Scanning exposure apparatus

a technology of exposure apparatus and scanning lens, which is applied in the direction of photomechanical apparatus, instruments, printing, etc., can solve the problems of difficult design and manufacture to realize both the high resolution and wide field of projection optical system, and difficulty in reducing exposure amount, so as to reduce the unevenness of exposure amount in the non-scanning direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

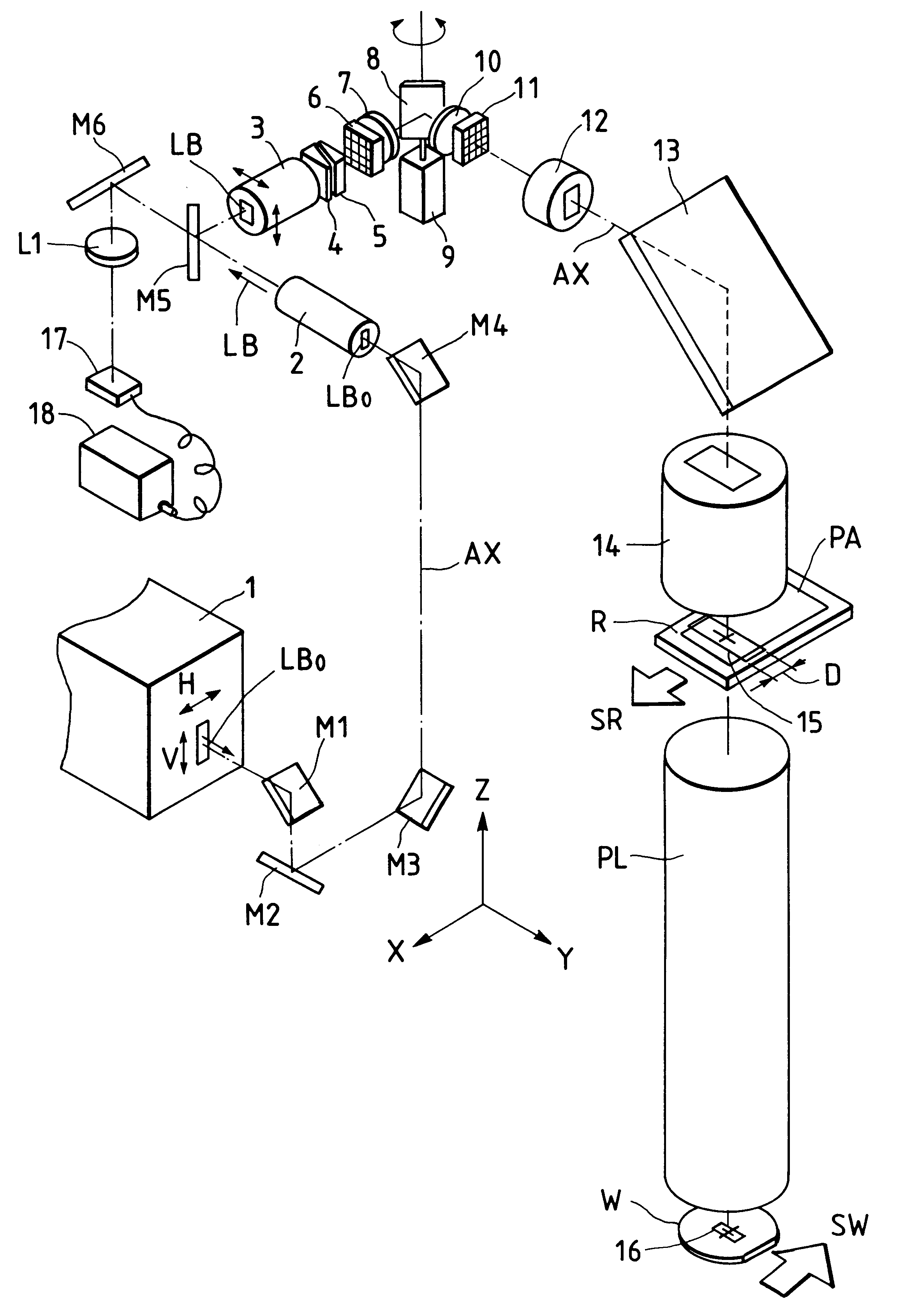

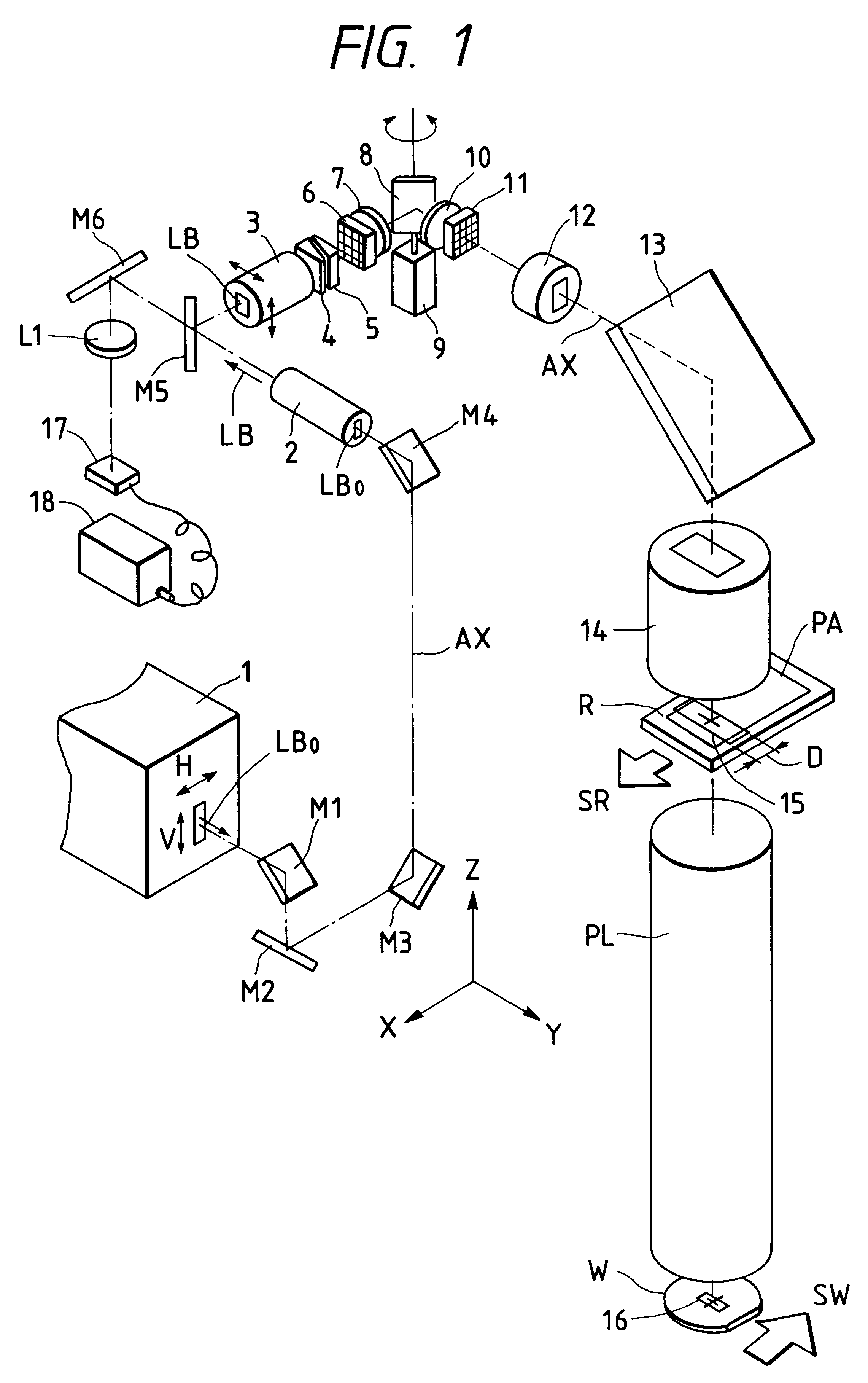

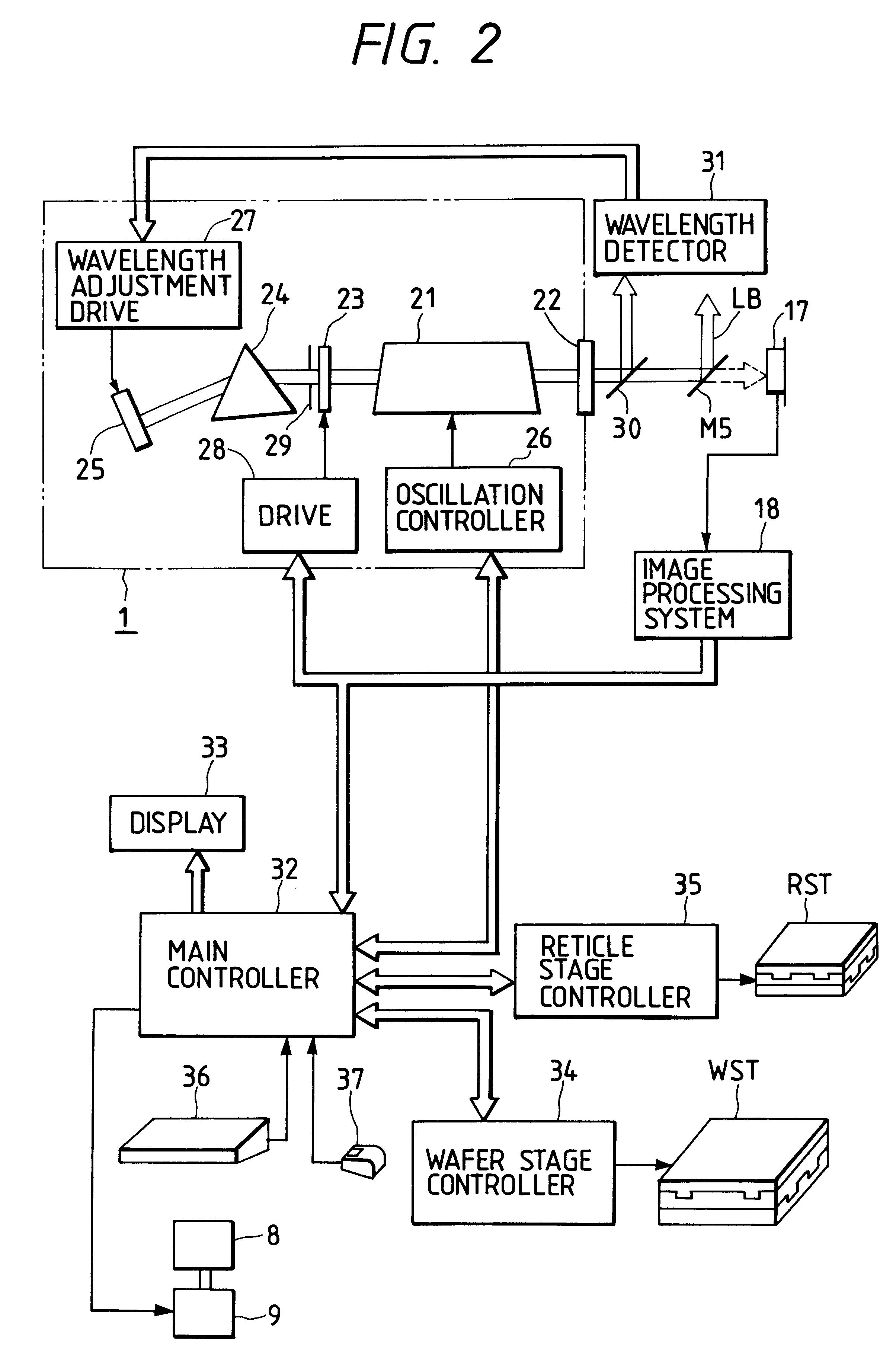

the present invention will be described below with reference to FIG. 1 to FIGS. 6A and 6B. In this embodiment, the present invention is applied to a step-and-scan type scanning exposure apparatus which comprises a pulse oscillation type laser light source.

