Water fluorine carbon emulsion paint and preparation process thereof

A latex paint, water-based fluorocarbon technology, applied in latex paint, coating, etc., can solve the problems of environmental pollution, low fluorine content, opaque latex film, etc., and achieve the effect of solving environmental pollution, excellent weather resistance, and no solvent odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

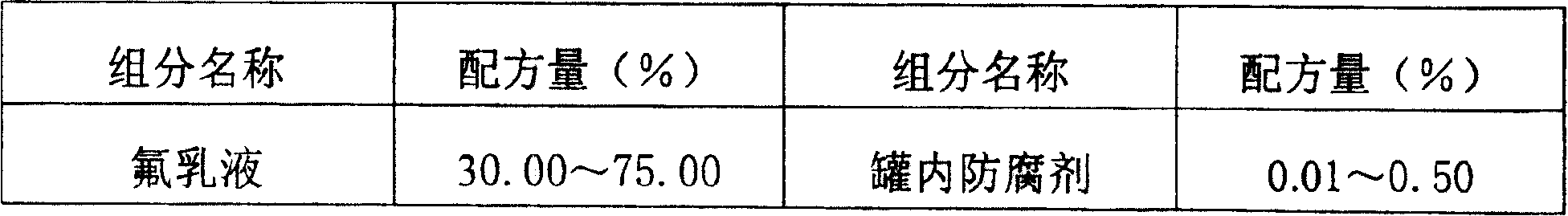

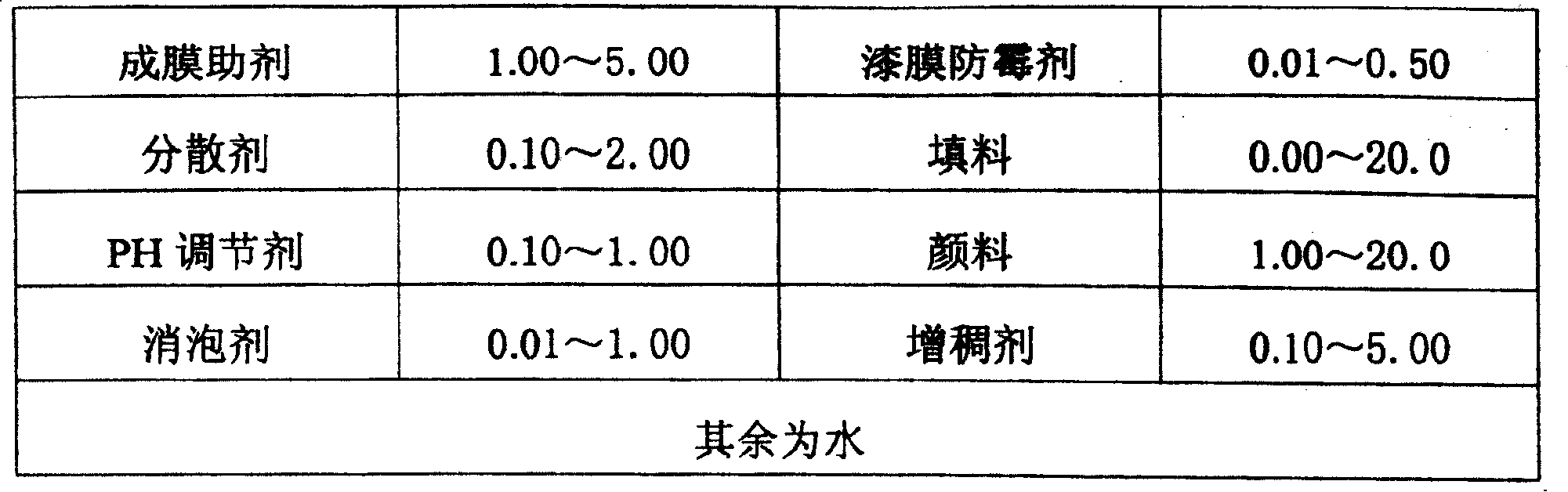

Method used

Image

Examples

Embodiment 1

[0022] Add 33.00g of water into the batching tank according to the names and proportions of raw materials listed in Table 3, and add 10.00g of dispersant, 1.00g of defoamer, 0.50g of preservative in the tank, and 0.50g of paint film antifungal agent respectively under stirring , after stirring evenly, add 5.00g of pH adjuster to adjust the pH value of the system, after the pH value reaches the range of 8.0-9.0, add imported rutile titanium dioxide, mix well and pump the material into a sand mill for grinding. Fineness ≤ 50μm, then add 700.0g of SE-350 emulsion, slowly and uniformly add 50.00g of film-forming aid under stirring, add 40.00g of thickener according to the viscosity requirements of the coating, and use 80-100 mesh screen when the product reaches the standard Filter and pack to get the finished product.

Embodiment 2~7

[0024] Adopt the same method as embodiment 1 to prepare water-based fluorocarbon latex paint, the names of raw materials used in embodiments 2-7 and the proportioning ratio as shown in table 3.

[0025] The solid content of the water-based fluorocarbon emulsion used in Examples 1-7 is 40-50%, and the fluorine content of the solvent-soluble matter is 40%.

[0026] The main performance test results of the water-based fluorocarbon latex coatings prepared according to Examples 1 to 7 are shown in Table 4:

[0027] Table 4

[0028]

Test items

Example

1

Example

2

Example

3

Example

4

Example

5

Example

6

Example

7

Tu Mo Appearance

normal

normal

normal

normal

normal

normal

normal

Drying time (surface dry), h

≤2

≤2

≤2

≤2

≤2

≤2

≤2

Contrast Ratio (White and Light)

0.94

0.94

0.95

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com