Cold cathode ion beam deposition apparatus with segregated gas flow

a technology of ion beam deposition and gas flow, which is applied in the direction of ion beam tubes, instruments, vacuum evaporation coating, etc., can solve the problems of undesirable gas flow, adverse effect on the operability and/or efficiency of the ion beam source, and adverse effect on the electric field potential between, so as to reduce the likelihood of undesired insulative material buildup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

In the following description, for purposes of explanation and not limitation, specific details are set forth in order to provide an understanding of certain embodiments of the present invention. However, it will apparent to those skilled in the art that the present invention may be practiced in other embodiments that depart from these specific details. In other instances, detailed descriptions of well known devices, gases, fasteners, and other components / systems are omitted so as to not obscure the description of the present invention with unnecessary detail. Referring now more particularly to the accompanying drawings, in which like reference numerals indicate like parts / elements / components / areas throughout the several views.

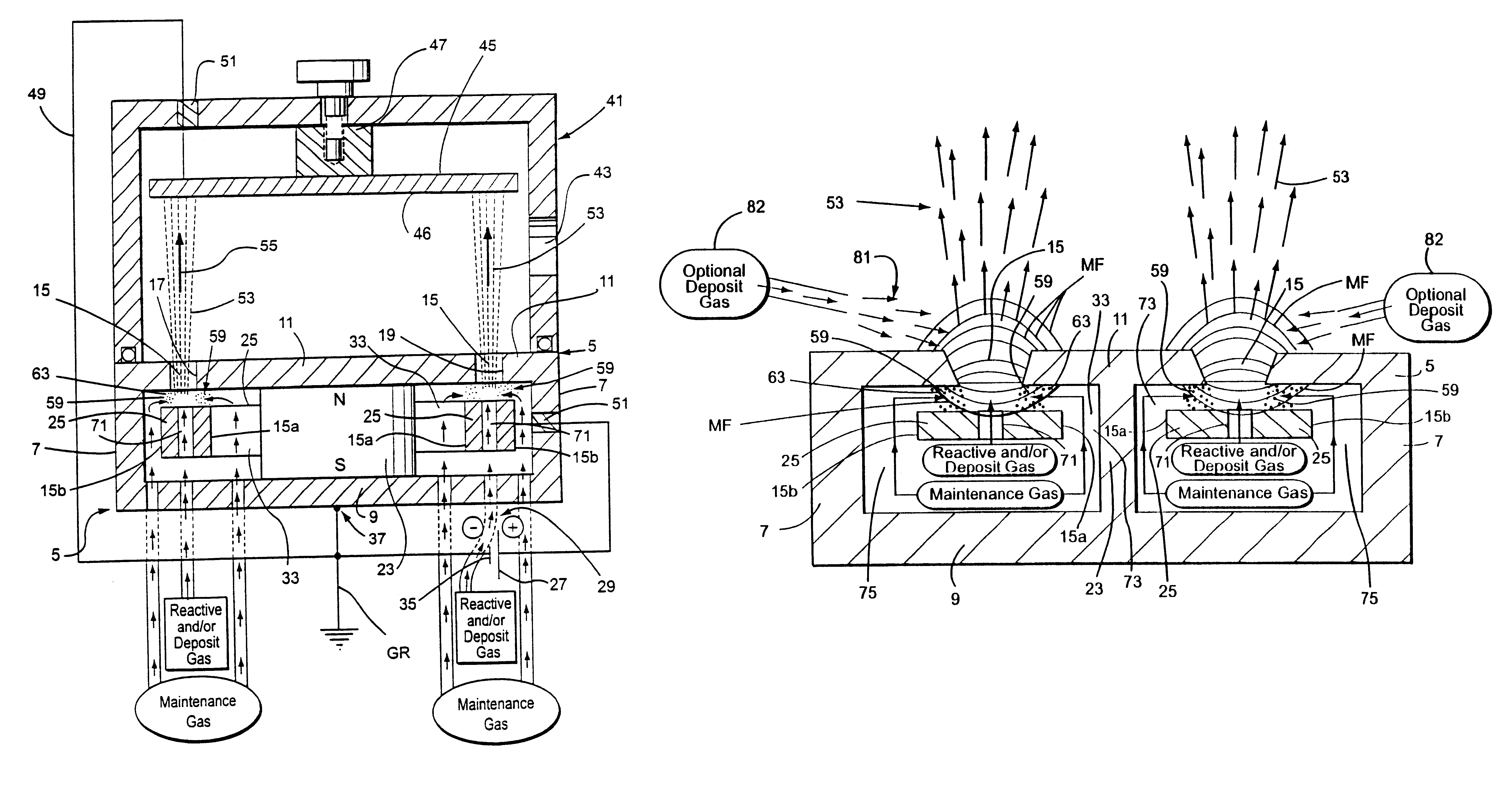

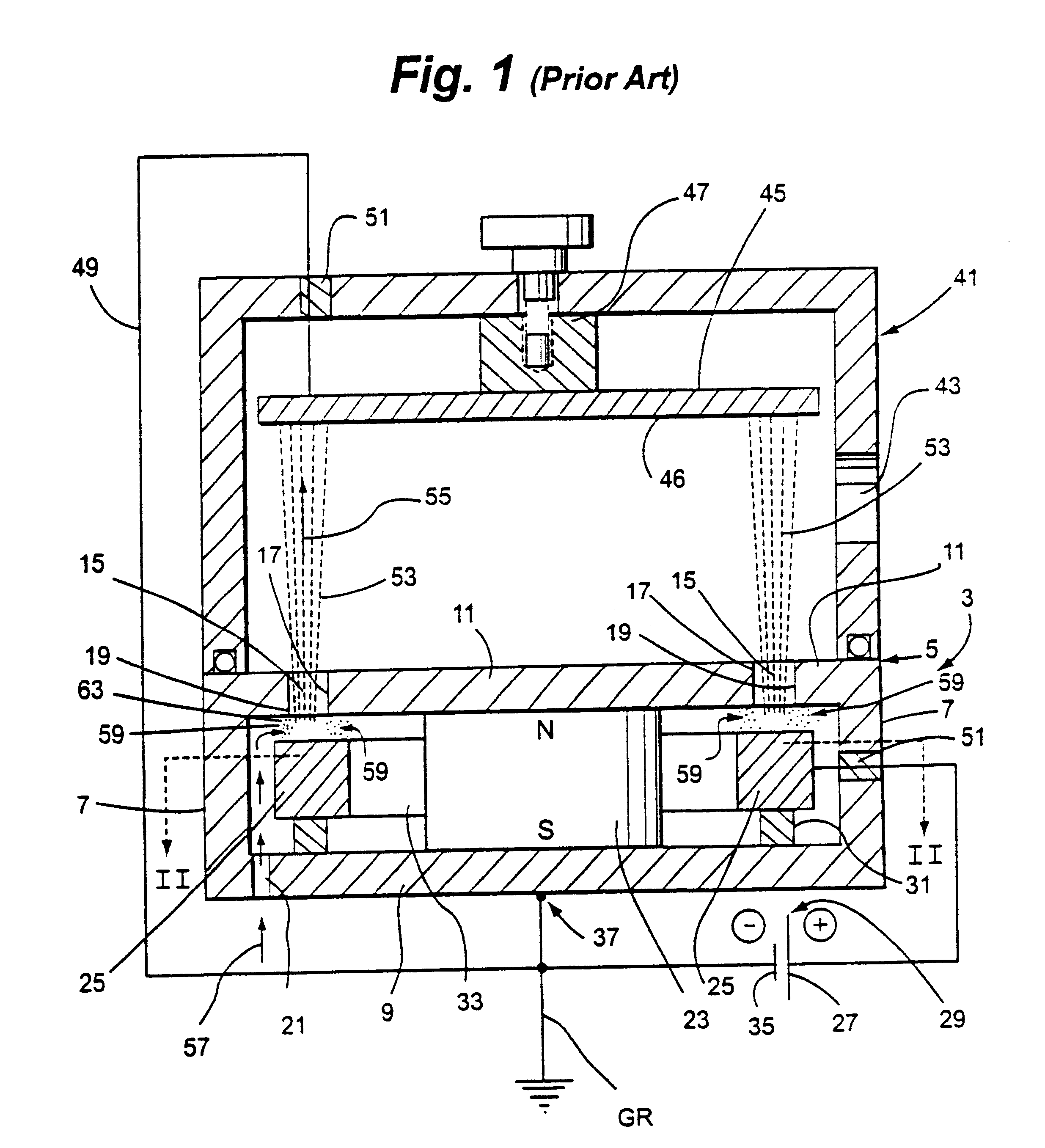

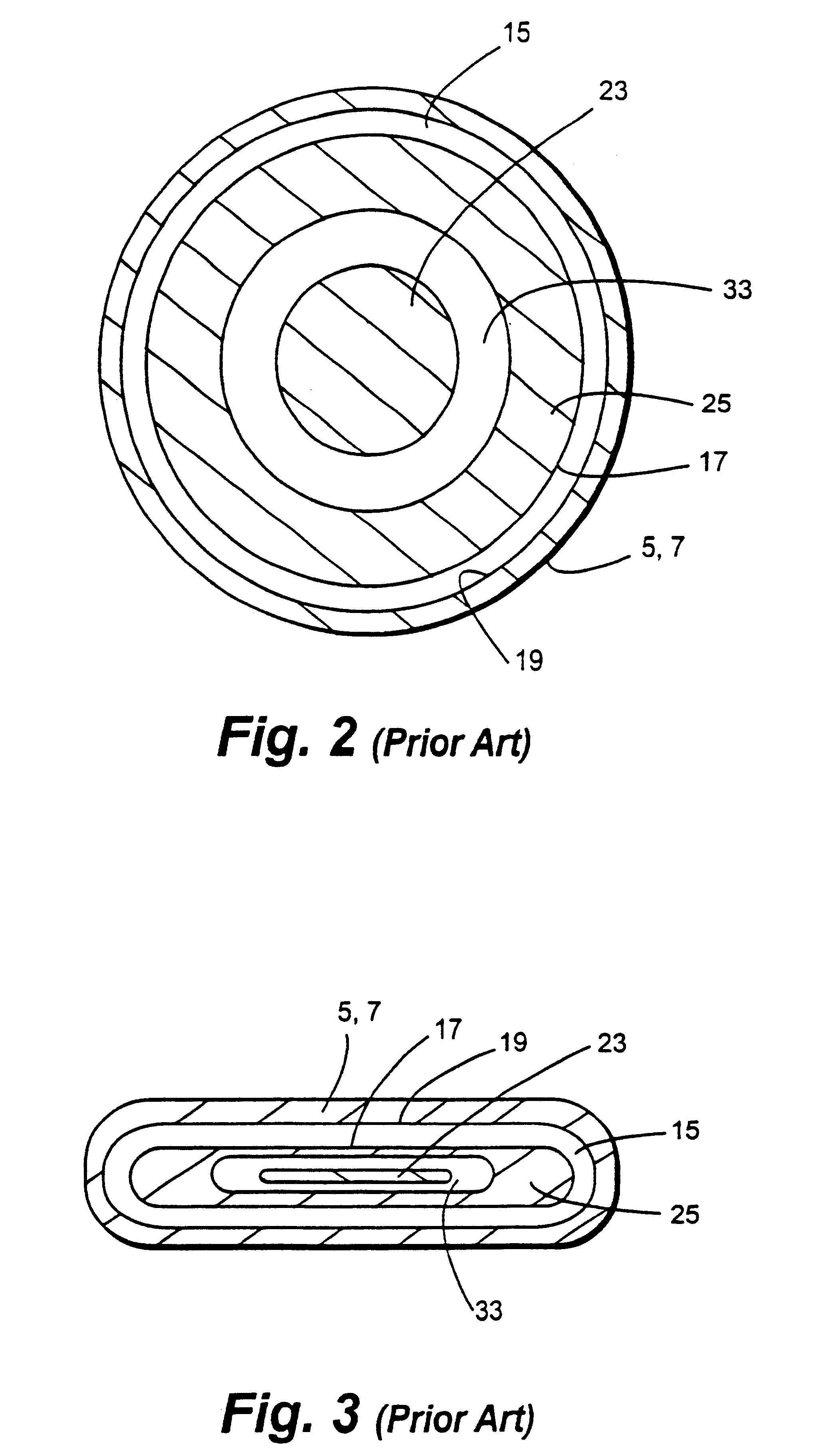

FIG. 4 is a schematic and partial sectional view of an ion source according to an exemplary embodiment of this invention. The cold cathode closed drift type ion source of FIG. 4 is similar in many respects to that of FIGS. 1-3. Closed loop ion emitting slit 15 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical gap | aaaaa | aaaaa |

| magnetic field | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com