Narrow band excimer laser and wavelength detecting apparatus

a wavelength detection and narrow band technology, applied in the direction of optical radiation measurement, instruments, active medium materials, etc., can solve the problems of high degree of coherence of output light beam, spectrum purity degradation, and difficulty in achieving 100% locking efficiency, so as to reduce loss, increase the number of prisms, the effect of large transmissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

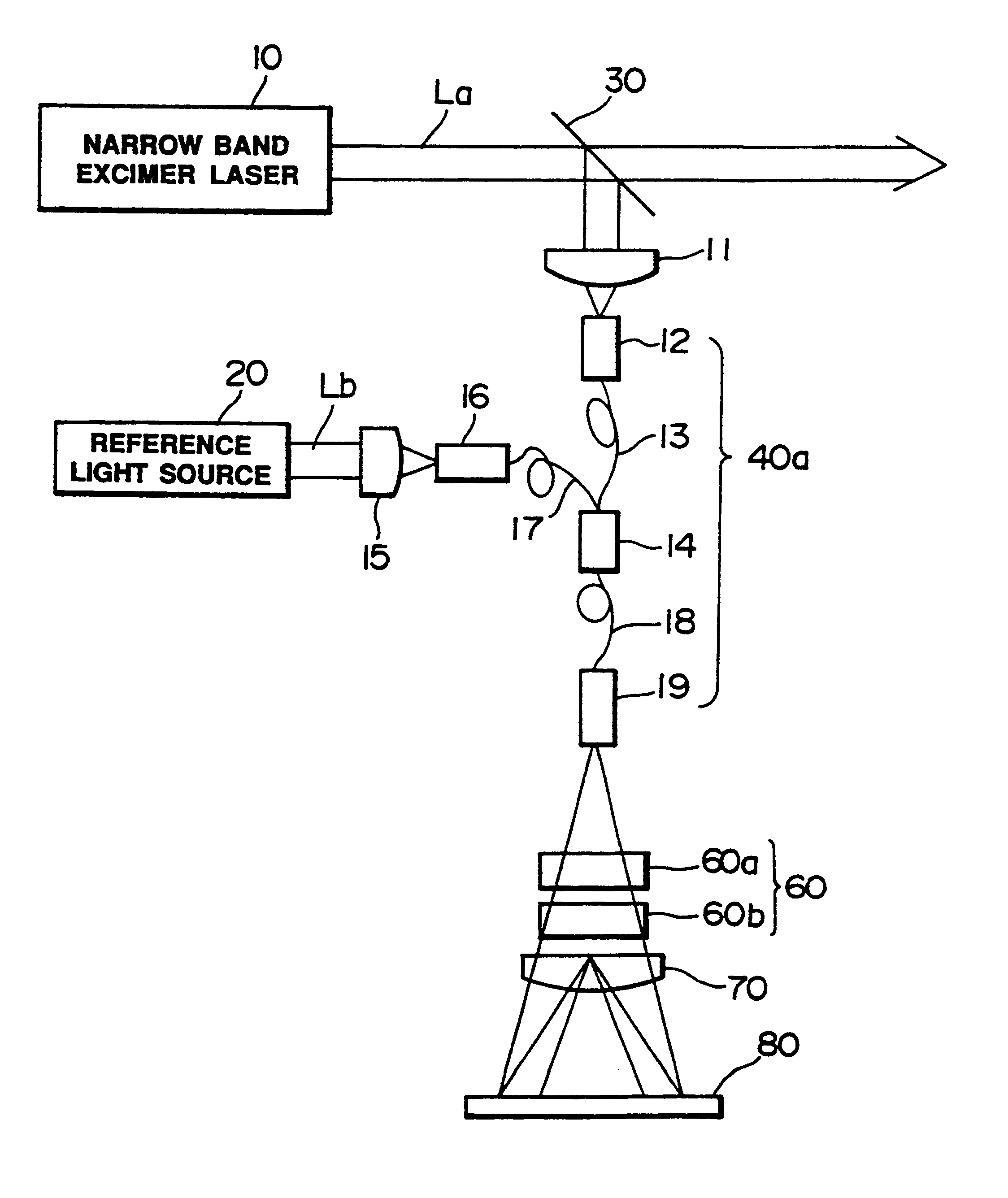

