Precooled cryogenic ablation system

a cryogenic ablation and pre-cooled technology, applied in the field of biological tissues cooling, can solve the problems of greater tissue destruction, and achieve the effect of maximizing the cooling power and achieving the lowest possible temperatur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

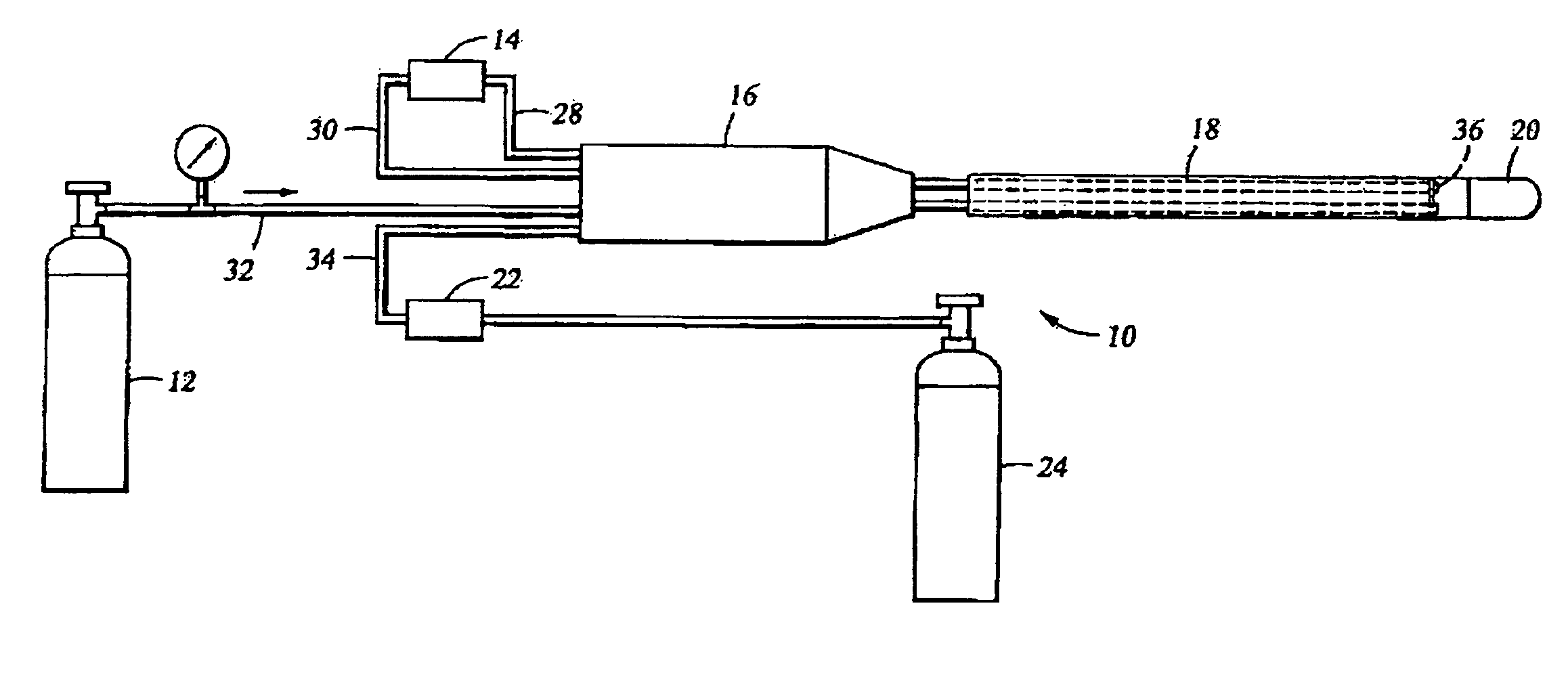

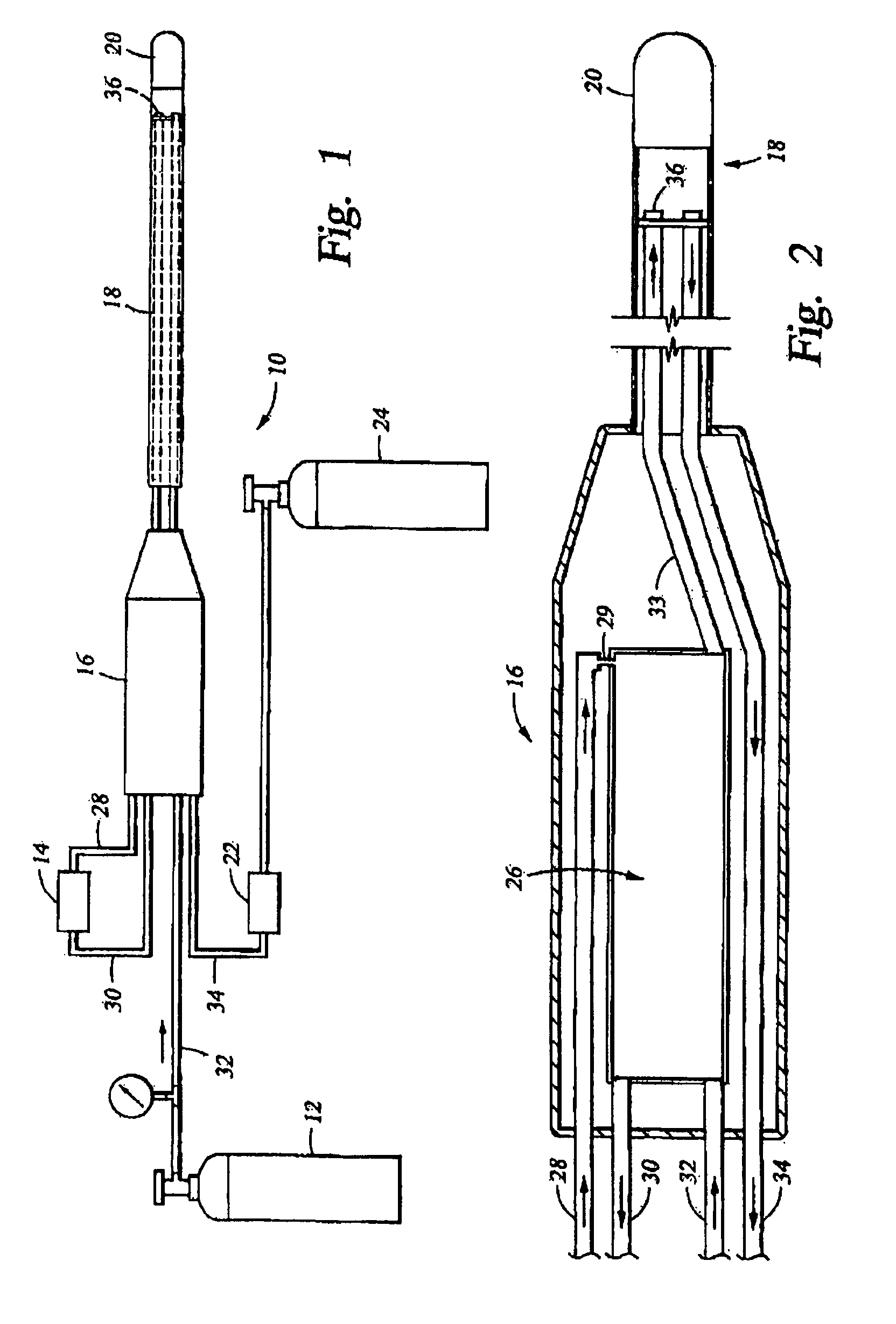

[0020]The present invention lies in the appropriate use of a secondary evaporative refrigeration system to precool and liquefy the primary high pressure refrigerant, before passage of the primary refrigerant through a primary Joule-Thomson expansion element. This is intended to enable the generation of a sufficiently low temperature, and to maximize the available cooling power, at the cold tip of a cryosurgical probe or catheter.

[0021]Pre-cooling the primary refrigerant to an at least partially liquid state, prior to feeding it to the primary expansion element, is the focus of the present invention. This pre-cooling can be done prior to introducing the primary refrigerant into the catheter, by the use of a heat exchanger in a cooling console. Alternatively, pre-cooling can be provided nearer to the treatment area, such as in the handle of a cryoprobe, or at the proximal end of a catheter.

[0022]An important parameter in the design of a cryosurgical device is the cooling power which t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com