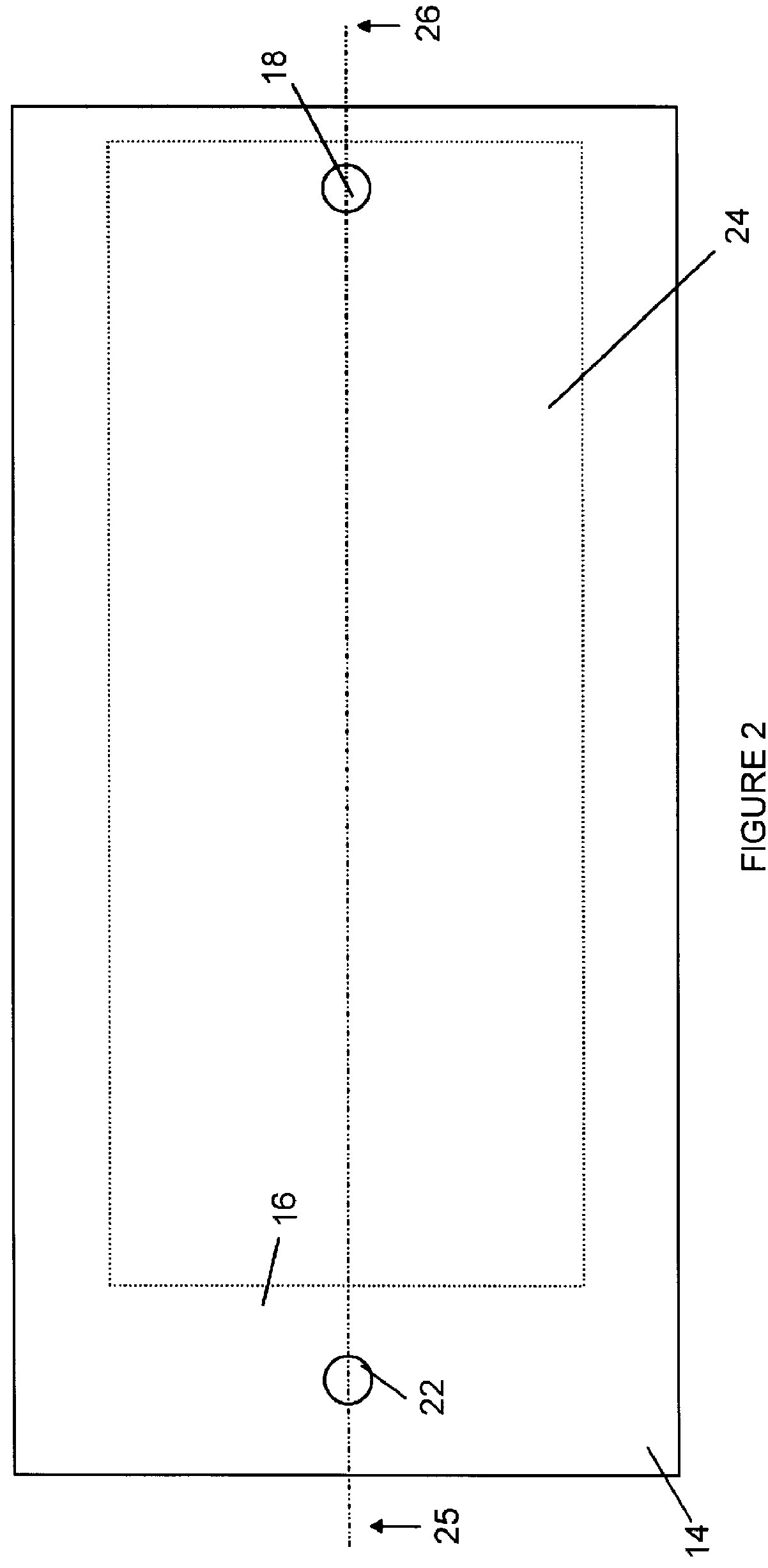

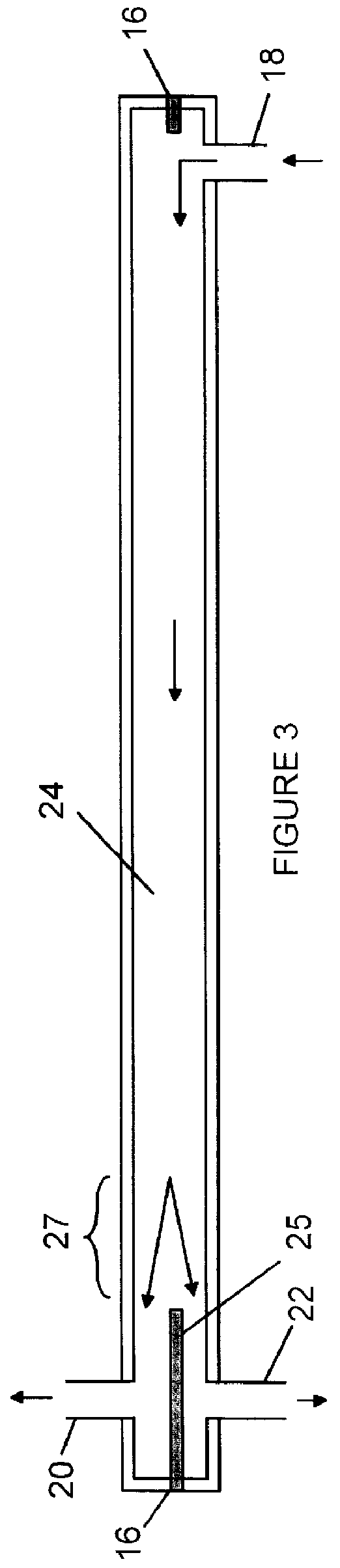

The manner in which an electrolytic cell 10 according to the present invention operates can be more easily understood with references to FIGS. 1-3. Electrolytic cell 10 includes an anode 12 and a cathode 14 which are separated by an insulating gasket 16 thereby forming a flow chamber 24 through which a salt solution is passed. The salt solution is introduced through an input port 18 and exits through an anode port 20 and a cathode port 22. A DC voltage is maintained between anode 12 and cathode 14 with the aid of a power source 24. Anode 12 and cathode 14 are preferably constructed from titanium. In addition, anode 12 preferably includes a Group VIII metal for the reasons discussed below.

Referring to FIG. 3, the flow of salt solution is divided by an extension of gasket 25 into anode and cathode output streams which exit through anode port 20 and cathode port 22, respectively. The flow in chamber 24 is laminar in nature. As the salt solution traverse the chamber 24, the pH of the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical potential | aaaaa | aaaaa |

| electrochemical | aaaaa | aaaaa |

| of time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com