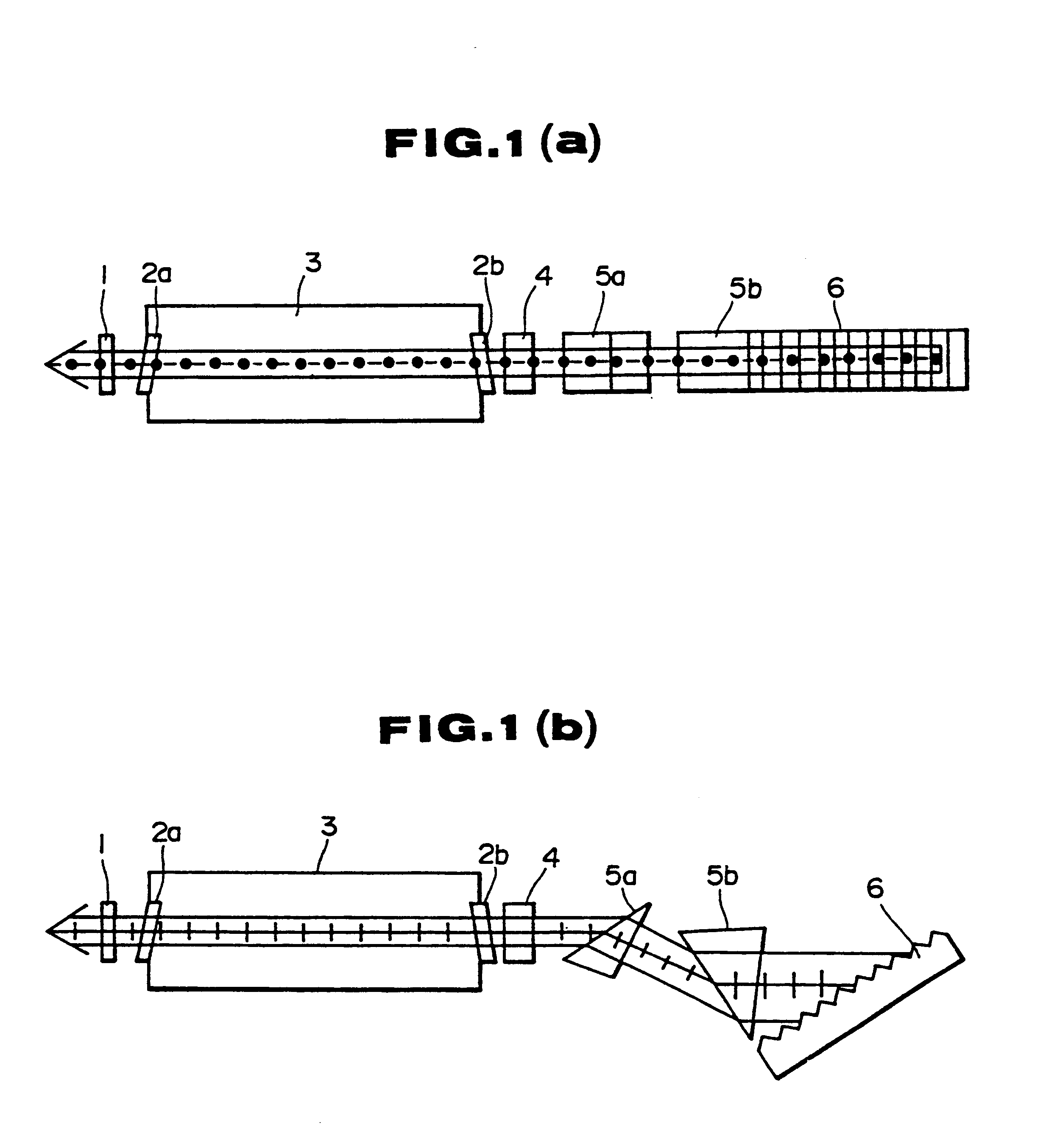

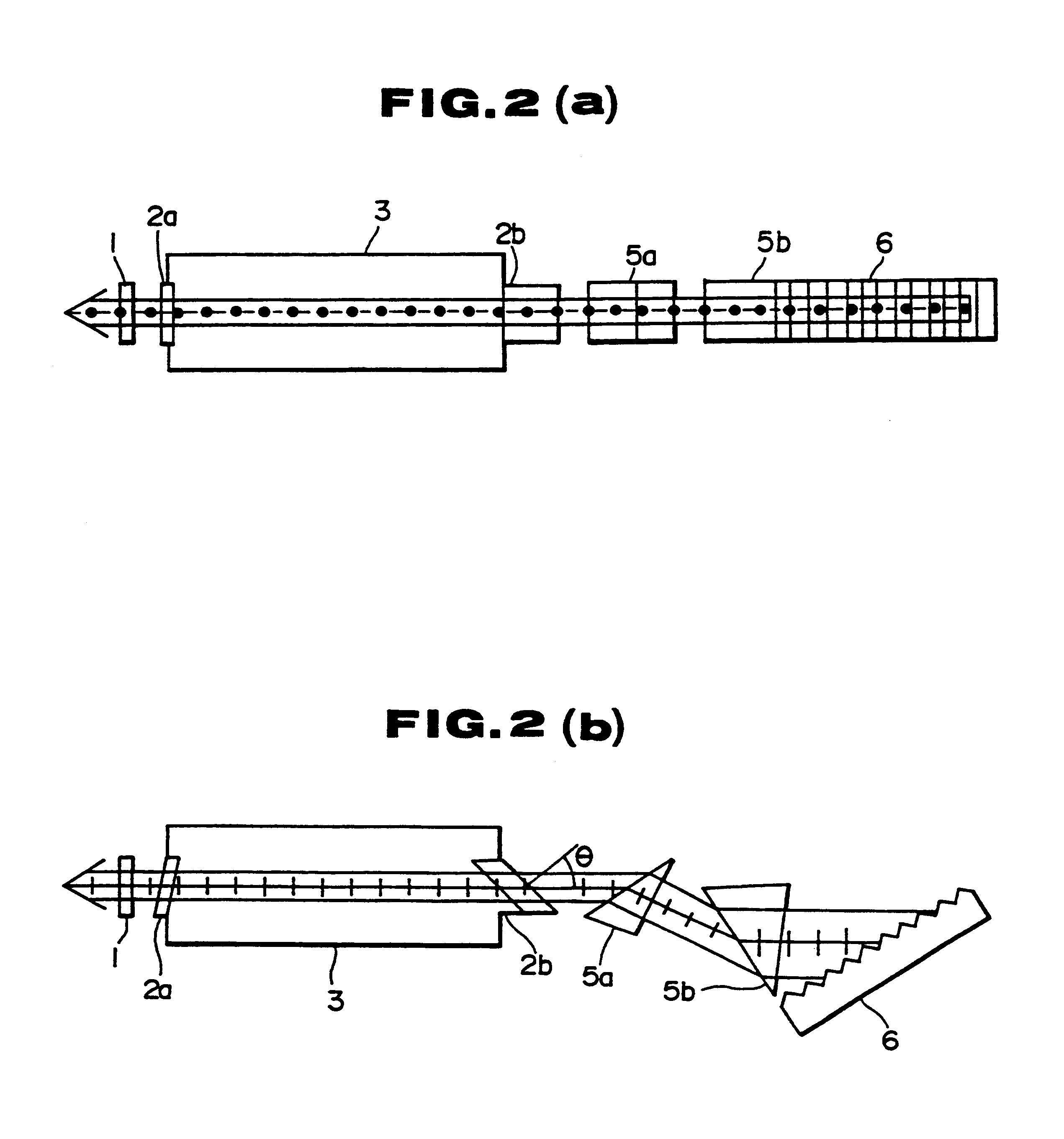

The embodiments-of this invention will now be described with reference to the accompanying drawings. The narrow band excimer laser shown in FIGS. 1(a) and 1(b) comprises a front mirror 1, and a grating 6 acting as a rear mirror and a wavelength selective element. Between the front mirror 1 and the grating 6, a laser chamber 3, a polarizing element 4, and two prisms 5a and 5b acting as a beam expander (prism beam expander) are provided. Thus, a laser chamber or cavity is constructed between the front mirror 1 and the grating 6.

The laser chamber 3 is filled with a laser gap containing KrF, etc. which can circulate in the chamber 3. For the purpose of exciting the laser gas, discharge electrodes (not shown) are provided in the laser chamber 3. Windows 2a and 2b are provided at both ends of the laser chamber 3 at predetermined angles.

The purpose of the grating 6 is to select a beam having a specific wavelength by utilizing diffraction of light beam. The grating 6 is provided with a numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com