Method for producing nano-wire or nano-belt of zinc oxide

A zinc oxide nanowire, zinc oxide nanotechnology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of high reaction temperature, unavailability, strict requirements on atmospheric conditions, etc., and achieves low sintering temperature, simple operation and controllable strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

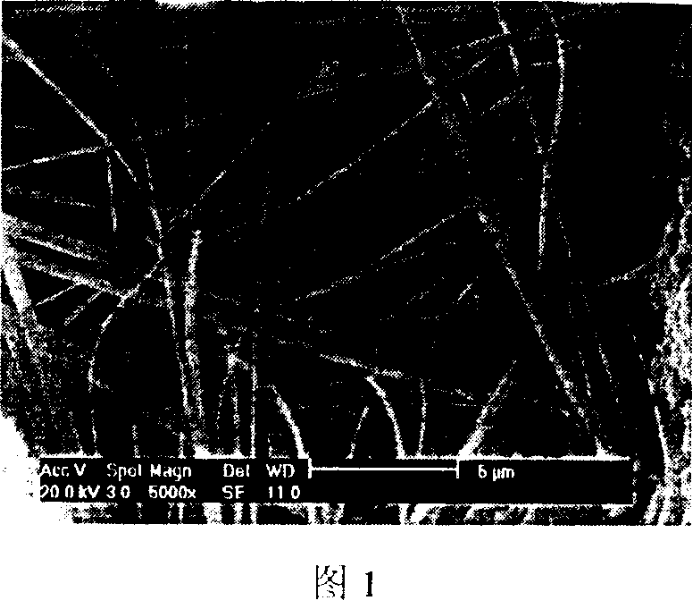

[0017] In a quartz beaker, dissolve 2g of polyvinyl alcohol with a degree of polymerization of 1000-1500 in 50ml of deionized water at 90°C; add 1g of zinc acetate, stir it mechanically for 0.5h at a speed of 800 rpm, and disperse it with a 40KHz, 150W ultrasonic wave 0.5h. Lay the etched quartz substrate on the bottom of the quartz beaker. Then place the quartz cup in an oven and raise the temperature to 120°C at a rate of 5°C / min and keep it warm for 0.5h until drying; raise the temperature to 200°C at a rate of 3°C / min and keep it warm for 1h. The sample was transferred to a muffle furnace and calcined at 300°C for 0.5h; the temperature was raised to 400°C at a rate of 5°C / min and held for 0.5h; the temperature was raised to 550°C at a rate of 8°C / min and held for 1h. SEM observation found that nanowires with a diameter of 30-50 nm and a length of more than 15 μm and nanobelts with a width of 100-500 nm and a length of more than 20 μm were formed on the substrate, as shown...

Embodiment 2

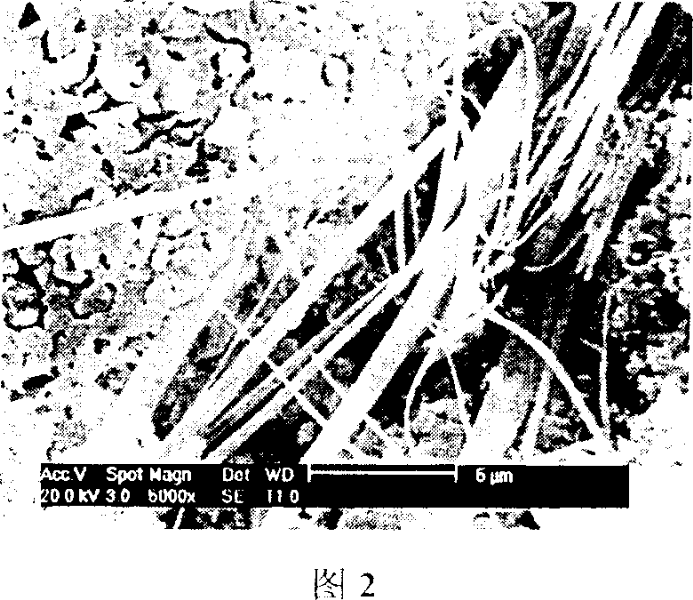

[0019] This example is similar to Example 1, except that the consumption of zinc acetate and polyvinyl alcohol in step 1 is 2g respectively, and the temperature is raised to 130°C at a rate of 9°C / min, and kept for 0.5h until drying; The temperature was raised to 210°C at a rate of °C / min and kept for 1h. The sample was transferred to a muffle furnace and calcined at 310°C for 0.5h; the temperature was raised to 400°C at a rate of 7°C / min and kept for 1h; the temperature was raised to 560°C at a rate of 10°C / min and kept for 1h. SEM observation found that the product consists of nanobelts with a width of about 100-200 nm and a length of about 15 μm and an area of about 2-6 μm. 2 It is composed of zinc oxide scale flakes, and there are also several nanowires with a diameter of about 20-60nm, as shown in Figure 2.

Embodiment 3

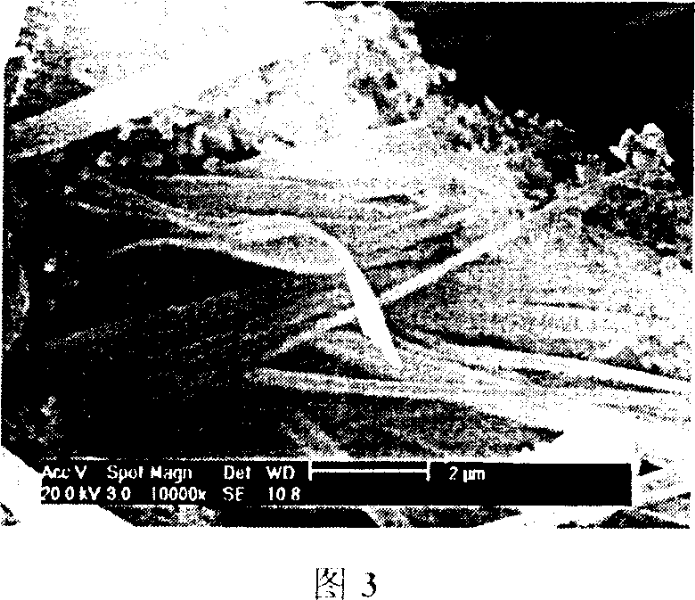

[0021] This example is similar to Example 1, and this example is similar to Example 1, except that the dosages of zinc acetate and polyvinyl alcohol in step 1 are 2g and 1g respectively, and the temperature is raised to 150°C at a rate of 9°C / min , keep warm for 1h until drying; raise the temperature to 210°C at a rate of 3°C / min, and keep warm for 1.5h. The sample was transferred to a muffle furnace and calcined at 310°C for 1 hour; the temperature was raised to 420°C at a rate of 10°C / min, and kept for 1 hour; the temperature was raised to 560°C at a rate of 10°C / min, and held for 3 hours. SEM observation found that the product was composed of nanobelts with a width of 100-1000 nm and a length of about 6 μm, as shown in FIG. 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com