Spraying and drying process and apparatus for Chinese medicine concentrate

A drying process and drying equipment technology, which is applied in the direction of pharmaceutical formulations, devices for making medicines into special physical or ingestible forms, plant raw materials, etc., can solve problems such as unstable spraying, uneven drying, and low drying intensity, and achieve The effect of optimizing the drying preparation steps, compact and reasonable equipment structure, and improving the yield of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

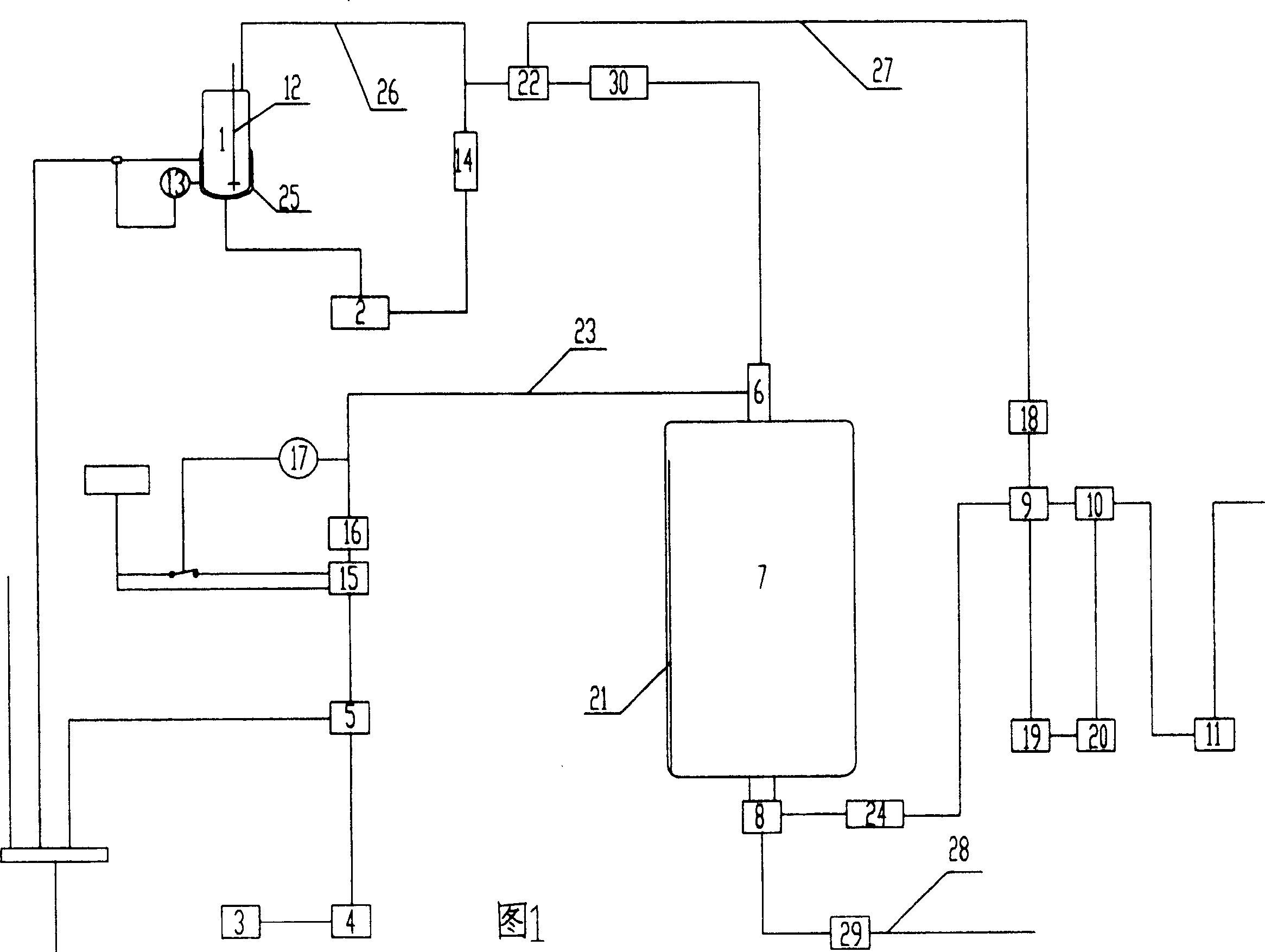

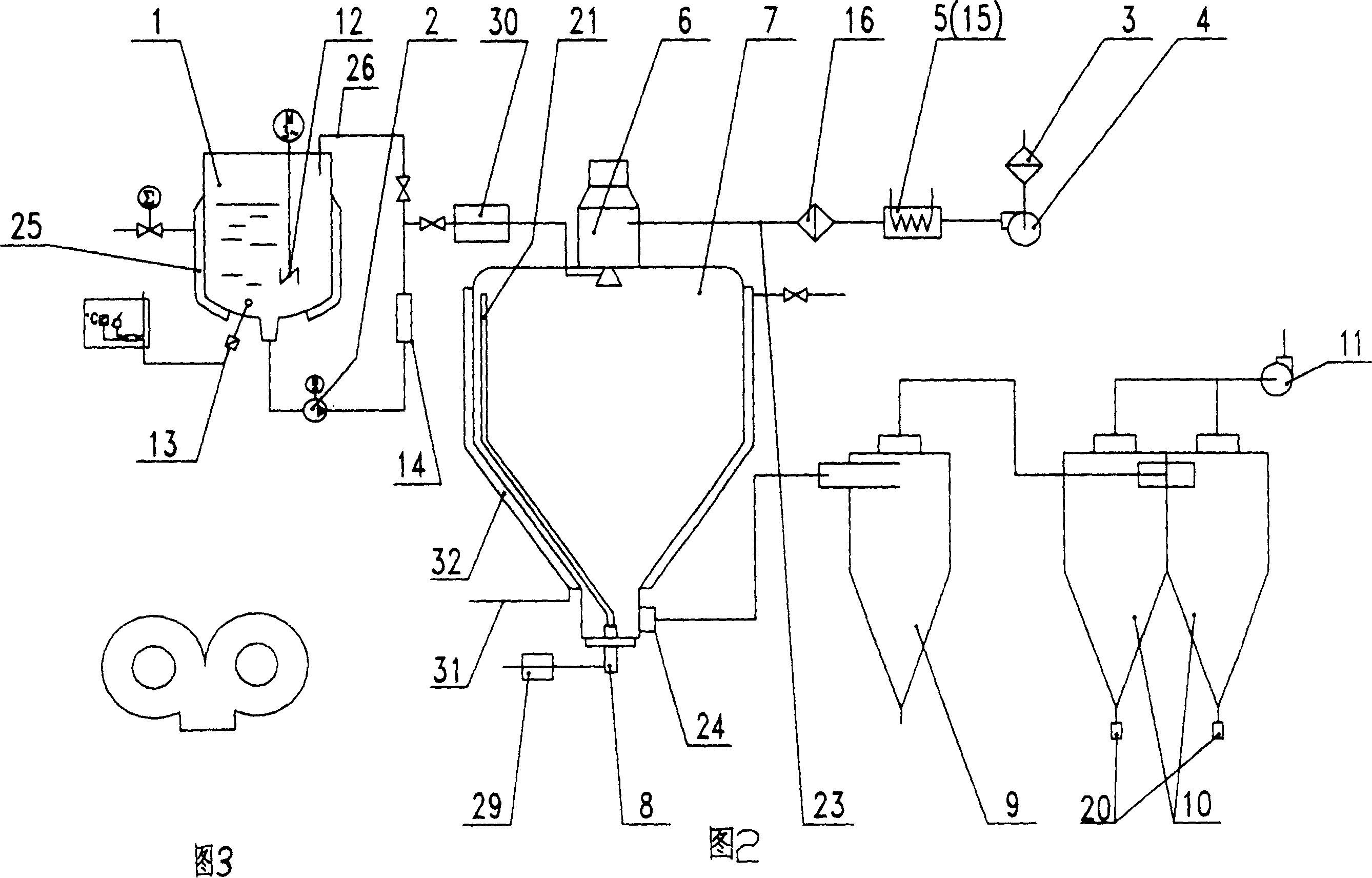

[0013] As shown in Fig. 1 and Fig. 2, the equipment of the present invention includes a spray drying tower 7, a rotatable attachment sweeping device 8 with a compressed air blowing pipe 21 is set in the spray drying tower 7, and the attachment sweeping device 8 It is connected to a compressed air line 28 on which a filter drying device 29 is arranged. Centrifugal atomizer 6 is set on the top of spray drying tower 7, and atomizer 6 is connected with the hot-blast pipeline 23 that imports filtered hot air, and two-stage air filter and two-stage air heater are set at the other end of hot-blast pipeline 23, i.e. Starting from the air inlet, a coarse-effect air filter 3, an air heater 5 adopting a steam heating method, an air heater 15 adopting an electric heating method and a precision air filter 16 are arranged in sequence. The equipment of the present invention also includes a circulating circuit 26 composed of a liquid supply tank 1, a quantitative liquid supply pump 2 and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com