Method for preparing polymer of butene diacid

A technology of butenedioic acid and polymer, which is applied in the field of polymer preparation, can solve the problems of non-concentrated molecular weight distribution and low molecular weight, and achieve the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Preparation of Butenedioic Acid Polymers

[0059] Polymerization takes place in the aqueous phase. The polymerization reactor is a four-necked flask equipped with a heating device, a condensation reflux device, a stirring device and a thermometer.

[0060] Add monomer, catalyst and water into the four-neck flask, after the solid material is completely dissolved, heat up to the reaction temperature, add the initiator dropwise to start the polymerization reaction, stop heating after a certain period of time, cool the reactant to normal temperature, and obtain the polymerization product.

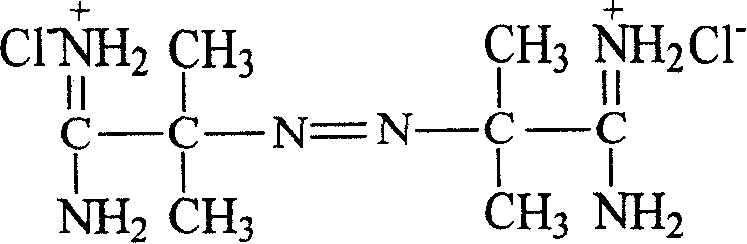

[0061] The monomer is maleic anhydride, the catalyst is ferric ammonium sulfate, and the initiator is amidinoisopropyl azo hydrochloride and hydrogen peroxide.

[0062] The concentration of monomer in aqueous solution is 40% weight, and the concentration of catalyzer in aqueous solution is 200mg / L, and the add-on of initiator hydrochloric acid amidinoisopropyl azo is 1.0g / mol monomer, a...

Embodiment 2

[0074] The polymerization reactor and the polymerization process were the same as in Example 1.

[0075] The monomer of the polymerization reaction is maleic anhydride, the catalyst is ferric ammonium sulfate, the initiator is amidinoisopropyl azo hydrochloride and hydrogen peroxide.

[0076] The concentration of the monomer in the aqueous solution is 10% by weight, the concentration of the catalyst in the aqueous solution is 100mg / L, the addition of the initiator amidinoisopropyl azo hydrochloride is 0.1g / mol monomer, and the amount of the initiator hydrogen peroxide The addition amount is 9 g / mol monomer; the aqueous phase of the polymerization reaction also contains phosphorous acid, and its phosphorus content is 0.1% of the total weight of the monomer.

[0077] The adding method of the initiator is as follows: add amidinoisopropyl azo hydrochloride into aqueous hydrogen peroxide solution (concentration is 30% by weight), and after completely dissolving, add dropwise into t...

Embodiment 3

[0081] The polymerization reactor and the polymerization process were the same as in Example 1.

[0082] The monomer of the polymerization reaction is maleic anhydride, the catalyst is ferric ammonium sulfate, the initiator is amidinoisopropyl azo hydrochloride and hydrogen peroxide.

[0083] The concentration of the monomer in the aqueous solution is 60% by weight, the concentration of the catalyst in the aqueous solution is 500mg / L, the addition of the initiator amidinoisopropyl azo hydrochloride is 10g / mol monomer, the addition of the initiator hydrogen peroxide The amount is 60 g / mol monomer; the aqueous phase of the polymerization reaction also contains hypophosphorous acid whose phosphorus content is 10% of the total weight of the monomers.

[0084] The adding method of initiator is: at first amidinoisopropyl azo hydrochloride is added in the aqueous phase containing monomer and catalyst, after dissolving completely, hydrogen peroxide (concentration is 30% by weight) is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com