Method for preparing surface microporous titanium of titanium-based biological medical material

A biomedical and surface microporous technology, applied in chemical instruments and methods, medical science, titanium compounds, etc., can solve the problems of difficult control of surface microporous titanium pore size, reduced fatigue resistance, high preparation cost, etc., to solve the problem of planting Effects of failure, increased surface area, low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

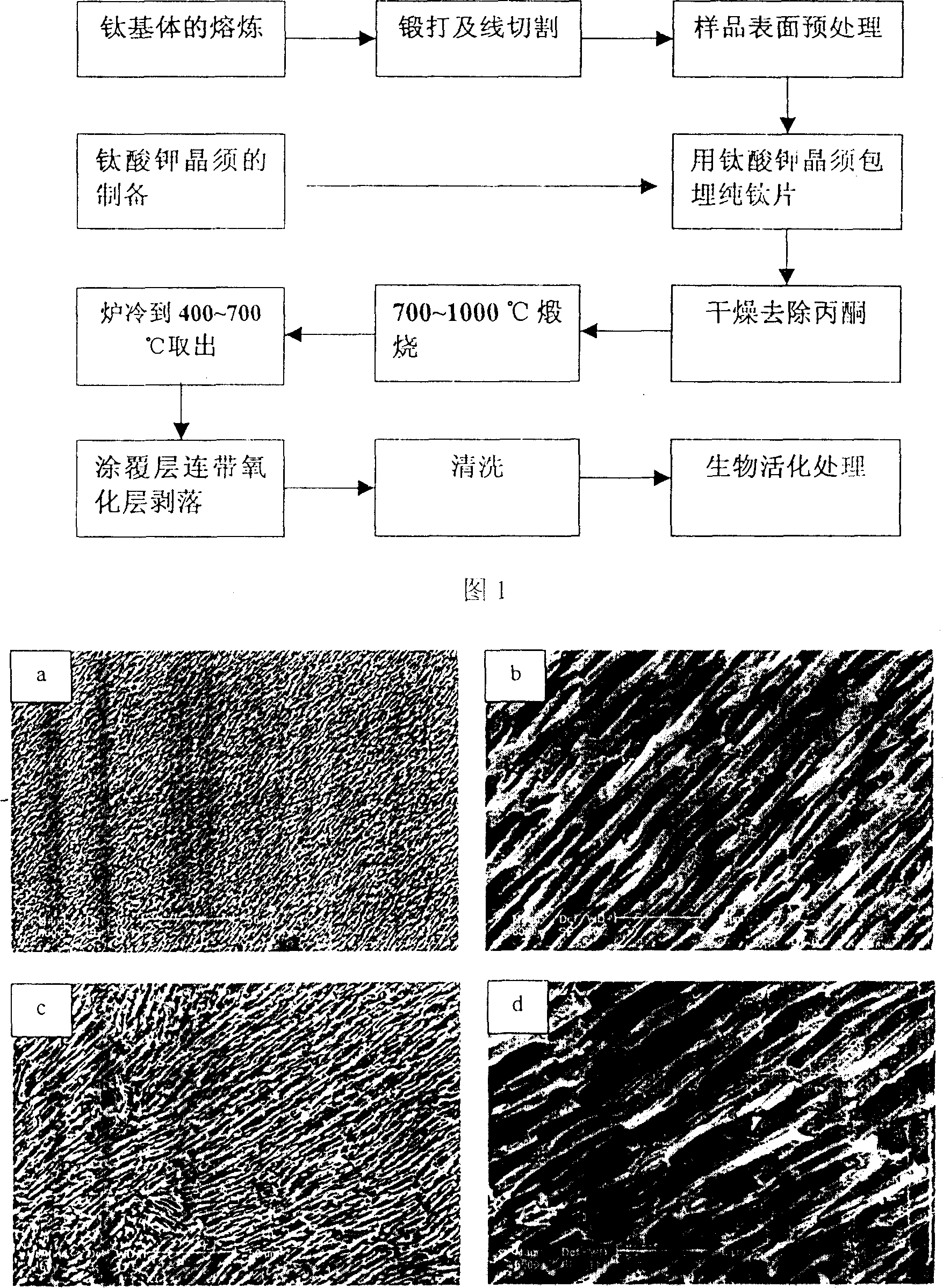

[0022] (1) Pretreatment of titanium sample surface

[0023] The titanium matrix is smelted with a non-consumable vacuum arc shell furnace, hot-forged into a long bar, and then cut into samples of the required size with a wire cutting machine, on No.280, No.400, No.600 sandpaper After polishing in sequence, put it in acetone solution and ultrasonically clean it for 10-20 minutes to remove the oil stains and wear debris on the surface, and then corrode the surface of the titanium sample with HF corrosion solution with a volume percentage concentration of 10% until the surface is dark black or gray. Then rinse with distilled water and wipe with absorbent cotton in acetone solution for later use;

[0024] (2) Preparation of potassium titanate whiskers

[0025] Using analytically pure K 2 CO 3 and TiO 2 is the raw material, and the molar ratio is K 2 CO 3 :TiO 2 =1:3~6, mix the two powdery raw materials evenly, put them into a ceramic crucible and put them into a high-temp...

Embodiment 2

[0029] (1) Pretreatment of titanium sample surface

[0030] The titanium matrix is smelted with a non-consumable vacuum arc shell furnace, hot-forged into a long bar, and then cut into samples of the required size with a wire cutting machine, on No.280, No.400, No.600 sandpaper After polishing in sequence, put it into acetone solution and ultrasonically clean it for 10-20 minutes to remove the oil stains and wear debris on the surface, and then corrode the surface of the titanium sample with HF corrosion solution with a concentration of 10% by volume until the surface is dark black or gray. Then rinse with distilled water and wipe with absorbent cotton in acetone solution for later use;

[0031] (2) Preparation of potassium titanate whiskers

[0032] Using analytically pure K 2 CO 3 and TiO 2 is the raw material, and the molar ratio is K 2 CO 3 :TiO 2 =1:3~6, mix the two powdery raw materials evenly, put them into a ceramic crucible and put them into a high-temperatur...

Embodiment 3

[0036] (1) Pretreatment of titanium sample surface

[0037] The titanium matrix is smelted with a non-consumable vacuum arc shell furnace, hot-forged into a long bar, and then cut into samples of the required size with a wire cutting machine, on No.280, No.400, No.600 sandpaper After polishing in sequence, put it in acetone solution and ultrasonically clean it for 10-20 minutes to remove the oil stains and wear debris on the surface, and then corrode the surface of the titanium sample with HF corrosion solution with a volume percentage concentration of 10% until the surface is dark black or gray. Then rinse with distilled water and wipe with absorbent cotton in acetone solution for later use;

[0038] (2) Preparation of potassium titanate whiskers

[0039] Using analytically pure K 2 CO 3 and TiO 2 is the raw material, and the molar ratio is K 2 CO 3 :TiO 2 =1:3~6, mix the two powdery raw materials evenly, put them into a ceramic crucible and put them into a high-temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com