A kind of water-in-water type amphoteric polyacrylamide emulsion and preparation method thereof

A technology of polyacrylamide and acrylamide is applied in the field of water-in-water amphoteric polyacrylamide emulsion and its preparation, and achieves the effects of simple method, improved adsorption speed and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention provides a kind of preparation method of water-in-water type amphoteric polyacrylamide emulsion in the first aspect, described method comprises the following steps:

[0030] (1) Acrylic acid is neutralized with sodium hydroxide to obtain a mixture containing acrylic acid and sodium acrylate;

[0031] (2) The mixture containing acrylic acid and sodium acrylate, acrylamide monomer, cationic monomer, compound dispersant composed of nonionic dispersant and amphoteric dispersant, surfactant, at least a part of inorganic salt, hydrophobic monomer Body, chelating agent and water (such as deionized water or distilled water) are mixed homogeneously to obtain a solution; and

[0032] (3) Nitrogen is passed through the solution obtained in step (2) to remove oxygen, then an initiator is added to initiate a polymerization reaction, and then aging and salting out are performed to obtain a water-in-water type amphoteric polyacrylamide emulsion.

[0033] In the pr...

Embodiment 1

[0057] ① Preparation of amphoteric dispersant: Mix 40 parts by weight of acrylamide, 160 parts by weight of acrylic acid, 25 parts by weight of dimethyl diallyl ammonium chloride, 0.35 parts by weight of sodium formate and 687 parts by weight of water to obtain a mixed solution; 88 parts by weight of sodium hydroxide to adjust the pH of the mixed solution to 6.8, and then keep it warm in a water bath at 50°C, then pass nitrogen to remove oxygen for 30 minutes, and then add 0.4 parts by weight of azobisisobutylamidine hydrochloride to initiate the polymerization reaction 2h to prepare the amphoteric dispersant P(AM-DMDAAC-AA). The rotational viscosity of the amphoteric dispersant P (AM-DMDAAC-AA) measured with a rotational viscometer at 25°C was 97500 mpa·s.

[0058] ②Preparation of water-in-water type amphoteric polyacrylamide emulsion: After neutralizing 22.5 parts by weight of acrylic acid with 10 parts by weight of sodium hydroxide to pH 5.7, mix with 150 parts by weight of...

Embodiment 2

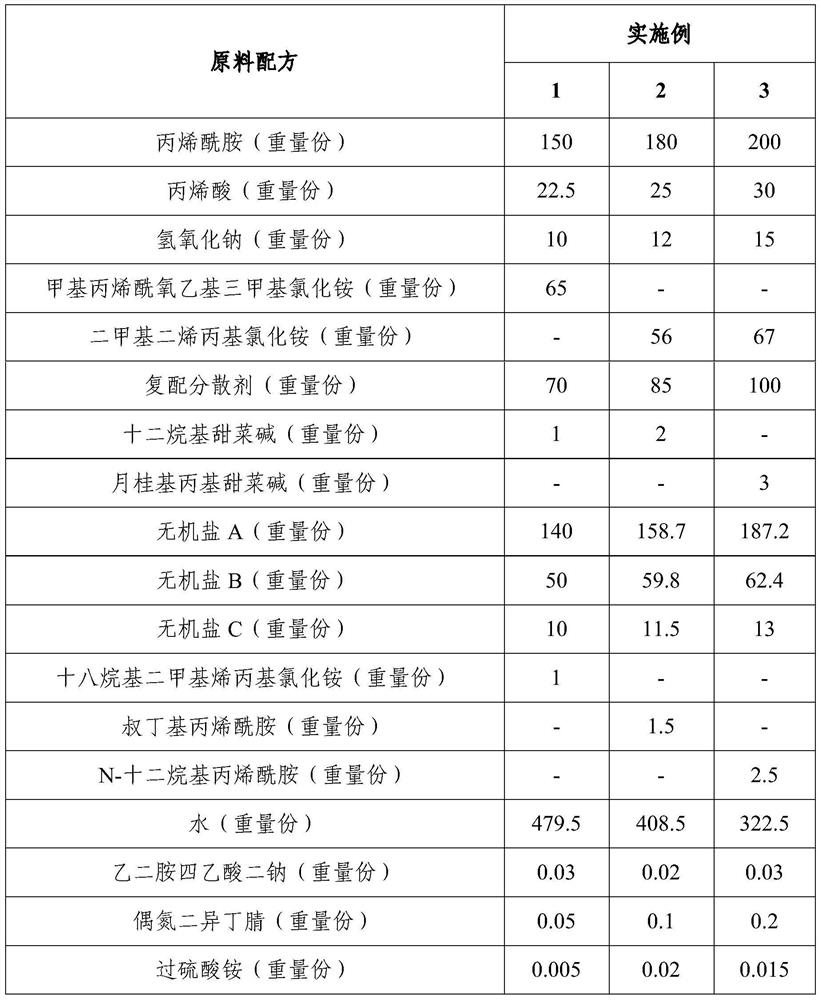

[0060] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0061] The raw material formulations are different, as shown in Table 1;

[0062] In ②, neutralize acrylic acid to pH 5.5 with sodium hydroxide;

[0063] In ②, adjust the final pH of the resulting solution to 5.8 with sodium hydroxide;

[0064] In ②, after purging nitrogen and deoxygenating for 10 min, the initiator was added at 34°C to initiate the polymerization reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com