Referring to FIG. 1, a laser beam LB.sub.0 in a far ultraviolet range (e.g., a wavelength of 248 nm) emitted from an excimer laser light source 1 is incident on a beam shaping optical system 2, including cylindrical lenses, via mirrors M1, M2, M3, and M4. The sectional shape of the laser beam LB.sub.0 emitted from the excimer laser light source 1 is an elongated rectangular shape in which the dimension in the horizontal direction (H direction) is considerably smaller than that in the vertical direction (V direction). The beam shaping optical system 2 expands the dimension in the horizontal direction of the laser beam LB.sub.0, and outputs a laser beam LB with a sectional shape having substantially the same aspect ratio (almost simi...

second embodiment

the present invention will be described below with reference to FIG. 7. FIG. 7 shows the arrangement of a scanning projection exposure apparatus according to the embodiment comprising a pulse oscillation type laser light source. The same reference numerals in FIG. 7 denote parts having the same functions and effects as those in FIG. 1.

Referring to FIG. 7, a laser beam LB.sub.0 in a far (or deep) ultraviolet range (e.g., a wavelength of 248 nm) emitted from an excimer laser light source 1 is incident on a beam shaping optical system 2 including cylindrical lenses. In general, the sectional shape of the laser beam LB.sub.0 emitted from the excimer laser light source 1 is an elongated rectangular shape in which the dimension in the horizontal direction (H direction) is considerably smaller than that in the vertical direction (V direction). The beam shaping optical system 2 shapes the laser beam LB.sub.0 into a beam which has a square section with an aspect ratio of 1 : 1, and outputs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com