Preparation method of graft-reinforced nitrile butadiene rubber

A technology of nitrile rubber and nitrile rubber, which is applied in chemical instruments and methods, compounds of group 4/14 elements of the periodic table, organic chemistry, etc. It can solve the difficulty in controlling the polymerization process and the large difference in the reactivity rate of monomers , Polymerized monomer components are complex and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

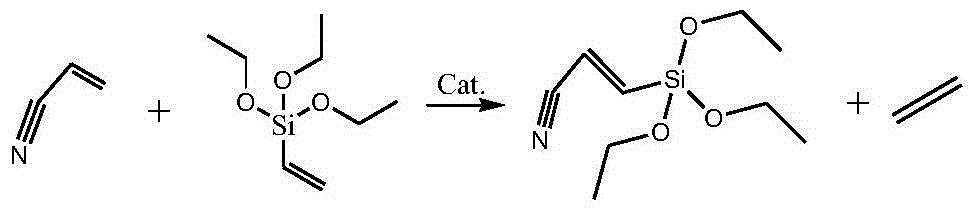

[0032] Acrylonitrile and vinyltriethoxysilane monomers are mixed in a molar ratio of 1:1, and a monomer solution with a mass concentration of 10% is configured with toluene solvent, and 0.05% mol of the monomer is added to the solution Catalyst, isolated from air and water, react at room temperature for 2 hours, use a vacuum desolventizer to remove the toluene solvent, and obtain a nitrile rubber reinforcing agent.

[0033] Add nitrile latex (100 parts on a dry basis), 5 parts by mass of the above-mentioned rubber reinforcing agent and 0.01 parts by mass of potassium persulfate initiator to the polymerization kettle, control the reaction temperature to 60 ° C, react for 3 hours, and after the reaction The emulsion is coagulated, washed and dried to obtain high-strength nitrile rubber products. After testing, compared with the tensile strength of ordinary nitrile raw rubber (18.5 MPa), the tensile strength of the enhanced nitrile raw rubber of Example 1 is 25.5 MPa, which is 3...

Embodiment 2

[0038] Mix acrylonitrile and vinyldiethoxymethylsilane monomers at a molar ratio of 1:0.1, configure a monomer solution with a mass concentration of 30% with toluene solvent, and add 0.1% mol of monomers to the solution Catalyst, isolated from air and water, react at room temperature for 8 hours, use a vacuum desolventizer to remove the solvent, and obtain a nitrile rubber reinforcing agent.

[0039]Nitrile latex (100 parts on a dry basis), 45 parts by mass of the above-mentioned rubber reinforcing agent and 0.1 parts by mass of benzoyl peroxide initiator were added to the polymerization kettle, and the reaction temperature was controlled to be 40° C., and the reaction was carried out for 5 hours. The reacted emulsion is coagulated, washed and dried to obtain a high-strength nitrile rubber product. After testing, compared with the tensile strength of ordinary nitrile raw rubber (19.6 MPa), the tensile strength of the enhanced nitrile raw rubber of Example 2 is 25.9 MPa, which...

Embodiment 3

[0044] Mix acrylonitrile and vinyltrimethoxysilane monomers at a molar ratio of 1:5, configure a monomer solution with a mass concentration of 1% with toluene solvent, and add 0.10% mol of monomers to the solution Catalyst, isolated from air and water, react at room temperature for 0.5h, and use a vacuum desolventizer to remove the toluene solvent to obtain a nitrile rubber reinforcing agent.

[0045] The nitrile latex (100 parts on a dry basis), the above-mentioned rubber reinforcing agent of 15 parts by mass and the cumene peroxide initiator of 0.08 parts by mass were added to the polymerization kettle, and the reaction temperature was controlled to be 65 ° C, and the reaction was carried out for 10 hours. The reacted emulsion is coagulated, washed and dried to obtain a high-strength nitrile rubber product. After testing, compared with the tensile strength of ordinary nitrile raw rubber (20.2MPa), the tensile strength of the enhanced nitrile raw rubber of Example 3 is 25.4M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com